mounting & supply cable connections

5

DNG485 Instruction Manual Rev F.doc

Select A Suitable Location

This device is designed for indoor use only. If

installing in an external location, the DNG485

must be housed in a suitable well-ventilated

enclosure. Choose a dry location that will be

accessible after the installation is complete.

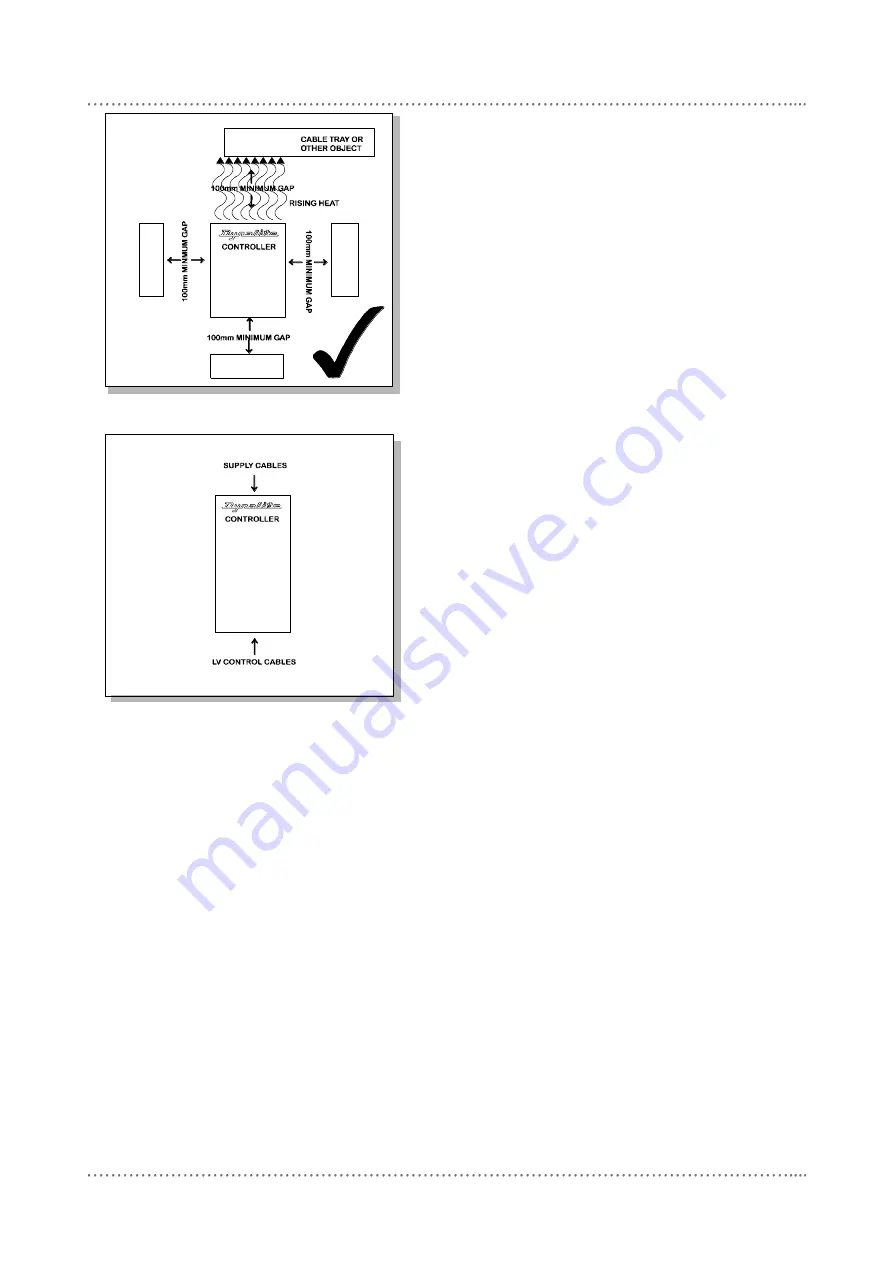

The DNG485 should be mounted with an air

gap of 100mm on each side and at the top

and bottom of the device. This air gap is

required to ensure the serviceability of the

DNG485 without its complete removal from

the mounting surface and to enable access to

the service switches and LEDs.

Fixing the Device

The DNG485 has integral mounting brackets

attached to the enclosure, designed to

accommodate 4 fixing screws up to 8mm

diameter. The DNG485 can be fixed to the

wall without opening the cabinet or removing

covers. Make sure no dust or other debris

enters the device during installation. Do not

leave the front cover off for any length of

time. Excessive dust and dirt can degrade

internal components.

Allow For Cable Entry

Supply cables enter the enclosure at the top.

If these cables are fed from below the

mounting position, they should be routed

around the enclosure to enter at the top. The

control cables enter at the bottom of the

enclosure. Control cables should never be

run in the mains voltage sections of the

enclosure.

Supply Cable Connections

The supply terminals are located toward the

centre of the enclosure and consists of

Neutral, Phase and an Earth link which will

accept up to two 2.5mm

2

cables. The supply

cables should have a capacity of 0.5 Amps

minimum. This device must be earthed.