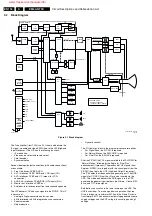

Circuit Descriptions and Abbreviation List

9.

When switching off, the same procedure is followed, but in

reverse order.

9.12.2 Implementation

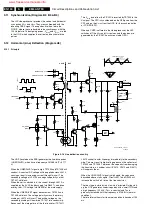

To explain the operation of the line output stage, we use the

following start conditions:

•

C2433 is charged to max. 141 V (V

BAT

)

•

TS7421 is driven into conductivity.

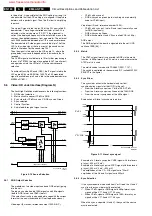

Figure 9-19 Line deflection part 1

•

Period t1-t2: When TS7421 is driven into conductivity, the

capacitor voltage of 141 V will be divided across bridge-coil

L5422 and the deflection coil (connector 1417.) Due to the

chosen inductance values, there will be 100 V across the

deflection coil and 41 V across L5422. The linearly

increasing current in the deflection coil will result in a spot

moving from the center of the picture tube to the right. The

voltage across L5422 will also charge C2421 (41 V - 0.7 V.)

•

Period t2-t3: At the moment the LINEDRIVE signal

becomes high, TS7421 will stop conducting. A voltage will

be induced in the coils, trying to maintain the current. The

current through the line deflection coils continues to flow

through C2425 and C2421 and the current through L5422

continues to flow through C2426 and C2421. The energy

stored in the line deflection coil is passed to C2425, and the

energy of L5422 to C2426. The resonance-frequencies of

these two LC-circuits define the flyback time of the spot

from the right side of the picture tube to the left. On

average, no current flows through C2421 and thus the

voltage across this capacitor remains constant.

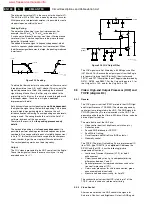

Figure 9-20 Line deflection part 2

•

Period t3-t4: The same as period t2-t3; but now the current

flows in the opposite direction, since the voltage across

C2425 and C2426 is higher than the voltage across C2433

and C2421.

•

Period t4-t5: The coils try to maintain the negative current

and will negatively charge the capacitors. Because of this,

D6422 and D6423 will conduct. The voltage is 100 V

across the deflection coil and 41 V across L5422. Since

both diodes conduct, we may consider the voltage

constant. A linear current flows with the same changing

characteristics as in period t1-t2. The spot now moves from

the extreme left of the picture tube to the center. Before the

current becomes zero, and the spot is located in the center

of the frame, TS7421 reverts into conductivity. A short

negative current will flow. Then the cycle starts again.

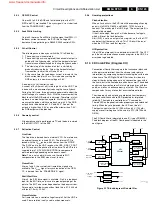

9.12.3 Corrections

Several corrections are necessary to obtain a proper picture.

Linearity Correction

A constant voltage across the horizontal deflection coil should

result in a linearly increasing saw-tooth current. This is not the

case however, as the resistance of the coil is not negligible. In

order to compensate for this, a re-magnetized coil L5421 in

series with the deflection coil is used. This coil ensures that

during time interval t1-t3 the circuit resistance will be higher

than during t4-t5.

L5421 is the linearity coil. To avoid self-oscillation, R3431 and

C2431 are placed parallel to L5421.

See diagram “Line deflection circuitry” item '*1.'

S-correction

Since the sides of the picture are further away from the point of

deflection than the center, a linear saw-tooth current would

result in a non-linear image (the center would be scanned

slower than the sides.)

To solve this, the deflection current for the right side and left

side is reduced.

C2433 is quadratically charged during time interval t1-t2. The

left and right voltage across the deflection coil decreases,

causing the deflection to slow down. In the center, the voltage

increases and the deflection will be faster.

An S-shaped current is superimposed on the saw-tooth

current. This correction is called 'finger-length correction' or 'S-

Correction.'

C2433 is relatively small, and as a result, the saw-tooth current

will generate a parabolic voltage with negative voltage peaks.

The current also results in a parabolic voltage across C2421,

resulting in the finger-length correction, proportionally

increasing with the picture width.

The EW-DRIVE signal will ensure the largest picture width in

the center of the frame. The largest correction is applied here.

The larger the picture width, the higher the deflection current

through C2433.

See diagram “Line deflection circuitry” item '*2.'

E/W-correction

A line written at the upper side or lower side of the screen will

be larger at the screen center when a fixed deflection current is

used. Therefore, the amplitude of the deflection current must

be increased when the spot approaches the screen center.

This is called East/West correction.

The EW drive signal originates in the HOP and is supplied to

TS7480 via OpAmp 7450-B and optocoupler TS7482. The

shape of this signal determines the various geometric

correction parameters:

•

H amplitude

•

EW-parabola

•

EW-corner

•

EW-trapezium

•

Horizontal parallelogram

•

Horizontal bow

TS7480 will charge capacitor C2421 more or less, increasing

the deflection current when reaching the center of the screen.

The moment TS7480 is driven into saturation, C2421 will

discharge during the flyback. As a consequence of this, C2421

must be charged again during the scan via the conduction

diode D6422 (as long as C2421 is not charged to the voltage

across L5422, D6422 will conduct.)

The current in the deflection coil is therefore larger than the

current flowing in L5422 (1-2.) The voltage across the

deflection coil increases, so the picture width increases. When

TS7480 blocks, C2421 will not discharge anymore, and the

voltage across C2421 will remain constant.

The result is that the voltage across the deflection coil is

minimal. The voltage across coil L5422, however, is maximal.

CL 96532156_024.eps

060199

141V

7421

Line defl.

2433

5422

6423

6422

2425

2426

2421

Defl

t2

t3

5430

141V

7421

Line defl.

2433

5422

6423

6422

100V

141V

41V

2425

2426

2421

I

Defl

t2

t1

41V

5430

+

-

I

2420

2420

CL 96532156_025.eps

231299

141V

Line defl.

2433

5422

2425

2426

I Defl

t3 t4

5430

141V

Line defl.

2433

5422

6422

2425

2426

I Defl

t5

t4

5430

100V

141V

41V

+

-

7421

7421

2420

6423

6422

6423

2420

2421

41V

2421

41V

www.freeservicemanuals.info

Summary of Contents for EM5A NTSC

Page 6: ...Direction for Use EN 6 EM5A NTSC 3 3 Direction for Use www freeservicemanuals info ...

Page 7: ...Direction for Use EN 7 EM5A NTSC 3 www freeservicemanuals info ...

Page 8: ...Direction for Use EN 8 EM5A NTSC 3 www freeservicemanuals info ...

Page 9: ...Direction for Use EN 9 EM5A NTSC 3 www freeservicemanuals info ...

Page 10: ...Direction for Use EN 10 EM5A NTSC 3 www freeservicemanuals info ...

Page 11: ...Direction for Use EN 11 EM5A NTSC 3 www freeservicemanuals info ...

Page 12: ...Direction for Use EN 12 EM5A NTSC 3 www freeservicemanuals info ...

Page 13: ...Direction for Use EN 13 EM5A NTSC 3 www freeservicemanuals info ...

Page 14: ...Direction for Use EN 14 EM5A NTSC 3 www freeservicemanuals info ...

Page 15: ...Direction for Use EN 15 EM5A NTSC 3 www freeservicemanuals info ...

Page 16: ...Direction for Use EN 16 EM5A NTSC 3 www freeservicemanuals info ...