Service Modes, Error Codes, and Fault Finding

EN 20

EM5.2E AA

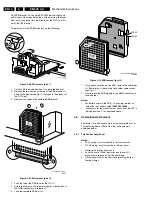

5.

Take care not to touch the "hot" heatsink while disconnecting

the SSB, despite the fact that the mains cord is out of the mains

socket. There can still be an annoying rest-voltage on the

heatsink for a short while. This, because the discharge

resistors 3502 and 3503 (on the LSP between hot and cold

part) are not stuffed for Europe. Instead, discharge resistors

3066 and 3057 on the Mains Switch panel are used, but

because they are located before the Mains switch, they only

discharge when this switch is "on".

Advice:

when you remove the SSB, disconnect the Mains

cord, but keep the Mains Switch "on".

Do not try to measure on the SSB side, which is facing the 'hot'

heatsink. This is dangerous. Most service test points are

guided to the 'tuner' side and are indicated by the 'service'

printing.

Where the circuitry was too "crowded" for service printing, you

can find the correct location on the "test point overviews" in this

manual.

A very large part of the LSP is "

hot

", such as:

•

The primary part of the Standby Supply.

•

The whole Main supply (except for the secondary Audio

supply).

•

And the complete deflection circuitry (so notice that the

deflection coil is hot!).

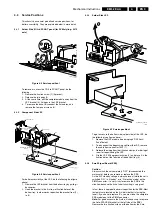

5.8.2

Start-up Sequence

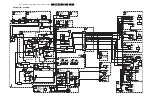

Figure 5-4 Start-up circuitry

The start up sequence differs from other sets (e.g. MG-sets or

EM2E-sets, but is same as in EM3E-set):

1.

When the set is switched "on", the 5 and 8 V lines

("+5V_CON" and "+8V_CON") of the standby power

supply are activated.

2.

After the OTC senses them, the P will address the HOP via

the I

2

C

-bus, to start the drive [1].

3.

Via the "SUP-ENABLE" signal, the Main Supply is switched

"on" and will deliver the V_BAT to the Line deflection stage

[2].

4.

EHT generation is now started.

5.

The OTC will un-blank the picture.

6.

When you switch "off" the set, this is done in a controlled

way via the POR signal [3].

Note:

Standby is not directly achieved via the Standby line of

the microprocessor, but indirectly via the HOP circuitry.

5.8.3

ComPair

This chassis does not have an IR transmitting LED (as in MG-

sets). Therefore, a "Service" (ComPair) connector is

implemented at the rear side of the set, which is directly

accessible (as in A10-, EM2E-, EM3E and EM5E-sets). In

addition to this, there is also a blinking LED procedure to show

the contents of the error buffer.

When you use ComPair, you have the possibility to activate a

"stepwise start-up" mode. With this mode, you can initiate the

start-up sequence step by step. This also means that in certain

steps, some protections are not activated. This is sometimes

very convenient during repair.

5.8.4

Protections

Activating SDM via the "service pads" will overrule the

processor-controlled protections, but not the hardware

protections. This means, that the A/D-input protections (5 and

8 V) and the I

2

C

"not-acknowledging" info of the feature box

(FBX) and of the Tuner are overruled.

Caution:

When doing this, the service technician must know

what he is doing, as it could lead to damaging the set.

The "ARC"- and/or "BRIDGECOIL" protection are hardly ever

triggered, however:

•

When you suspect the "ARC" protection, look for bad

solder joints and smell. By interrupting resistor 3497, this

protection is disabled (special attention needed!).

•

When you suspect the "BRIDGECOIL" protection, which

can also be due to a too wide picture amplitude, shorten G

and S of the E/W MOSFET 7480. This will disable the

protection. You will now have minimal horizontal amplitude.

Re-align the horizontal amplitude in the SAM menu and

remove the G/S short of TS7480.

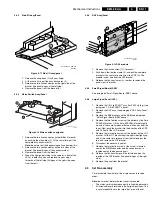

5.8.5

Main Supply

The simplest way is, to replace the components of the Main

Supply with repair kit 3122 785 90310.

More detailed way:

1.

Replace FET 7504 and zener 6505.

2.

Remove the SSB panel.

3.

Short B and E of TS7529, in order to put the Main Supply

in "on"-mode (TS7529 is blocking then).

Caution:

To prevent that R3403 and TS7443 will be

damaged,

first disable the HW-protection of the

deflection circuit.

Therefore short circuit C2642 on the

LSP (diagram A4).

4.

Attach a load of 500 O to V_BAT capacitor C2515 (the

supply can not work without a minimum load).

5.

Use a variac, and slowly increase the V_MAINS. Measure

over sensing resistors R3514//15, if a nice sawtooth

voltage becomes available.

6.

Also measure the V_BAT. This may never 141 V.

If it does, there is something wrong in the feedback circuitry

(e.g. regulator 7506).

Note:

Be careful when measuring on the gate of FET TS7504.

This circuitry is very high ohmic and can easily be damaged

(first connect ground to measuring equipment, than measure

the gate).

5.8.6

Standby Supply

The simplest way is to replace the components of the Standby

Supply with repair kit 3122 785 90460.

RESET

5VCON

8VCON

8V

29

I2C BUS

5

17/39

OUT

HOP

CUTOFF

(from

CRT panel)

START/STOP

START/STOP

COLD

EHT-INFO

HOT

7131

7141

5V

8V

+11D

OTC

POR

POR

7445

106

105

99

104

STANDBY

low 7131/41 closed

high 7131/41 open

220 VAC

STBY

SUPPLY

Vbat

SUP-ENABLE

MAIN

SUPPLY

PROT-

SENSING

LINE DEFL.

(BRIDGECOIL

-PROT)

(ARC-PROT)

FRAME

DEFL

(NON-VFB)

CL16532044_023.eps

140501

1

3

2