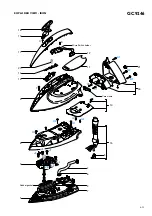

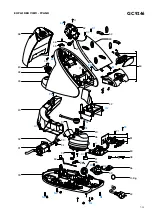

GC9246

6-12

PARTS LIST - STAND

Pos

Service code

Description

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

58

59

60

6

3

4239 021

61591

4239 021 6160

1

4239 026 42081

4239 015 59201

4239 010 10261

4239 026 32181

4239 021 61611

2

922 021 98946

4239 021 61812

4239 021

76221

4239 026 31641

4239 026 42581

4239 026

42591

4239 021

61621

4239 000

11581

4239 026

52621

4239 026

52631

4239 014 54982

4239 021

72361

4239 026

52751

4239 021

76611

4239 021

75691

4239 021

75711

4239 026

42742

4239 015

60231

4239 015

60241

4239 021

75721

4239 021

75731

4239 021 6172

3

4239 021

77331

4239 015 60221

Stand bottom assy

Pump assy

De-air valve

Braided rubber hose boiler

Inox clamp

Spacer Bottom molded

Boiler assy

Electrovalve

Thermistor assy Boiler

Rinse Housing printed

Spacer top molded

Boiler support bracket molded

Power cord storage molded

Hose cord storage compartment assy

Cord set

EU

Stand top molded

Tank Catch molded

Tank Catch Spring

Inlet coupling plate welded

De-air coupling molded

Display cover printed assy

Button panel assy

Front Bracket assy

Tray molded

Tray rubber cap

Rinse Rubber Bush

Rinse cap assy

Water tank printed assy

Hall sensor PCBA assy

Power Board PCB assy

Tube seal

= changed