PARTS LIST + DISASSEMBLY ADVICE STAND

Pos

Service Nummer

Tray rubber foot for fi xation

Complete tray

Safety cap for boiler

Filling hole gasket for alu boiler

Superior stand printed

22

23

24

25

26

9965 000 08193

9965 000 08194

9965 000 08195

9965 000 01782

9965 000 08252

27

28

29

30

31

32

33

34

35

36

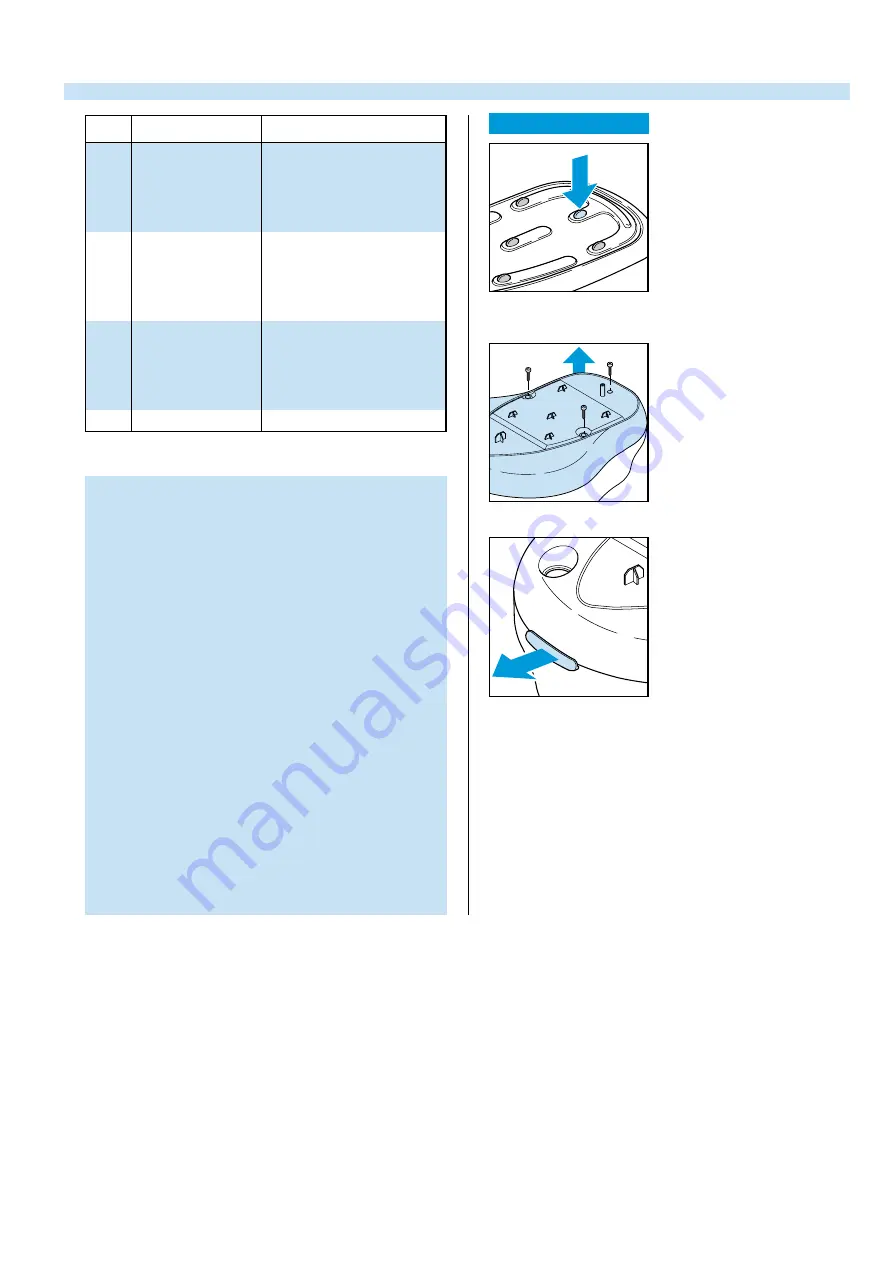

OPEN THE STAND

pressure fi xation rubber through

the tray

E

E

E

remove SCREW E (3 x)

remove LOCKED INSERT 29

NOTE:

OPEN NOW THE STAND.

DON’T WORRY IF THE SNAPS AT THE SIDE WILL BE

BROKEN.

THEY ARE ONLY FOR THE ASSEMBLY.

THE STAND REMAINS CLOSE WITHOUT THESE SNAPS.

ADJUSTMENT AND CONTROLS

– To avoid leakage of the sealings and damage to

the components in and on the boiler, NEVER clean

the boiler with vinegar, a descaling agent or other

chemicals.

– The boiler doesn’t contain serviceable parts.

Never disassemble the boiler body and /or

components on and in the boiler.

– ALWAYS REPLACE THE BOILER ( 28 ) WHEN:

*

the mechanical safety valve ( 24 ) has been

activated.

*

the boiler thermostat or hand - resettable safety

thermostat are open, because the boiler has

been subjected to too high temperatures.

*

the electrovalve ( 33 ) fails or the sieve is soiled

with scale.

– After the product has been repaired, it should

function properly and has to meet the safety

requirements as laid down and offi cially established

at this moment.

Description

4822 462 71999

9965 000 08240

9965 000 08201

9965 000 08202

9965 000 01790

Boiler rubber feet

Complete boiler

Locket insert

Inferior stand

Filter

9965 000 08203

4822 218 11561

9965 000 08241

9965 000 01900

9965 000 01902

Main switch

Electrovalve

Steam dial

Sream regulator

Steam ready light

37

9965 000 08246

Funnel