Service Modes, Error Codes and Fault Finding

EN 28

5.

again, to ensure normal picture and sound conditions of the

set.

8 V and 5 V protection: The microprocessor senses the

presence of the 8 V and 5 V (via the '+5V_CON' and

'+8V_CON' lines.) If one (or both) of these voltages is (are) not

present, an error code is stored in the error buffer of the NVM,

and the set is put in protection mode.

5.7.4

HOP Related Protections

Every 200 ms, the status register of the HOP is read by the

OTC (via the I

2

C bus.) If a protection signal is detected on one

of the inputs of the HOP, the relevant error bit in the HOP

register is set to “high”. If this error bit is still “high” after 1 s, the

OTC will store the error code in the error buffer of the NVM and,

depending on the relevancy of the error bit, the set may or may

not go into protection mode.

The following protections are implemented:

•

HFB (Horizontal Flyback): If the horizontal flyback is not

present, this is detected via the HOP (HFB_X-

RAY_PROT.) One status bit is set to “high”. The error code

is stored in the error buffer and the set will go into

protection mode.

•

XPR (X-ray protection): If the HFB pulses are too low

(level detection), the HOP will detect this via the XPR-bit.

The error will be logged in the error buffer and the set will

go into protection mode.

Note: Both errors will be logged as HFB-failure.

5.7.5

Hardware Related Protections

Due to the architecture (“hot” deflection), some protections

cannot be sensed by the microprocessor. Three of these

protections will lead to a protection on set level (“power-off”

mode and blinking LED), while another will only lead to a circuit

protection.

TV set Protection

The following fault conditions will lead to a “complete” set

protection:

•

BRIDGECOIL protection: This is sensed via the 'EW'

signal going to the base of TS7652 (via R3495 and D6499.)

In a normal situation, the voltage on C2498 (diagram A4) is

high and TS7652 is conducting. When bridge coil 5422

(diagram A3) is short circuited, the voltage on C2498

changes to low, which will block TS7652. In this case,

TS7641 will also block and the voltage on 2642 will rise

until TS7443 is forced in conduction. The 'SUP-ENABLE'

signal (-20 V in normal operating conditions) is now shorted

to ground level, which will force the Main Power Supply to

“power-off” mode.

•

ARC protection: If there are “open” connections (for

example, bad solder joints) in the high-energy deflection

circuitry, this can lead to damaging effects (fire.) For that

reason, the E/W current is sensed (via 3479/3480.) If this

current becomes too high, the “thyristor” circuit (TS7653

and TS7654) is triggered. TS7442 is switched “on” and

TS7443 is forced into conduction. The 'SUP-ENABLE'

signal is now shorted to ground level, which will force the

Main Power Supply to “power-off” mode.

•

NON_VFB (No vertical Flyback) protection: If the frame

stage generates no pulses, TS7641 will block. TS7443 is

now switched “on”, which will lead to “power-off” mode. So,

in normal operation conditions, TS7641 and TS7652 are

conducting, while TS7443 is blocked.

Circuit Protection

The following fault condition will lead to a “partial” set

protection:

•

PROT1 (DC) protection: When a DC voltage (positive or

negative) is sensed on one of the loudspeaker outputs, the

protection circuit (TS7704, 7705, 7706 and 7707 in

diagram A6) will put IC7700 in Standby mode (via tri-state

input pin 6.) For more details, see the 'Circuit Descriptions

and Abbreviation List' section.

5.8

Repair tips

5.8.1

Miscellaneous

The relay you hear when you switch the set “on”, is from the

degaussing circuitry. It is not used for switching the Power

Supply (as was the case in the MG chassis.)

Always switch the set completely 'off' (disconnect the AC

power cord) when you want to remove the SSB module,

otherwise a lot of components can be damaged (because there

always is a standby voltage present on the SIMM connector.)

Take care not to touch the “hot” heatsink while disconnecting

the SSB, despite the fact that the power cable is disconnected.

A rest-voltage can remain on the heatsink for a short while.

Advice: When you remove the SSB, disconnect the power

cable.

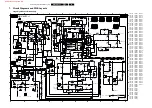

Do not try to measure on the SSB side, which is facing the

“hot” heatsink. This is dangerous. Most service test points are

on the “tuner” side and are indicated by the “service” printing.

Where the circuitry was too “crowded” for this printing, you can

find the correct location on the “test point overviews” in this

manual.

A very large portion of the LSP is “hot”, such as:

–

The primary part of the Standby Supply.

–

The whole Main supply (except for the secondary Audio

supply.)

–

The complete deflection circuitry (note that the deflection

coil is hot!)

5.8.2

Start-up Sequence

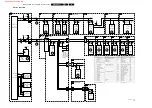

Figure 5-3 Start-up circuitry

The start up sequence differs from other sets (for example, MG

sets or EM2E sets; but it is the same as the EM3E set):

1.

When the set is switched “on”, the 5 V and 8 V lines

(‘+5V_CON’ and ‘+8V_CON’) of the standby power supply

are activated.

2.

After the OTC senses these voltages, the

µ

P will address

the HOP via the I

2

C-bus, to start the drive [1].

RESET

5VCON

8VCON

8V

29

I2C BUS

5

17/39

OUT

HOP

CUTOFF

(from

CRT panel)

START/STOP

START/STOP

COLD

EHT-INFO

HOT

7131

7141

5V

8V

+11D

OTC

POR

POR

7445

106

105

99

104

STANDBY

low 7131/41 closed

high 7131/41 open

220 VAC

STBY

SUPPLY

Vbat

SUP-ENABLE

MAIN

SUPPLY

PROT-

SENSING

LINE DEFL.

(BRIDGECOIL

-PROT)

(ARC-PROT)

FRAME

DEFL

(NON-VFB)

CL16532044_023.eps

140501

1

3

2

www.freeservicemanuals.info

Summary of Contents for EM5A NTSC

Page 6: ...Direction for Use EN 6 EM5A NTSC 3 3 Direction for Use www freeservicemanuals info ...

Page 7: ...Direction for Use EN 7 EM5A NTSC 3 www freeservicemanuals info ...

Page 8: ...Direction for Use EN 8 EM5A NTSC 3 www freeservicemanuals info ...

Page 9: ...Direction for Use EN 9 EM5A NTSC 3 www freeservicemanuals info ...

Page 10: ...Direction for Use EN 10 EM5A NTSC 3 www freeservicemanuals info ...

Page 11: ...Direction for Use EN 11 EM5A NTSC 3 www freeservicemanuals info ...

Page 12: ...Direction for Use EN 12 EM5A NTSC 3 www freeservicemanuals info ...

Page 13: ...Direction for Use EN 13 EM5A NTSC 3 www freeservicemanuals info ...

Page 14: ...Direction for Use EN 14 EM5A NTSC 3 www freeservicemanuals info ...

Page 15: ...Direction for Use EN 15 EM5A NTSC 3 www freeservicemanuals info ...

Page 16: ...Direction for Use EN 16 EM5A NTSC 3 www freeservicemanuals info ...