HD7817/60 /61 /62 /63 /65 /66 /67 /68 /69

2-7

Disassembly information

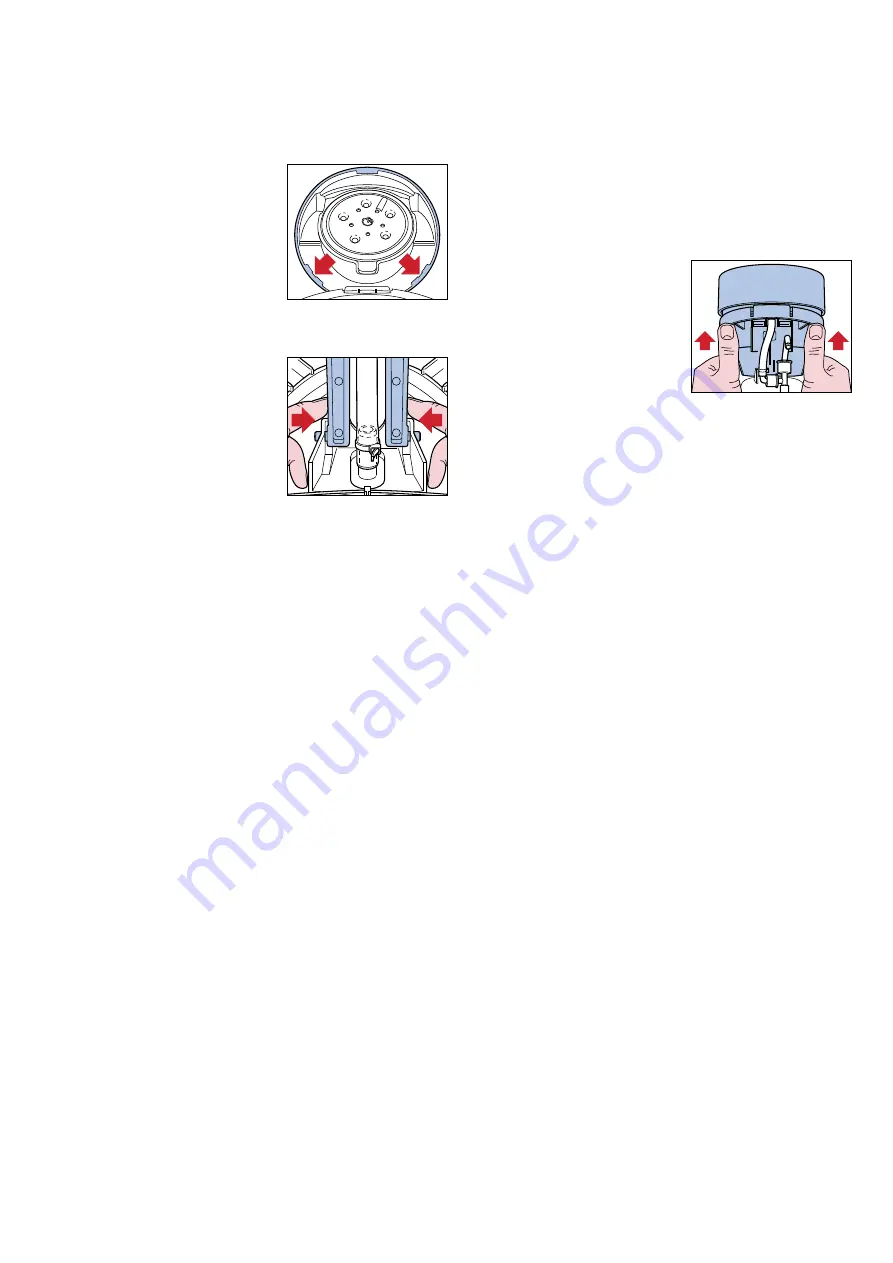

To remove the brew chamber lid cover handle as follows:

•

Place the screwdriver on the

positions (see picture 1) and

lift the cover over the snap

locks on both positions.

•

The cover lid can now be

lifted up a little and to

remove the complete cover

including lever and push rod

squeeze strongly with two

fingers both legs of the push

rod (see picture 2) to each

other, so that the two pins

will get out of the hinge

position on the brew

chamber.

•

To remove lever from lid cover, take a screwdriver and

bend carefully the two lips/ribs in the lid cover outwards

and push the lever with force out of the hinge.

•

Reassemble follow steps backwards, without using a

screwdriver.

To remove the back cover handle as follows:

•

Remove valve outlet.

•

Start at the upper side of the back cover and stick a

screwdriver into the 2 snap locks positions and gently

pull the back cover from the appliance so that a little

chink between back cover and brew chamber becomes

visible.

•

Put the screwdriver in to the 4 rectangular holes (snap

locks) at the back and gently pull the screwdriver such

away that the lips of the snap locks are bent outwards.

•

If all clicks positions are loose, it is possible to remove

the back cover.

•

Reassemble follow steps backwards.

picture 1

picture 2

Removing Brew chamber head handle as follows:

•

Disassemble back cover!

•

Place the appliance such a way that you are looking at

the boiler.

•

First remove the boiler from the snap lock position of the

brew chamber.

•

To remove the brew chamber,

use your both thumbs (see

picture 3) and push strongly

with a little distortion

(rotation) until the brew

chamber comes loose.

•

Reassemble follow above steps backwards.

To reach the components placed on the base handle as

follows:

•

First remove back cover, brew chamber and 3-way valve.

•

Remove both Torx T15 screws see exploded view in the

near of position

A

.

•

Bend the 2 click snap locks with a screwdriver (see base),

and the housing can now be removed.

•

To remove the rest of the housing unlock the last 4 snap

locks at the base and gently pull of the front cover.

•

To reassemble follow above steps backwards.

picture 3

Disassembly- and reassembly advice