GC7220

5-7

TRAY RUBBER CAP 30

TRAY ASSY 33

DOOR ASSY 35

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw G

Disassemble

DOOR ASSY 35

FRONT PANEL PRINTED 37

POWER BOARD 43

LIGHT SWITCH 44

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw H1, H2

Disassemble

FRONT PANEL 37

Disassemble

LIGHT SWITCH 44

Disassemble

POWER BOARD 43

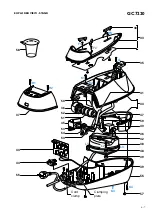

DISASSEMBLY ADVICE - STAND

WATER TANK ASSY 34

HOSE CORD CAP 36

BOILER ASSY 38

BRAIDED RUBBER HOSE -

BOILER 41

PUMP ASSY 45

INLET TUBE - PUMP 46

DE-AIR TUBE 47

RINSE RUBBER COUPLING 50

RINSE BUSH 51

RINSE CAP ASSY 52

Remove

TRAY RUBBER CAP 30 (3x)

Remove

Screw F1, F2, F3

Disassemble

TRAY ASSY 33

Remove

Screw H1, H2

Disassemble

FRONT PANEL 37

Disassemble

HOSE CORD CAP 36

Disassemble

RINSE CAP ASSY 52

Disassemble

RINSE BUSH 51

Disassemble

RINSE RUBBER COUPLING 50

Remove

Screws K1, K2, K3, K4

Disconnect

INLET TUBE - PUMP 46

Disconnect

DE-AIR TUBE 47

Disassemble

WATER TANK ASSY 34

Disassemble

BRAIDED RUBBER HOSE - BOILER 41

Disassemble

PUMP ASSY 45

Remove

Torx screws L1, L2, L3

Disassemble

TOP SPACER 48

Disassemble

BOILER ASSY 38

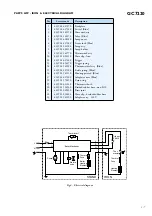

PARTS LIST - STAND

Pos

Service code

Description

30

33

34

35

36

37

38

39

40

41

42

43

44

45

46

4239 015 56780

4239 021 39670

4239 021 42140

4239 021 40140

4239 026 26410

4239 021 41000

4239 021 39530

4239 017 10420

4239 017 09890

4239 015 56930

4239 010 10260

4239 021 40330

4239 017 10510

4239 021 39720

4239 015 56860

Tray rubber cap (Blue)

Tray assy

Water tank assy (Blue)

Door assy (Blue)

Hose cord cap (Blue)

Front panel printed

Boiler assy Low End

Thermistor

Electrovalve

Braided rubber hose - boiler

Inox clamp - boiler

Power board

Light switch

Pump assy Low End

Inlet tube - pump

Pos

Service code

Description

47

48

49

50

51

52

53

54

55

56

57

58

59

4239 015 56870

4239 026 26120

4239 026 26110

4239 015 56760

4239 026 26130

4239 021 39570

4239 010 10600

4239 015 56880

4239 000 10100

4239 026 26080

4239 015 52340

4239 026 05990

4239 010 10610

De-air tube

Top spacer

Bottom spacer

Rinse rubber coupling

Rinse bush

Rinse cap assy (Blue)

Inox clamp - pump

Braided rubber hose - pump

Cordset EU

Stand bottom

Bung

Filling cup

Hose clip - pump