16

SETTING OF ALARM RESUME TIME

The alarm buzzer and remote alarm are stopped by pressing alarm buzzer stop key (BUZZER) on the

control panel during alarm condition. The buzzer and remote alarm will be activated again after certain

suspension if the alarm condition is continued. The suspension time can be set by following the

procedure shown in the Table 5 below.

The example in the table is based on the assumption that the desired duration is 20 minutes.

Note:

The duration is set in 30 minutes at the factory.

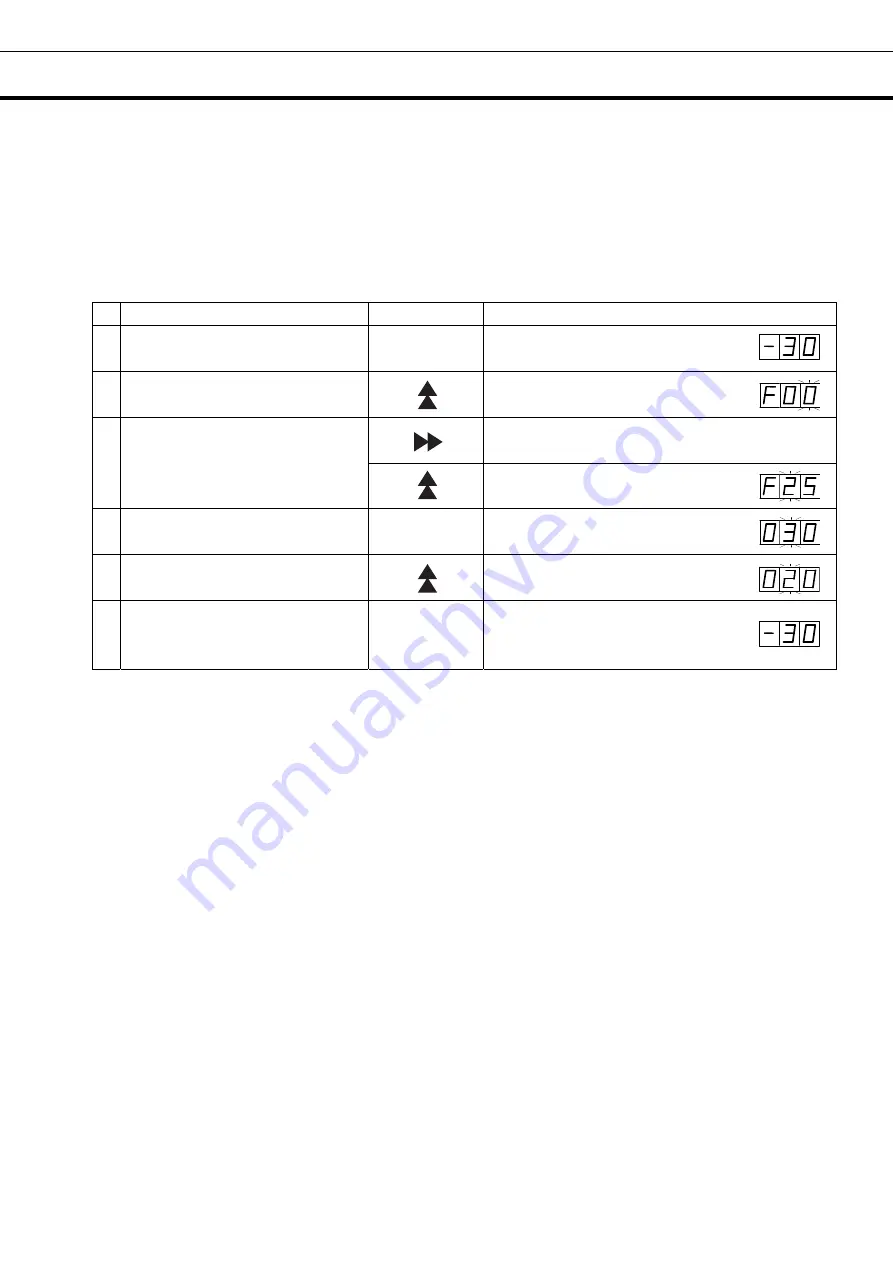

Table 5 Setting procedure for alarm resuming time (change from 30 minutes to 20 minutes)

Description of operation

Key operated

Indication after operation

1

----

The current chamber temperature is

displayed.

2

Press numerical value shift key for

5 seconds.

The first digit is flashed.

3

Set the figure to F25 with the

digit shift key and numerical value

shift key.

When pressed, the changeable digit

is shifted.

When pressed, the figure of settable

digit changes.

4 Press set key.

SET

The current resume time is displayed.

The second digit is flashed.

5

Set the figure to 020 with the

numerical value shift key.

When pressed, the figure of settable

digit changes.

6 Press set key.

SET

The setting is memorized and

the current chamber temperature is

displayed.

The settable alarm resume time are 10, 20, 30, 40, 50, or 60 minutes (The setting is 010, 020, 030,

040, 050, or 060). The buzzer and remote alarm would not resume if the resume time is set in 000.

The setting of alarm resume time cannot be changed during the defrosting.

The setting mode returns to the temperature display mode automatically when 90 seconds has passed

without any key operation. In this case, any setting before pressing set key (SET) is not memorized.

Summary of Contents for MDF-MU300H

Page 2: ......