Alignments

GB 67

L01.1A

8.

8. Alignments

Index:

1. General Alignment Conditions

2. Hardware Alignments

3. Software Alignments and Settings

Note:

•

The Service Default Mode (SDM) and Service Alignment

Mode (SAM) are described in chapter 5.

•

Menu navigation is done with the 'CURSOR UP, DOWN,

LEFT or RIGHT' keys of the remote control transmitter.

•

Figures can deviate slightly from the actual situation, due

to different set executions or software versions.

8.1

General Alignment Conditions

Perform all electrical adjustments under the following

conditions:

•

AC voltage and frequency: according to country’s

standard.

•

Connect the set to the AC power via an isolation

transformer.

•

Allow the set to warm up for approximately 20 minutes.

•

Measure the voltages and waveforms in relation to

chassis ground (with the exception of the voltages on the

primary side of the power supply). Never use the cooling

fins / plates as ground.

•

Test probe: Ri > 10 M

W

; Ci < 2.5 pF.

•

Use an

isolated

trimmer / screwdriver to perform the

alignments.

8.2

Hardware Alignments

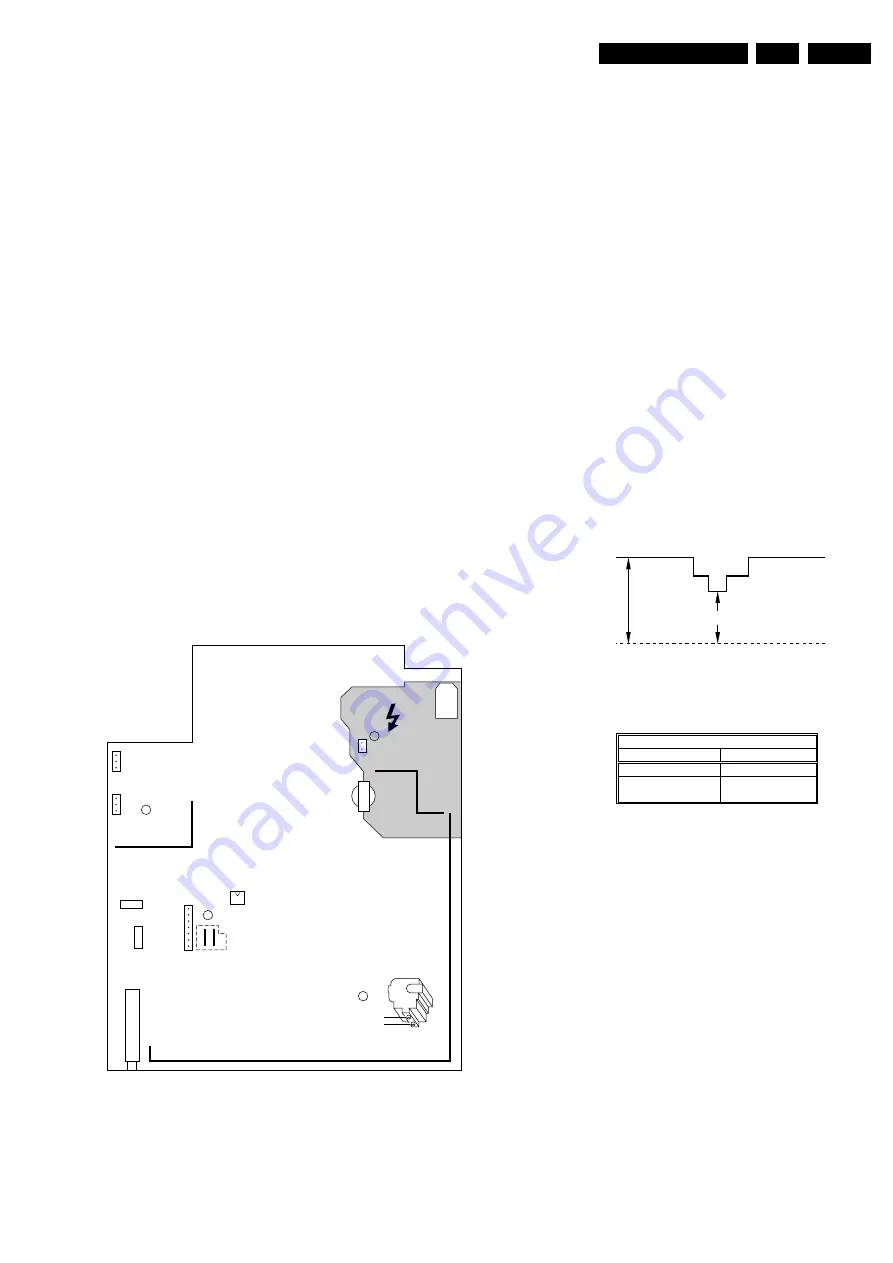

Figure 8-1

8.2.1

Vg2 Adjustment

1. Activate the SAM.

2. Go to the WHITE TONE sub menu.

3. Set the values of NORMAL RED, GREEN and BLUE to

40.

4. Go, via the MENU key, to the normal user menu and set

–

CONTRAST to zero.

–

BRIGHTNESS to minimum (OSD just visible in a

dark room).

5. Return to the SAM via the MENU key.

6. Connect the RF output of a pattern generator to the

antenna input. Test pattern is a 'black' picture (blank

screen on CRT

without

any OSD info).

7. Set the channel of the oscilloscope to 50 V/div and the

time base to 0.2 ms (external triggering on the vertical

pulse).

8. Ground the scope at the CRT panel and connect a 10:1

probe to one of the cathodes of the picture tube socket

(see diagram B).

