5-2

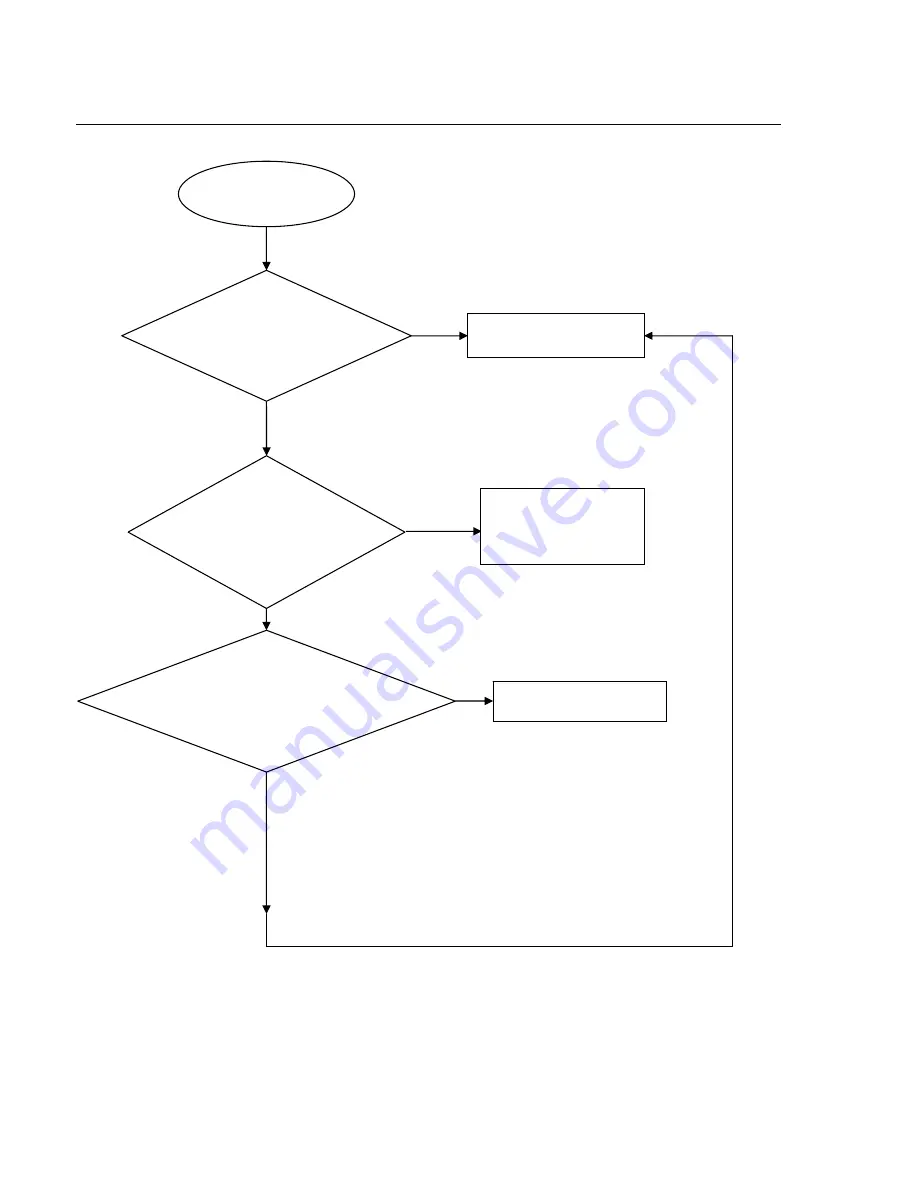

The power can not be on or off

Go

Yes

Yes

No

No

The power can’t be

on or off

Yes

Repair the power board

Check the power supply

on the power board is

normal.

Check/Correct

connection

Check if the xp1 on the

decoderboard to XS301 on the

frontboard is in good contact

Correct the connection

No

Yes

Check if the CON2 on the

power board to XP2 on the

decoder board is in good

contact.

Trouble shooting chart

Summary of Contents for DVP3320

Page 32: ...Front Board Switch Board Print layout Bottom side 7 9 7 9 ...

Page 33: ...OK Board Print layout Top side OK Board Print layout Bottom side 7 10 7 10 ...

Page 34: ...Power Board Print layout Bottom side 7 11 7 11 ...

Page 35: ...Main Board Print layout Top side 7 12 7 12 ...

Page 36: ...Main Board Print layout Bottom side 7 13 7 13 ...

Page 39: ...REVISION LIST Version 1 0 Initial release for DVP3320 55 9 1 ...