GC6360

4-6

DISASSEMBLY ADVICE & PARTS LIST - BOILER STAND

HEAT INSULATION PLATE 22

TOP COVER 23

BOILER MOUNTED ASSY 31

Remove

screw G (5x)

Disassemble

TOP COVER 23

Straighten ear locks of Heat Insulation Plate

Disassemble

HEAT INSULATION

PLATE

22

FACE PLATE 26

LIGHT SWITCH HOLDER 29

LIGHT SWITCH 30

STEAM REGULATOR 33

Remove

screw G (5x)

Disassemble

TOP COVER 23

Remove

screw E (4x)

Disassemble

FACE PLATE 26

Remove

screw F (4x)

Disassemble

LIGHT SWITCH

HOLDER

29

Remove

screw H (2x)

Disassemble

STEAM REGULATOR 33

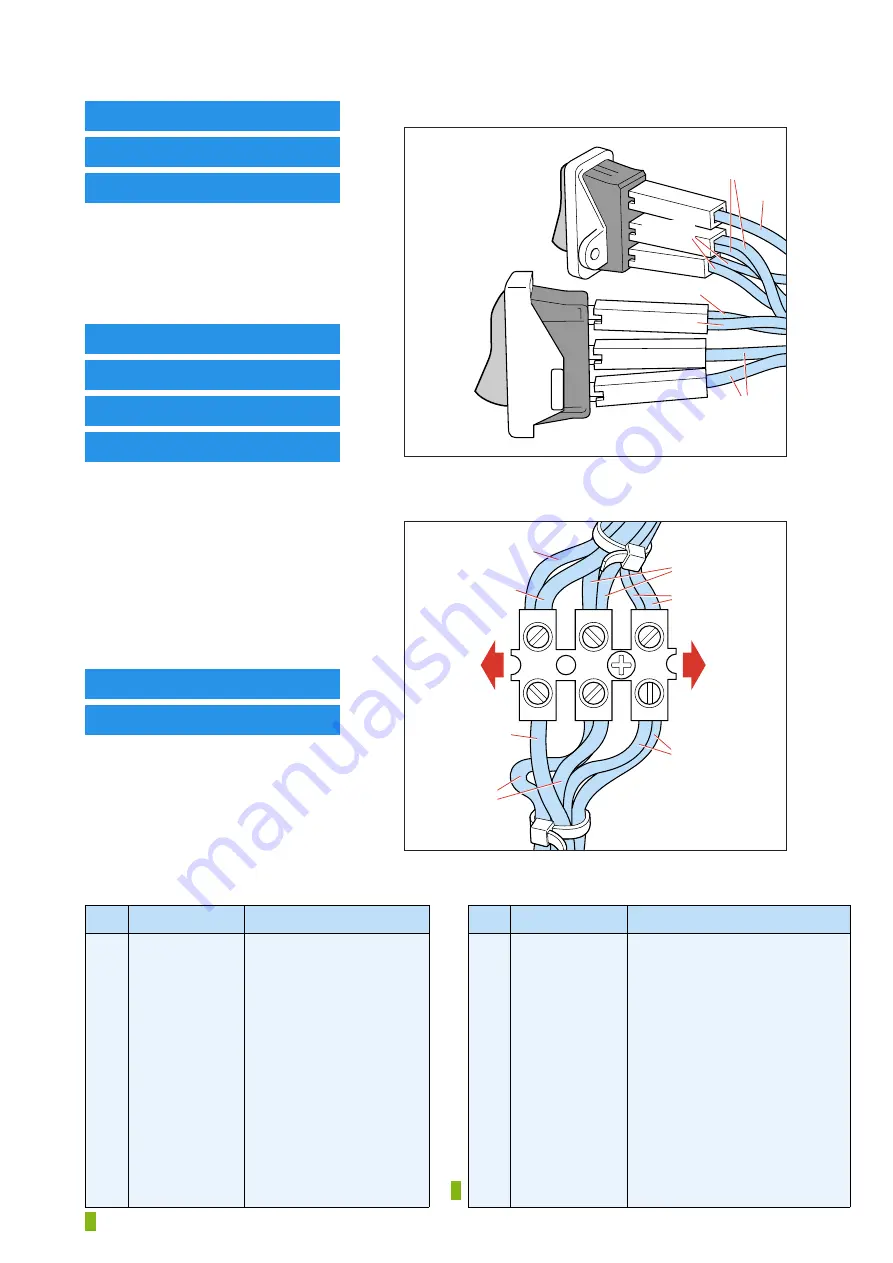

HOSE-CORD ASSY 40

POWER CORD 41

Remove

screw G (5x)

Disassemble

TOP COVER 23

Remove

screw J (3x)

Disassemble

STAND CORD

CLAMP

35

Connections on LIGHT SWITCH 30

Blue

Yellow

Iron

switch

Boiler

switch

Blue

Yellow/

Green

Brown

Brown

Connections on BIGTERMINAL BLOCK 34

BOILER

side

FACE

PLATE

side

Blue

Yellow

Brown

Brown

Blue

Yellow/

Green

Yellow/

Green

Note:

When replacing HOSE-CORD ASSY 40, please refer to IMPORTANT directives in the REPAIR INSTRUCTIONS on page 6.

Pos

Service code

Description

20

21

22

23

24

25

26

27

28

29

30

31

32

4239 022 57780

4239 022 57790

4239 022 55560

4239 022 57800

4239 022 57810

4239 022 55660

4239 022 57820

4239 022 57830

4239 022 57840

4239 022 55600

4239 022 55840

4239 022 55720

4239 022 55700

Silicon cap A

Silicon cap B

Heat insulation plate

Top cover

Safety cap assy (Leak pressure

valve + Relief valve cap)

Filling hole gasket

Face plate

Steam dial

Steam dial ring

Light switch holder

Light switch

Boiler mounted assy

Silicon hose (L = 140 mm)

Pos

Service code

Description

33

34

35

36

37

38

39

41

42

43

44

45

46

47

4239 022 55710

4239 022 55850

4239 022 55790

4239 022 55540

4239 022 57850

4239 022 57320

4239 022 55680

4239 022 57340

4239 022 55670

4239 022 57860

4239 022 55860

4239 022 55610

4239 022 55620

4239 022 58590

Steam regulator

Big terminal block

Stand cord clamp

Boiler foot

Bottom cover

Guard jacket

Stand foot

Power cord - EU

Cable tie

Stand assy - GC6360

Neon lamp

Neon lamp cover

Neon lamp holder

Safety valve sealing ring

= changed