9. Measure the cut off pulse during first full line after the

frame blanking (see Fig. 8-2). You will see two pulses,

one being the cut off pulse and the other being the white

drive pulse. Choose the one with the lowest value, this is

the cut off pulse.

10. Select the cathode with the highest V

DC

value for the

alignment. Adjust the V

cutoff

of this gun with the SCREEN

potentiometer (see Fig. 8-1) on the LOT to the correct

value (see table below).

11. Restore BRIGHTNESS and CONTRAST to normal (=

31).

Figure 8-2

Figure 8-3

8.2.2

Focusing

1. Tune the set to a circle or crosshatch test pattern (use an

external video pattern generator).

2. Choose picture mode NATURAL (or MOVIES) with the

‘SMART PICTURE’ button on the remote control

transmitter.

3. Adjust the FOCUS potentiometer (see Fig. 8-1) until the

vertical lines at 2/3 from east and west, at the height of

the centreline, are of minimum width without visible haze.

8.3

Software Alignments and Settings

Enter the Service Alignment Mode (see chapter 5). The SAM

menu will now appear on the screen.

Select one of the following alignments:

1. OPTIONS

2. TUNER

3. WHITE TONE

4. GEOMETRY

0231

0212

C

16532008_038.eps

160501

A

D

B

5445

LOT

Focus

Screen

VG2

5520

0240

0267

0268

7602

ComPair

1004

1002

1000 (TUNER)

9631

9641

SDM

0231

0V Ref.

CL 06532130_014.eps

131000

V

CUTOFF

[V

DC

]

max.

&872))92/7$*(//$5*(

6FUHHQVL]H

&XWRII>9@

´

RD

´´´

´´´´

DR

CL 16532008_056.pdf

220501

Summary of Contents for L01.1A

Page 48: ...Spare Parts List GB 88 L01 1A 10 ...

Page 78: ...56 L01 1A 7 Schematics and PWB s Layout PIP Panel Top View CL 16532010_010 eps 210301 ...

Page 79: ...Schematics and PWB s 57 L01 1A 7 Layout PIP Panel Bottom View CL 16532010_011 eps 210301 ...

Page 88: ...66 L01 1A 7 Schematics and PWB s Personal Notes Personal Notes ...