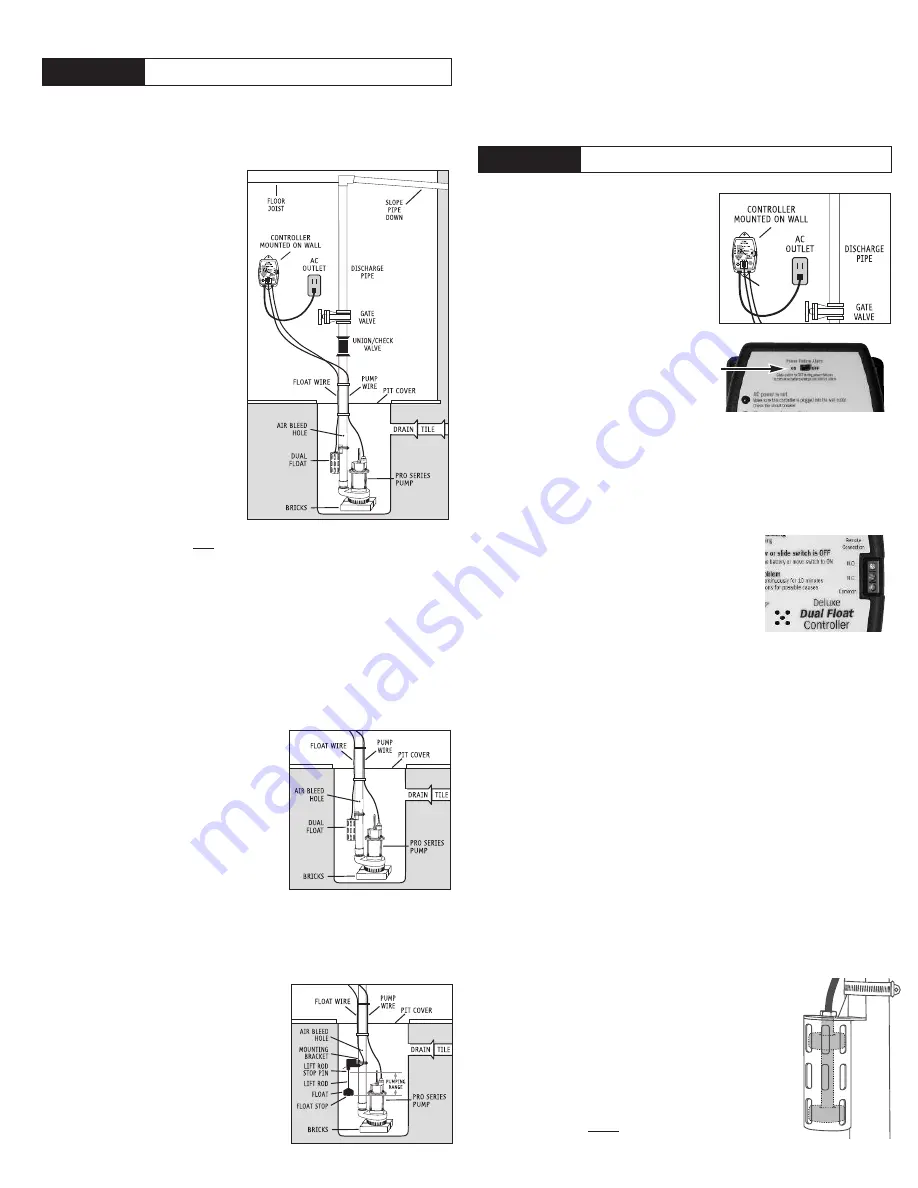

Installing the Pump

1. Use a pit that conforms to all local codes and is large enough to accommodate the pump

and float switch. The minimum requirements for pumps with the double float assembly are

10” in diameter and 14” deep. However, larger sump pits are preferred, since they will

extend the discharge cycle and reduce the number of times the pump turns on.

2. Clean the pit of all debris. The pump’s intake screen must be kept clear.

3. The pump should not be set directly

onto a clay, earthen, or sand base. You

may install bricks or blocks under the

pump to provide a solid base.

4. The pump should be level.

5. Install discharge plumbing according to

local, regional and state codes. Rigid

PVC pipe is recommended.

6. The sizes of the discharge outlets on the

pumps vary from 1

1

⁄

2

“ to 2“. Try to

match the size of the discharge pipe to

the size of the outlet on the pump to

maintain the optimum pumping

capacity. If you are using a PHCC Pro

Series pump with a 2“ discharge outlet

to replace a pump in a system that has

been plumbed with 1

1

⁄

2

“ pipe, you may

use the adapter included with the

system to reduce the size of the

discharge outlet to 1

1

⁄

2

“. However, this

will reduce the capacity of the pump.

7. An in-line check valve is recommended

to prevent back-flow. This check valve

is mandatory when sharing a discharge

line with another pump (i.e. a back-up

pump or a second primary pump).

Note:

When using a check valve, an air bleed

hole of

1

⁄

8

“

(3.2mm) needs to be drilled

in the discharge pipe. The hole must be drilled above the water line but below the check

valve. A small stream of water will escape through this air bleed hole when the pump is

running, so the hole should be drilled on an angle toward the bottom of the sump pit.

8. Install a gate valve or ball valve as required by any codes.

9. Secure the power cord to the discharge pipe with wire ties or clamps to prevent

interference with the float assembly.

