Safety Instructions, Warnings, and Notes

EN 5

FHP PDP

2.

2.

Safety Instructions, Warnings, and Notes

2.1

Safety Instructions

h

It is not allowed to operate the FTV-set without glass plate. One

function of this glass plate is to absorb Infrared Radiation.

Without this glass plate the level of Infrared Radiation produced

by the plasma display could damage your eyes.

1.

Safety regulations require that during a repair:

–

the set should be connected to the mains via an

isolating transformer (in this particular case a

transformer of

≥

800 VA).

–

safety components, indicated by the symbol

h

,

should be replaced by components identical to the

original ones.

2.

Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

–

Note: The wire trees should be routed correctly and

fixed with the mounted cable clamps.

–

The insulation of the mains lead should be checked for

external damage.

–

The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets that have a mains isolated power supply). This

check can be done as follows:

•

unplug the mains cord and connect a wire between

the two pins of the mains plug;

•

set the mains switch to the on position (keep the

mains cord unplugged!);

•

measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 M

Ω

and 12 M

Ω

;

•

switch off the TV and remove the wire between the

two pins of the mains plug.

–

The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2

Warnings

ESD

w

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD

w

). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass of

the set by a wristband with resistance. Keep components and

tools also at this same potential.

1.

Available ESD protection equipment:

–

complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

–

wristband tester 4822 344 13999

2.

Never replace modules or other components while the unit

is switched on.

3.

When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3

Notes

1.

A glass plate is positioned before the plasma display. This

glass plate can be cleaned with a slightly humid cloth. If

due to circumstances there is some dirt between the glass

plate and the plasma display panel it is recommended to do

some maintenance by a qualified service employee only.

2.

Never disconnect the power display cable when the set is

operating

3.

With DST no failures (error-codes) can be red, when the

set is in Service-mode.

4.

If DST reacts with "error 2", there is no communication

between the TV and the DST. Note that the IR-transmitter

LED is positioned at the right side of IR-receiver eye of the

E-box. Take into account that receiver-LED on DST is

positioned not in the middle but at the left side. Point

corresponding LEDs to each other. In case the amount of

Infrared produced by the screen pollutes the

communication, the set can be set in Stand-by-mode. Then

still the error-messages can be retrieved.

2.3.1

Notes on Safe Handling of the Plasma Display

Notes to Follow During Service

•

The work procedures shown with the Note indication are

important for ensuring the safety of the product and the

servicing work. Be sure to follow these instructions.

•

Before starting the work, secure a sufficient working space.

•

At all times other than when adjusting and checking the

product, be sure to turn OFF the main POWER switch and

disconnect the power cable from the power supply of the

display during servicing.

•

To prevent electric shock and breakage of PC board, start

the servicing work at least 30 seconds after the main power

has been turned off. Especially when installing and

removing the power supply PC board and the SUS PC

board in which high voltages are applied, start servicing at

least 2 minutes after the main power has been turned off.

•

While the main power is on, do not touch any parts or

circuits other than the ones specified. The high voltage

power supply block within the PDP module has a floating

ground. If any connection other than the one specified is

made between the measuring equipment and the high

voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

•

When installing the PDP module in, and removing it from

the packing carton, be sure to have at least two persons

perform the work white being careful to ensure that the

flexible printed-circuit cable of the PDP module does not

get caught by the packing carton.

•

When the surface of the panel comes into contact with the

cushioning materials, be sure to confirm that there is no

foreign matter on top of the cushioning materials before the

surface of the panel comes into contact with the cushioning

materials. Failure to observe this precaution may result in,

the surface of the panel being scratched by foreign matter.

•

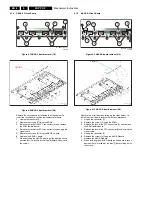

When handling the circuit PC board, be sure to remove

static electricity from your body before handling the circuit

PC board.

•

Be sure to handle the circuit PC board by holding the large

parts as the heat sink or transformer. Failure to observe

this precaution may result in the occurrence of an

abnormality in the soldered areas.

•

Do not stack the circuit PC boards. Failure to observe this

precaution may result in problems resulting from scratches

on the parts, the deformation of parts, and short-circuits

due to residual electric charge.

•

Routing of the wires and fixing them in position must be

done in accordance with the original routing and fixing

configuration when servicing is completed. All the wires are

routed far away from the areas that become hot (such as

the heat sink). These wires are fixed in position with the

wire clamps so that the wires do not move, thereby

ensuring that they are not damaged and their materials do

not deteriorate over long periods of time. Therefore, route

the cables and fix the cables to the original position and

states using the wire clamps.

•

Perform a safety check when servicing is completed. Verify

that the peripherals of the serviced points have not

undergone any deterioration during servicing. Also verify

that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in

accordance with the original setup