HR7764

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

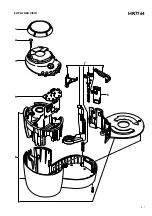

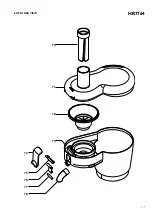

- The blender coupling on the motor shaft has been provided

with a customary left-handed thread.

The drive coupling (item 10) can be detached by means of

a hammer and a screwdriver. Strike the screwdriver with a

short sharp blow and remove the drive coupling, or block

the acc. drive wheel (item 17) and thereby the rotor shaft,

by sticking a pin through the hole (5 mm dia. – marked

with an arrow) in the bottom plate.

- The assembly of the accessories depends on the national

version.

REPAIR INSTRUCTIONS

- For specific versions, the component configuration may

differ from the one shown on the exploded view. However,

the actual components can be distinguished by their code

numbers.

- Make sure that all functions, including the safety devices,

are working correctly after you have completed the repair.

Automatic resettable cut-out

(part of item 11)

To prevent damage due to overheating, the appliance has been

equipped with an automatic cut-out system.

This system will automatically cut off the power supply when

the appliance overheats.

If the appliance suddenly stops running:

- Unplug the appliance

- Switch off the appliance

- Let the appliance cool down for 15 minutes

- Plug the appliance in again

- Switch the appliance on again

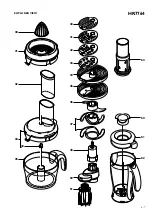

Safety lock

(item 7)

Place the lid on the bowl in the right position. The appliance

will only function if the line on the applinace is directly

opposite the mark on the lid of the food processor bowl and

the same holds for the other accessoires. The built-in safety lock

will now be deblocked and you can turn the appliance on.

Note that if both the blender jar and the bowl have been

correctly mounted, only the blender will function.

Important:

If the appliance is used without the blender jar, the appliance

will not function, when the blender coupling (item 10) has not

been protected by the blender cover (item 1).

Note:

The blender cover can only be removed, when the bowl

including the bowl lid is not mounted on the foodprocessor.

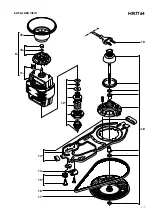

How to set the belt tension:

Step 1: Give 30 N pretension force on the adjusting plate to

minimise the distances between the belt and the belt

wheels

Step 2: Reduce the tension force from 30 N down to 10 N

which is the required belt drive force for the appliance.

Step 3: Fix the adjusting screw on the adjusting plate when the

tension force reaches the value of 10 N (after coming

down from 30 N!)

OPTIONAL (accessories)

- No specific issues

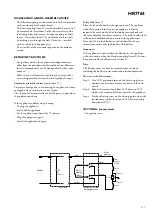

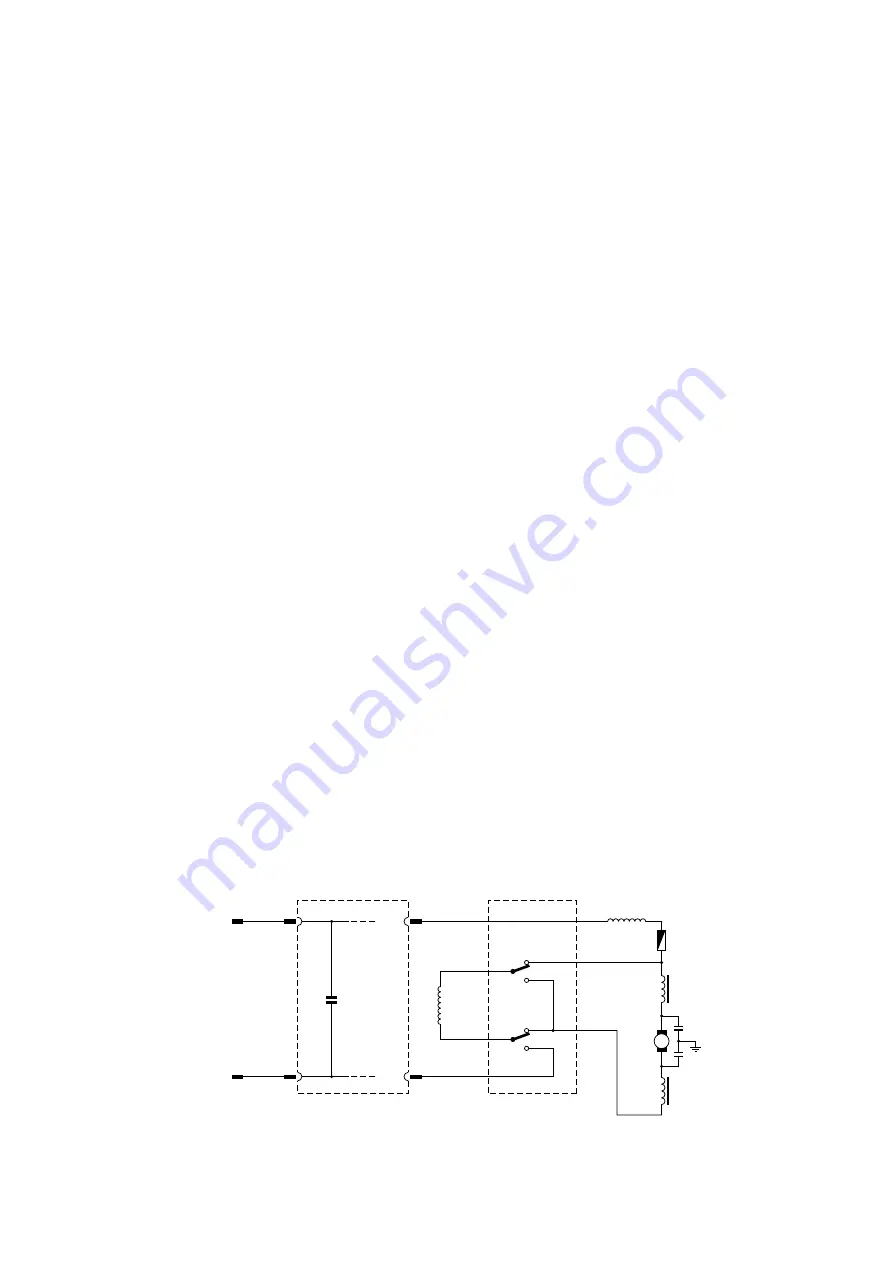

MAINS

C1

Change-over switch

in braking position

Motor

winding

Motor

winding

Main PCB

brown

red

yellow

white

red

S1

S2

black

yellow

Rotor

Y-

capacitor

X2

capacitor

TCO

Thermal

Cut Off

Y-

capacitor

Choke

Choke

2-7