GC6360

2-6

DISASSEMBLY ADVICE - IRON

THERMOSTAT DIAL 1

RATTLE SPRING 13

BACKPLATE 2

Disassemble

DIAL 1

Remove

Screw A

Remove

Connection

Remove

Hose

INLAY (SOS) 3

SOS KNOB 14

TRIGGER 12

IRON LAMP ASSY 4

MICRO SWITCH 5

REPAIR INSTRUCTIONS

- For disassembly, you will need a Torx screwdriver: 362 TR T20 x 100

OPTIONAL (accessories)

- No specific issues

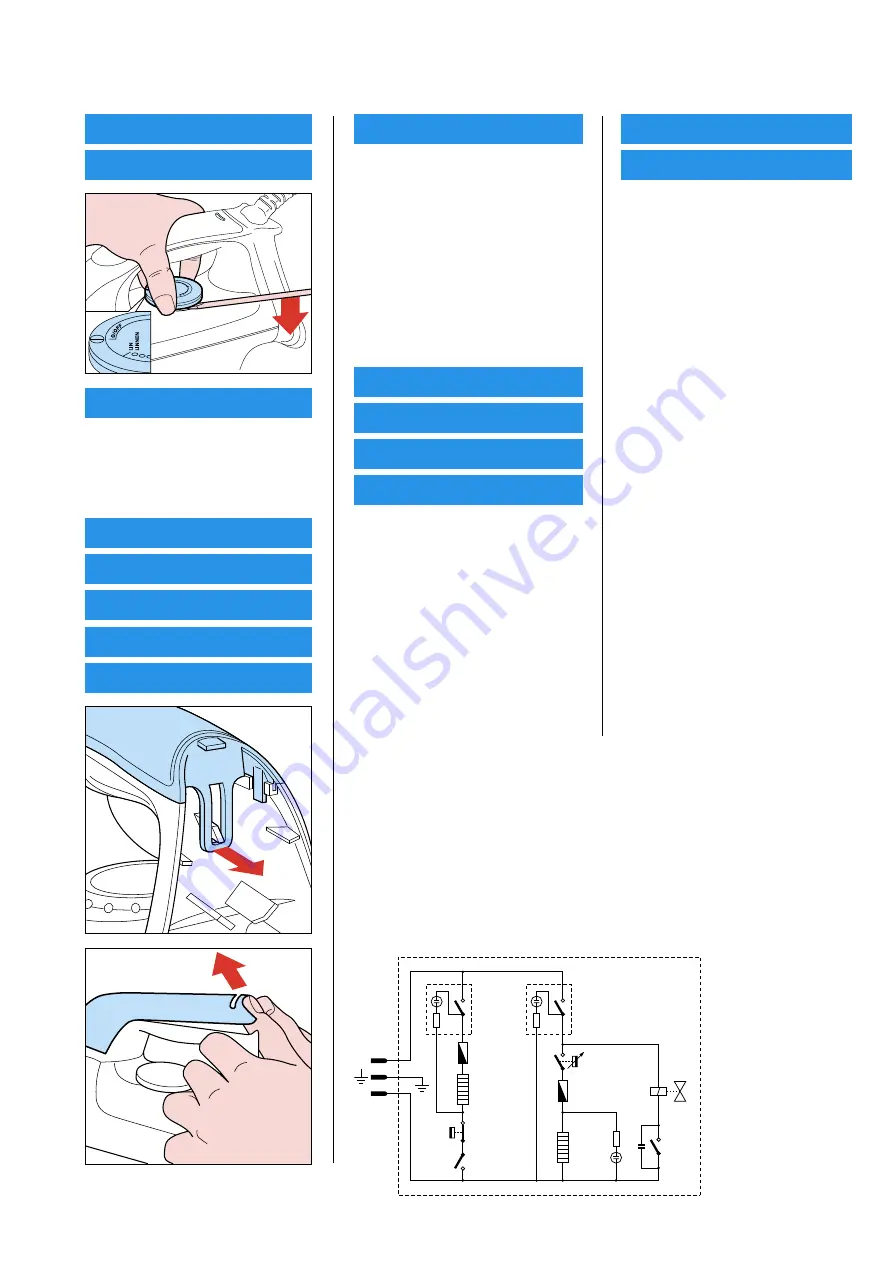

Electrical Diagram

Boiler

Heating

Element

Boiler

Switch

Iron

Switch

Thermo-

fuse

Thermofuse

Iron

Heating

Element

T (100˚C)

Thermostat

Thermostat

Micro-

switch

Pressostat

Electro-

valve

L

N

C

HANDLE PRINTED 6

Disassemble

DIAL 1

Remove

Screw A

Remove

Connection

Remove

Hose

Disassemble

BACKPLATE 2

Disassemble

INLAY (SOS) 3

SOS KNOB 14

IRON LAMP ASSY 4

MICRO SWITCH 5

Remove

Screws B (3 x)

HOSE-CORD ASSY 7

SWIVEL 8

STEAM DEVIAOR 15

THERMOSTAT BUSH 9

Disassemble

DIAL 1

Remove

Screw A

Remove

Connection

Remove

Hose

Disassemble

BACKPLATE 2

Disassemble

INLAY (SOS) 3

SOS KNOB 14

IRON LAMP ASSY 4

MICRO SWITCH 5

Remove

Screws B (3 x)

Disassemble

HANDLE PRINTED 6

IRON COVER SPRAYED 10

SOLEPLATE ASSY 11

Disassemble

DIAL 1

Remove

Screw A

Remove

Connection

Remove

Hose

Disassemble

BACKPLATE 2

Disassemble

INLAY (SOS) 3

SOS KNOB 14

IRON LAMP ASSY 4

MICRO SWITCH 5

Remove

Screws B (3 x)

Disassemble

HANDLE PRINTED 6

Disassemble

HOSE-CORD ASSY 7

SWIVEL 8

STEAM DEVIATOR 15

THERMOSTAT

BUSH

9

Remove

Screws C (3 x)