10. A pit cover is recommended for all installations as a safety measure, and to prevent

debris from falling into the pit.

11. A cover is required in all sewage pump installations with gas-tight seals to contain gases

and odors. A vent pipe should be added in any sewage installation.

12. In instances where the discharge line is exposed to freezing temperatures, the pipe must

be positioned in a downward slope so any remaining water will drain away. Failure to do

this will prevent water from exiting the pit and damage the pump if the line freezes.

Installing the Double Float

The PHCC Pro Series double float switch is easy to

install by using the enclosed metal hose clamp.

1. Hold the float switch to the discharge pipe so the

cage is below the bracket.

2. Secure the float to the pipe with the enclosed

hose clamp, but do not completely tighten the

clamp at this time.

3. Position the float switch to a level where the

bottom of the float cage is no lower than 3“

above the bottom of the pump and no higher

than 1“ below the top of the pit. To avoid debris

pouring into the float, it should be positioned on

the side of the discharge pipe opposite the drain tile.

Note: It is important to mount the

float below the drain tile that empties into the pit. Mounting it above the drain tile would

allow water to fill the drain tile before the pump is activated to pump out the water.

4. Once the float switch is in the desired position, tighten the clamp.

Installing the Vertical Float

The vertical float switch contains a single large float.

Water will lift the float to the top of the lift rod

which will raise the lift rod and activate the pump.

As the pump evacuates the water from the pit the

float will drop, lowering the lift rod and turning off

the pump.

1. Fully open the metal hose clamp and insert it

through the slots in the mounting bracket of the

float switch.

2. Place the hose clamp over the discharge pipe so

that the gripping tabs are against the pipe and

select the desired activation level of the pump.

3. The pumping range can be adjusted by moving the float stop up or down the lift rod.

4. To avoid debris from pouring onto the float, it should be positioned on the side of the

discharge pipe opposite the drain tile.

5. Once the float switch is in the desired position, securely tighten the hose clamp. Note:

The cable from the switch must remain outside the hose clamp.

Connecting the Pump and Controller

Deluxe Dual Float Controller Model # DFC2

1. Mount the controller to the foundation, drywall

or a stud through the 2 holes on the cabinet

using the proper mounting hardware for the

application. The controller should be mounted

at least 4’ from the floor and within 4’ of the

outlet.

2. Open the plastic door on the top of the unit and

using a small flat head screwdriver adjust the

dial to select the number of seconds that the

pump will run after the bottom float drops. The

timer can be adjusted from 5-45 seconds. The

manufacturer default is about 10 seconds.

Install a 9V battery and replace the door.

3. Plug the control box into a properly grounded,

3-prong receptacle. Then, plug the pump into

the receptacle on the control box. Do not use an extension cord.

4. Make sure the Power Failure Alarm slide switch is in the ON position.

Vertical Float Switch Model # 1020012

1. Plug the vertical float switch cord into a properly grounded 3-prong receptacle. Then, plug

the pump into the receptacle on the float switch cord. Do not use an extension cord.

Connecting to a Security System

The Deluxe Controller (Model DFC2) includes a terminal on the

right side of the control box to connect to a security system

or other alarm devices. There are (3) three positions for wire

connections on this terminal: N.O. – normally open, N.C. –

normally closed, and Common.

1. Check your security system to determine whether an open

(no contact) or closed (making contact) connection is

needed to activate the alarm.

2. The security system will provide (2) two connection terminals to extend wires to the

control terminal. Strip two wires 1/4“ each. Connect either wire to the common

terminal. To secure the wire into the terminal, insert the exposed wire into the hole on

the side of the terminal next to the screw marked common. Turn the screw a few turns to

lock-in the wire.

3. If the security system requires a closing of a contact to activate the alarm, secure the

other wire into the terminal hole labeled N.O. (normally open). If the security system

requires an opening of a contact, secure the wire into the terminal hole labeled N.C.

(normally closed).

Note: Only the “AC power out” and ‘Float raised for 10 minutes” alarms

will activate the remote

terminal signal.

Completing the Installation

(all models)

1. After the initial installation, be sure to check the pump operation by filling the sump with

water and observing the pump through one full cycle. When using the dual float the pump

should run for 10 seconds after the lower float drops. When using the tethered float the

pump should shut off when the float is tilted down.

Note: When the pump activates, it

should have a “normal pumping” sound. Any abnormal sound, vibration, or lack of output is

the signal of a problem. Stop the pump and refer to the troubleshooting guide.

2. Replace the pit cover making sure not to pinch or crimp the pump wire with the cover.

The pit cover either has a ‘hole punch’ that will allow the cord to be passed through or

one can be drilled.

Product Operation

Dual Float Switch

(included with controller models DFC1, DFC1.5 and DFC2)

The dual float switch contains two large floating rings enclosed

within a protective cage. Water will lift the bottom float by a

1

⁄

4

“,

which will activate the pump. If for any reason the lower float does

not activate the pump, the water will rise and activate the second

switch. As the pump evacuates the water from the pit the floats

will drop. The pump will run for an additional 10 seconds to extend

the cycle after the lower float drops.

Note: When mounting the

float switch, position the bottom of the cage at the height you want

the pump to activate.

WARNING

WARNING

This installation must be in accordance with the National

Electric Code and all applicable local codes and ordinances.

Make sure the outlet is single phase, 115V and 60HZ for all

the pump installations.

PUMP

WIRE

2