HD5720/30

6-23

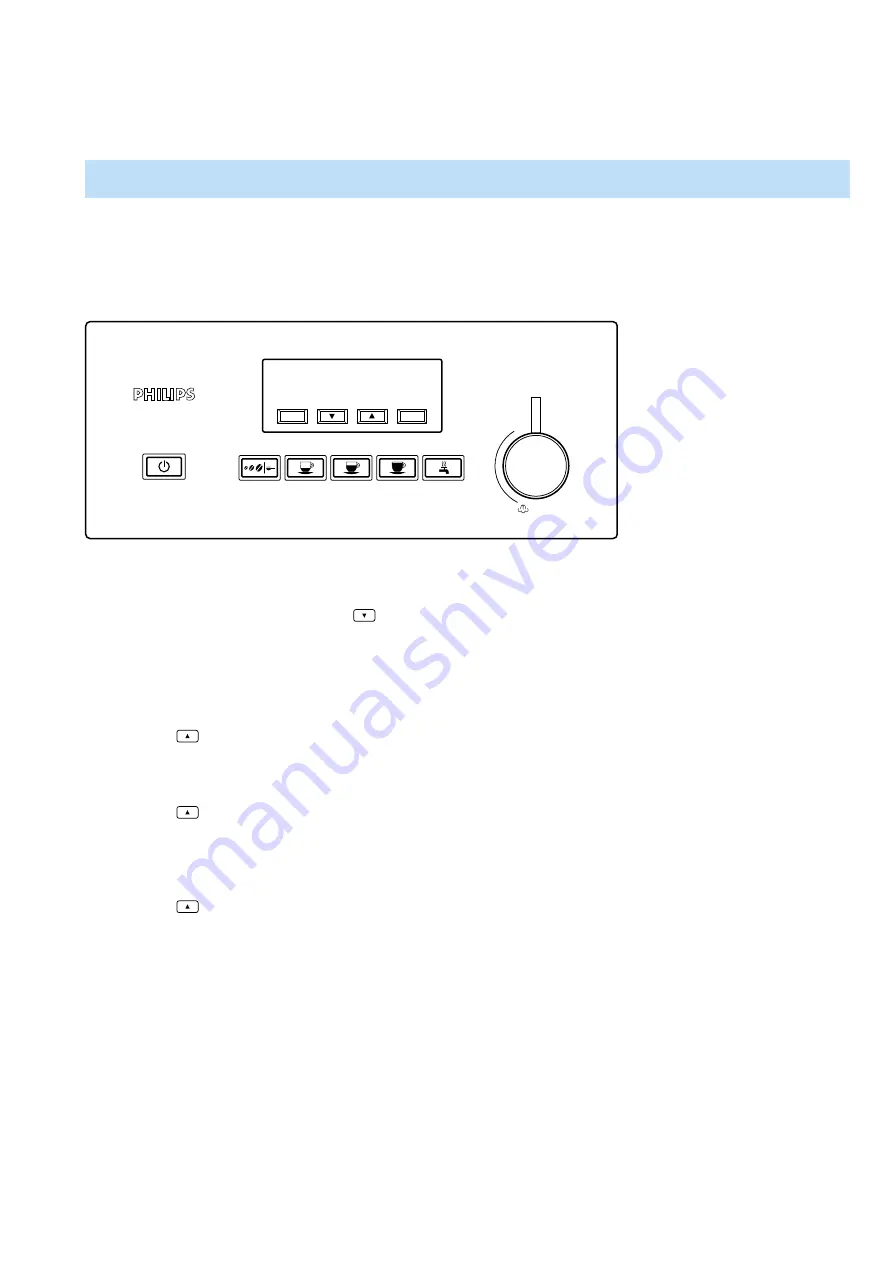

Service testroutines

This appliance has been equipped with special “service” routines to be able to check several functions of the appliance.

COUNTING PROCEDURE

With the counting procedure can be checked how (intense) the machine has been used by the consumer.

Items that are monitored:

Number of Coffee made, liters of water used, number of descaling procedures performed, number of cleaning/washing cycles

performed.

MENU

OK

OFF

ON

Entering the counting menu

1. Disconnect the appliance from mains.

2. Press simultaneously “MENU” and

button.

3. Connect the appliance to mains.

4. If above steps succeeded the display will show the following message

“TOT. COFFEE XXX”

”TOT. WATER XXX”

* where XXX is number of cups or Liters

5. Press

button to step to the next display message

”DESCALING XXX”

”WASHING XXX”

* where XXX is number of cycles performed

6. Press

button to step to the next display message

”SW RELEASE POW 15”

”SW RELEASE DIS 15”

* where POW 15 stands for power PCB software version release 1.5

* where DIS 15 stands for display PCB software version release 1.5

7. Press

button, step 4 will be repeated.

To leave the service/test mode unplug the appliance from the mains.

REPAIR INSTRUCTIONS