F — MAINTENANCE NOTES

1.

Removal of backplate

Remove two screws from the top of the backplate which may

then be hinged out from the bottom and lifted away.

2.

Access to the convergence panel

The convergence panel is located on the front of the receiver in the

top right-hand corner, behind the upper moulded grille. To remove

the grille, lever out the name plate by pressing it in at one end (see

Fig. 2) then withdraw retaining screw A and lift out the grille.

Unhook the assembly containing

CI701

and R1702 and

remove

the four securing nuts from the

corners

cf the shield

which may

then be withdrawn. The degaussing coils may be released from

the

shield by bending back the retaining tabs. Fit the new coils

to

the

shield and clamp them by bending

over

each tab, then solder the

coil leads to the respective tag strip.

When

reassembling the shield,

ensure that spacers, washers and nuts are assembled in the correct

order (see Fig. 3).

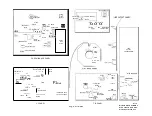

Fig. 3. Assembly of C.R.T. and shield

SC 3809

Fig. 2. Removing convergence cover

3 .

T o l o w e r c h a s s i s

Remove two self-tapping screws from the top of the chassis, then

swing back the chassis to the extent of the securing lead.

4 .

Removal of the tuner assembly

Unplug the I.F. lead and two fly-leads connecting the tuner to the

receiver. Loosen three screws securing the aerial panel to the

mounting bracket on the chassis and detach the panel. Release the

single fixing screw from the tuner mounting bracket after which the

tuner, complete with leads, may be withdrawn from the cabinet.

5 .

Removal of the control panel

Pull off three control knobs and release four screws from the rear

of the control panel. The panel (still attached by its connecting

leads) may now be withdrawn from the cabinet.

6 .

Removal of the convergence unit

Remove four 4BA nuts and shake-proof washers from the corners

of the convergence control panel. The panel (still attached by its

leads) may now be withdrawn from the cabinet.

7 .

Replacement of degaussing coils L1723/4

Remove the main chassis, tuner assembly, control panel and con-

vergence unit together with the convergence yoke, deflection coils

and blue lateral unit. Lay the cabinet face downwards, supported

at each corner to prevent the C.R.T. taking the weight of the cabinet.

8.

Removal of the C.R.T.

WARNING

Extreme care must be taken when handling the C.R.T. and all safety

precautions must be taken.

Carry out the procedure as stated above for degaussing coil re-

placement. When the metal shield has been withdrawn, the C.R.T.

may be lifted away from the cabinet.

Note.

When the chassis, deflection coils, etc., have been re-assem-

bled, the receiver should be allowed to warm up for at least

20 minutes before any convergence or chroma. adjustments are

attempted. The blue lateral shift assembly should be fitted on the

C.R.T. neck with its shift magnets horizontal, and the lead tags

pointing to the base of the tube. The whole assembly must be

mounted as close to the convergence yoke as possible, allowi e -

sufficient space for the purity rings to be turned.

G — L.O.P.T. ASSEMBLY

Before replacing any valves, components, etc., in the L.O.P.T.

assembly, the anode cap of the C.R.T. should be disconnected and

short circuited to chassis to remove any residual charge remaining

on the tube.

1.

PL509 and PY500 removal

Unclip the wire cage top cover, pull off the top cap connections

then remove the valves.

2.

E Y 5 1 r e m o v a l

Unclip the wire

cage top cover and remove the lower side plate

(2 screws at the back of the plate). Unsolder the three leads from

the valve to the tag panel, then fit a new valve. When replacing the

side plate, ensure that the focus panel

lug

seats correctly in the slot

in the metal side plate.

3.

P D 5 0 0 r e m o v a l

Remove the main metal side plate (6 screws). Loosen the four

screws securing the top plate together with the valve base, and

slide the plate upwards to allow the valve to be withdrawn from

its holder.

121

•

MOUNTING BRACKET FZR

DEGAUSSING SHIELD

12 mm

122

123

119'

CRT. FIXING

BRACKET

117

- - - - - -

C A B I N E T

FRONT

/

115

120

/

1

,

21.

SD 3933

Page Six

Summary of Contents for G22K511

Page 3: ...G22K511 G25K512 Page Two ...

Page 12: ...Page Ten ...

Page 14: ...Page Eleven ...

Page 19: ...Page Fifteen ...