troubleshooting

7

DNG485 Instruction Manual Rev F.doc

Check the following list. If you are still unable to rectify the situation, contact your nearest Dynalite

office. A complete list of distributors worldwide can be found on the Internet at:

Please ensure that you have completed the following prior to calling

our technical support department:

Check all symptoms in the Troubleshooting list

Check for any deviations between the installation and the installation instructions

Make a list of the model numbers of all devices used in the system

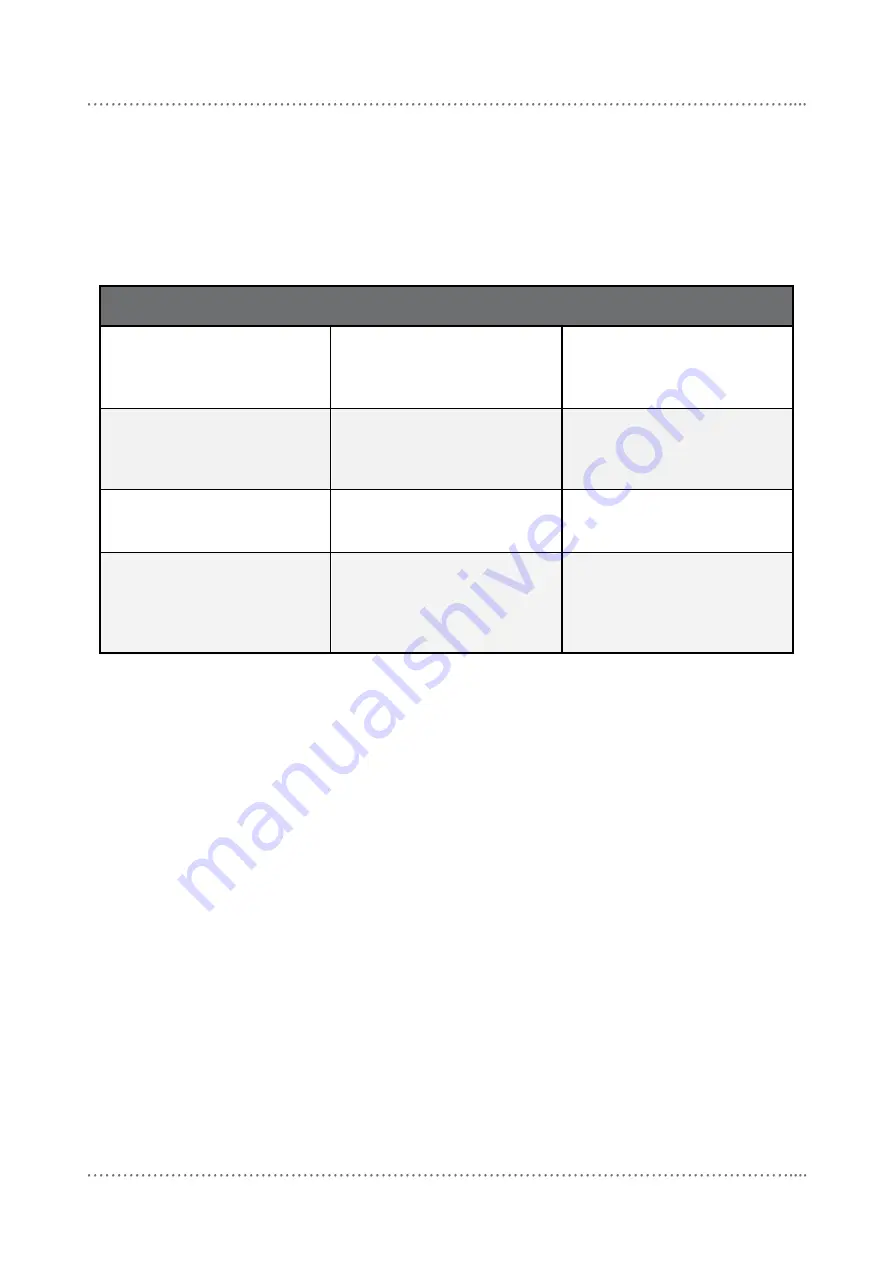

SYMPTOM

PROBABLE CAUSE

ACTION

Device does not operate at

all. No Service LED activity.

Power supply indicator LED

on PCB not lit.

Incorrect connection of

Mains supply, or no power

available.

Check power supply to

DNG485. Check Line and

Neutral input connections.

Check Fuse if fitted.

Power supply indicator LED

lit, but no Service LED

activity.

Supply voltage too low, short

circuit on network or short

circuit on analogue inputs.

Control PCB faulty.

Check 5V & 12V terminal

voltages. Disconnect network

bus and restore power.

Replace control PCB.

Device appears to be

operating but not passing

messages.

Incorrect Dip Switch settings.

Faulty LTC485 Transceiver.

Verify Dip Switch settings.

Replace LTC485

Transceiver.

Device passes messages in

one direction only.

Incorrect Dip Switch settings.

Incorrect software

configuration. Message Pass

Filter incorrectly set.

Verify Dip Switch settings.

Reload device & verify

Message Pass Filter

settings. Re compile event

file.