on the turntable, the position of the free end of the bracket (2) must be corrected by bending it upwards

or downwards. The PU-ARM is now set in such a way that when it is placed above the turntable, the

needle

just passes over the hairs of the felt

. Care must be taken that the plastic disc

(2) -VIII

does not

touch the blade (2a) -VIII when the needle is resting on the plate, otherwise the free horizontal

movement of the PU arm is impeded (mutual distance approx. 0.3 mm).

............

843582

2.

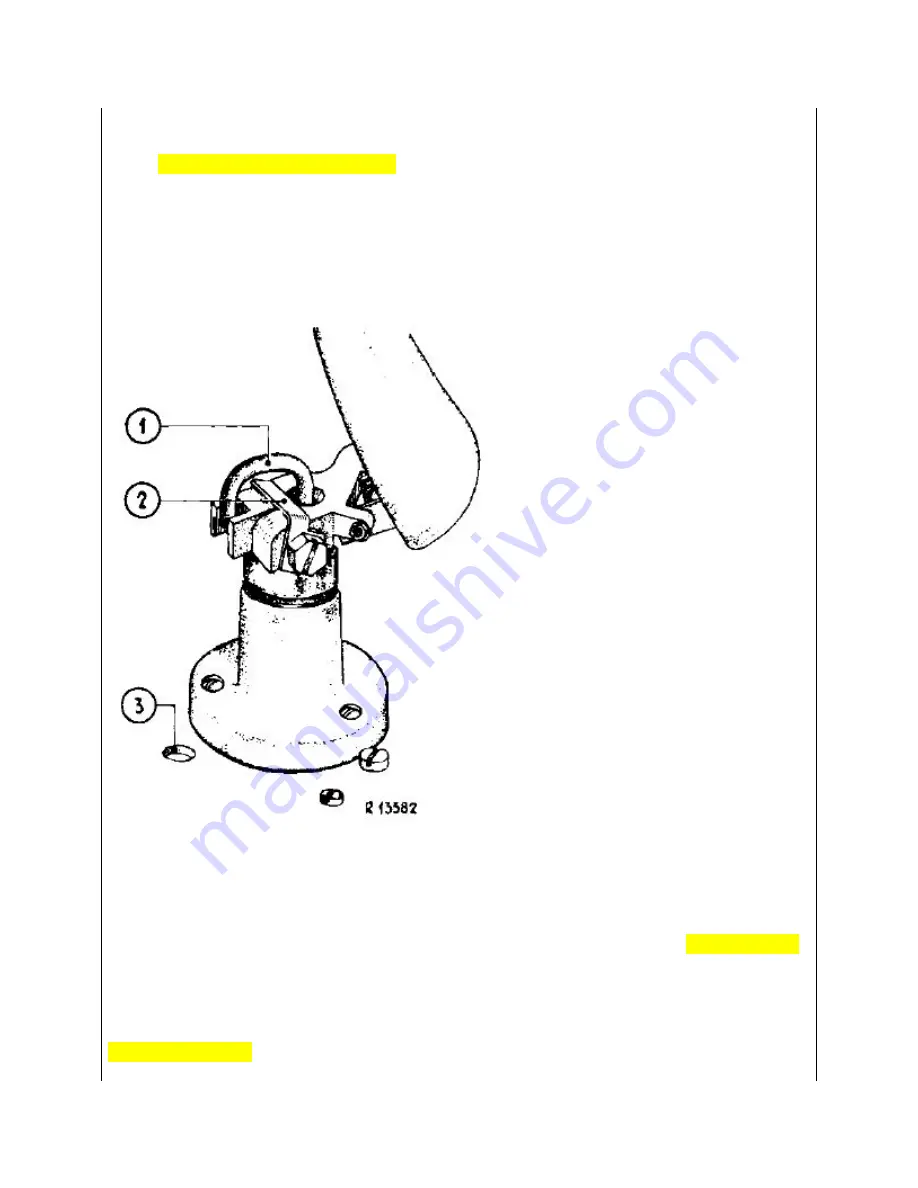

The friction of the taker (1) -VI is too large and needs to be adjusted. In order to do this, the PU-arm

must be placed on the support of the start switch, making it possible to

reach a screw

through the hole

(

3

) in the mounting plate, with which the friction can be adjusted. If a

Yeard pressure meter

is available,

the friction can be adjusted to 2 grams. This is measured on point

the center of the driver (1) -VI. If such an instrument

is not available

, the adjustment must take place in

the following manner

.

47

Summary of Contents for AG1000

Page 29: ...See also DSC00130 jg and stitched 00125 00128 and zippy1 fig 6 jpg 29 ...

Page 56: ...56 ...

Page 61: ...Runnells IA usa c60h hotmail com 61 ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

Page 65: ...FIG 8 65 ...

Page 66: ...FIG 8 FIG 9 66 ...

Page 67: ...FIG 9 67 ...

Page 68: ...68 ...

Page 69: ...THERE IS NO 32 THRU 40 WAS NONE 69 ...

Page 70: ...70 ...

Page 71: ...71 ...