Service Modes, Error Codes and Fault Finding

5.

5.6

The Blinking LED Procedure

5.6.1

Introduction

Via this procedure, you can make the contents of the error

buffer visible via the front LED. This is especially useful for fault

finding when there is no picture.

When the SDM is entered, the front LED will show (blink) the

contents of the error-buffer. Error codes > 10 are shown as

follows:

–

A long blink of 750 ms (which is an indication of the decimal

digit.)

–

A pause of 1.5 s.

–

n times a short blink (where n = 1 - 9.)

–

When all the error codes are displayed, the sequence

finishes with a LED blink of 3 s.

–

The sequence starts again.

Example: Error 12 9 6 0 0.

After activation of the SDM, the red front LED will show:

–

1 long blink of 750 ms (which is an indication of the decimal

digit) followed by a pause of 1.5 s.

–

2 short blinks followed by a pause of 3 s.

–

9 short blinks followed by a pause of 3 s.

–

6 short blinks followed by a pause of 3 s.

–

1 long blink of 3 s to finish the sequence.

–

The sequence starts again.

Note: If errors 1, 6 or 18 occur, the LED always gives the last

occurred error even if the set is NOT in service mode.

5.6.2

How to Enter

Use one of the following methods:

•

Enter the SDM (only via shorting solder pads marked

'SDM' on SSB.) The blinking front LED will show the entire

contents of the error buffer (this works in “normal

operation” mode and in “protection” mode.)

•

Transmit the commands 'MUTE' - '062500' - 'OK' with a

normal remote control transmitter. The complete error

buffer is shown. This works only in “protection” mode.

•

Transmit the commands 'MUTE' - '06250x' - 'OK' with a

normal RC (where 'x' is a number between 1 and 5.) When

x= 1 the last detected error is shown, x= 2 the next to last

error, etc.... This works only in “protection” mode.

5.7

Protections

5.7.1

Introduction

The EM5 has only one microprocessor (OTC), which remains

active during “power-off”. This is because the power of the

microprocessor and the attached memory chip set is coming

from the 3V3 supply, which is derived from the 5V Standby

circuitry. So, in both “power-on” and Standby “power-off” mode,

the microprocessor is connected to this power supply.

If a fault situation is detected, an error code will be generated

and, if necessary, the set switches to protection mode. The

protection mode is indicated by the blinking of the red front LED

at a frequency of 3 Hz (or by a coded blinking in special cases.)

However, in some error cases, the microprocessor does not

put the set in the protection mode (this is the case with the -

hardware - loudspeaker protection of the audio amplifier.)

The content of the error buffer can be read via the service menu

(SAM), the blinking LED procedure, or via DST/ComPair.

To get a quick diagnosis, the EM5 has three service modes:

•

The Customer Service Mode (CSM.)

•

The Service Default Mode (SDM.): start-up of the set in a

predefined way.

•

The Service Alignment Mode (SAM.): in this mode, items

of the set can be adjusted via a menu and with the help of

test patterns.

You can enter both SDM and SAM modes via the “service

pads” on the SSB, via a remote control transmitter (DST or

standard RC), or via ComPair. It is not possible to enter the

SAM in “power-off;" the TV has to be in “normal operation”

mode.

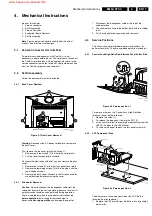

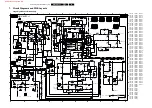

The EM5 “Protection Diagram” shows the structure of the

protection system. See diagram below.

Figure 5-2 Protection diagram

There are several types of protections:

•

I

2

C related protections.

•

OTC related protections (via polling on I/O pins or via

algorithms.)

•

HOP related protections (mainly for deflection items.)

•

Hardware errors that are not sensed by the OTC (for

example, vertical flyback protection, bridge coil protection,

E/W protection, arcing protection.)

All protections are explained below.

5.7.2

I

2

C Related Protections

In normal operation, some registers of the I

2

C controlled ICs

are refreshed every 200 ms. During this sequence, the I

2

C

busses and the I

2

C ICs are checked.

An I

2

C protection will take place if the SDA and SCL lines are

short-circuited to ground, or to each other. An I

2

C error will also

occur, if the power supply of the IC is missing (for example,

FBX_PROT (error 16).)

5.7.3

OTC Related Protections

If a protection is detected at an OTC input, the OTC will start to

scan all protection inputs every 200 ms for 5 times. If the

protection on one of the inputs is still active after 1 s, the

µ

P will

put the set in protection mode. Before the scanning is started,

a so-called “ESD refresh” is carried out. This is done because

the interrupt on one of the inputs is possibly caused either by a

flash or by ESD. Since a flash or ESD can influence IC settings,

the HOP, HIP, MSP, PICNIC, NVM, and Tuner are initialized

XPR (43)

7301

7001

FLS (5)

HFB-XRAY-PROT

HOP

+8V SENSE (105)

+5V SENSE (106)

OTC

EHT-info

HFB

+5V_CON

+8V_CON

FLASH

DETECT

I2C

I2C PROTECTIONS

HIP

HOP

PICNIC

TUNER

NVM

DNR

MSP

TOPIC

I2C

I2C

PICNIC 3V3

TUNER

3D COMB

*

FBX

PROTECTION

CL 26532041_081.eps

190402

LEVEL

DETECT

(*

NTSC SETS ONLY

)

www.freeservicemanuals.info

Summary of Contents for EM5A NTSC

Page 6: ...Direction for Use EN 6 EM5A NTSC 3 3 Direction for Use www freeservicemanuals info ...

Page 7: ...Direction for Use EN 7 EM5A NTSC 3 www freeservicemanuals info ...

Page 8: ...Direction for Use EN 8 EM5A NTSC 3 www freeservicemanuals info ...

Page 9: ...Direction for Use EN 9 EM5A NTSC 3 www freeservicemanuals info ...

Page 10: ...Direction for Use EN 10 EM5A NTSC 3 www freeservicemanuals info ...

Page 11: ...Direction for Use EN 11 EM5A NTSC 3 www freeservicemanuals info ...

Page 12: ...Direction for Use EN 12 EM5A NTSC 3 www freeservicemanuals info ...

Page 13: ...Direction for Use EN 13 EM5A NTSC 3 www freeservicemanuals info ...

Page 14: ...Direction for Use EN 14 EM5A NTSC 3 www freeservicemanuals info ...

Page 15: ...Direction for Use EN 15 EM5A NTSC 3 www freeservicemanuals info ...

Page 16: ...Direction for Use EN 16 EM5A NTSC 3 www freeservicemanuals info ...