connecting serial control cables

DNG485 Instruction Manual Rev F.doc

6

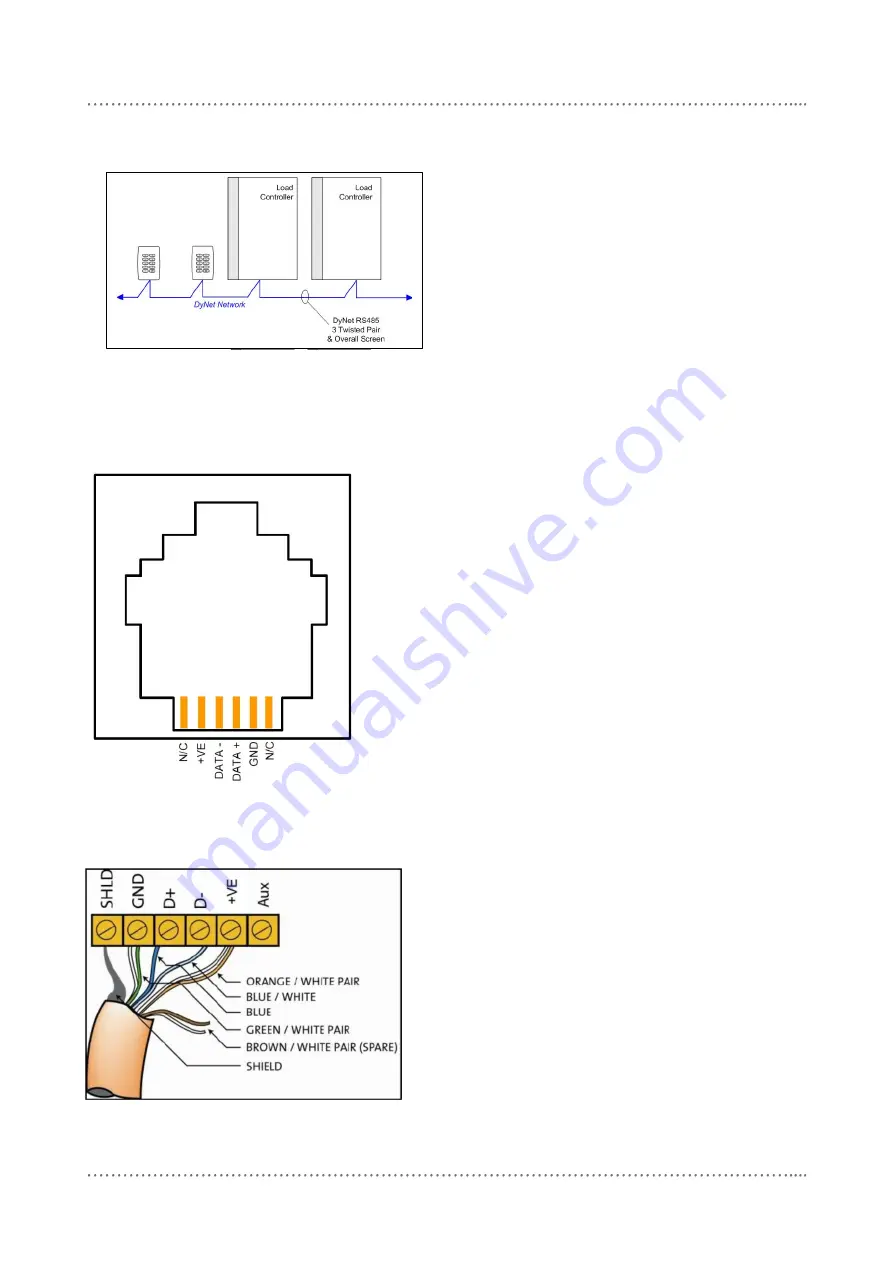

Serial Cable Connections

There is one RS485 port for DyNet signals, in the

form of a RJ12 socket, on the front panel, which is

used for the temporary connection of a PC or a

Portable Programmer (DPP601). There are data

terminals on the control card, for permanent

connections.

The

recommended

cable

for

connections to the serial port is screened,

stranded RS485 data cable with three twisted

pairs. Recommended cable types include:

Belden:

9503

Dynalite

DYNET-STP-CABLE

Garland:

MCP3S

Hartland:

HCK603

M&M Cable:

B2003CS

M&M Cable:

B9503CS

Multicables:

AWM E120236 2092 20

RS Components: 368-687

Dynalite

DYNET-STP-CABLE

One pair is paralleled for GND, one pair paralleled

for +VE, and one pair used for DATA+ and DATA-

.

Recommended

Cable Colour-Coding

Green/White pair

Paralleled for GND

Orange/White pair

Paralleled for +VE

Blue/White pair

Blue for DATA+

White for DATA-

Brown/White pair

Spare or Shield

If using unshielded cable terminate the brown pair

to the Shield terminal. The colour-coding scheme

used is not critical, as long as the same scheme is

used throughout the installation.

Serial Cable Connecting Method

The recommended connec

ting method is to „daisy

chain‟ devices (ie. starting at the first device, then

looping in then out of devices, with a single cable

terminating at the last device. There should not

be any spurs or stubs, and only the first and last

device should terminate one cable, all other

devices should terminate two cables). Devices

may be wired in any order. The Data Cable

should be segregated from any Mains Cables by

at least 300mm, or to meet local wiring rules.

A

data cable that is connected to an energised

dimmer is live. Do not cut or terminate live data

cables.

If the Data Cable has to cross over any

Mains Cables, it should do so at a 90

angle.

Connections for the Left & Right Ports

The Left port is the preferred port for connection

to Dynalite devices such as dimmers and smart

panels on a spur. The Right port is the preferred

port for connection to a data trunk or backbone,

and

third

party

devices

such

as

AV

controllers/touch screens and BMS.

Serial Cable Permanent Connections

Connect Data Cable in a ‘Daisy Chain’

RJ12 Socket Connections