Circuit Description

GB 78

L01.1A

9.

format, 16:9, 14:9, 16:9 zoom, subtitle zoom and the Super-

Wide picture format

A line, written at the upper- or lower side of the screen, will

be larger at the screen centre when a fixed deflection current

is used. Therefore, the amplitude of the deflection current

must be increased when the spot approaches the centre of

the screen. This is called the East/West or pincushion

correction.

The ‘Ewdrive’ signal from pin 15 of IC7200 takes care for the

correct correction. It drives FET TS7400. It also corrects

breathing of the picture, due to beam current variations (the

EHT varies dependent of the beam current). This correction

is derived from the ‘EHTinformation’ line.

Two protections are built-in for the E/W circuit: over-current

and over-voltage protection. See paragraph Power Supply.

Panorama (if present)

The panorama function is only used in 16:9 sets. This is a

function to enable the 4:3 and Super-Wide feature. It drives

the ‘Bass_panorama’ line, to activate relay 1400. When this

relay is switched on, the capacitors 2453//2454 are added in

parallel to the default S-correction capacitors 2456//2457.

This results in an increased capacitance, a lower resonance

frequency of the line deflection coil and the S-correction

capacitors and therefore a less steep S-corrected line

deflection current.

9.5.4

Rotation (if present)

To cope with the different earth magnetism situations in the

world, a rotation coil is added. This coil is controlled by the

rotation circuitry (see diagram A15).

The amount of frame rotation is user controlled via the the

PWM output (pin 77) of the UOC.

With the tilt setting at ‘-10’, the PWM duty cycle is 0.1

(leftmost tuning).

With the setting at ‘+10’, the duty cycle is 0.9 (rightmost

tuning).

The output of amplifier IC7171 is a DC-voltage in the range

from 0 (user setting = -10), via 6 V (user setting = 0) to 12 V

(user setting = +10).

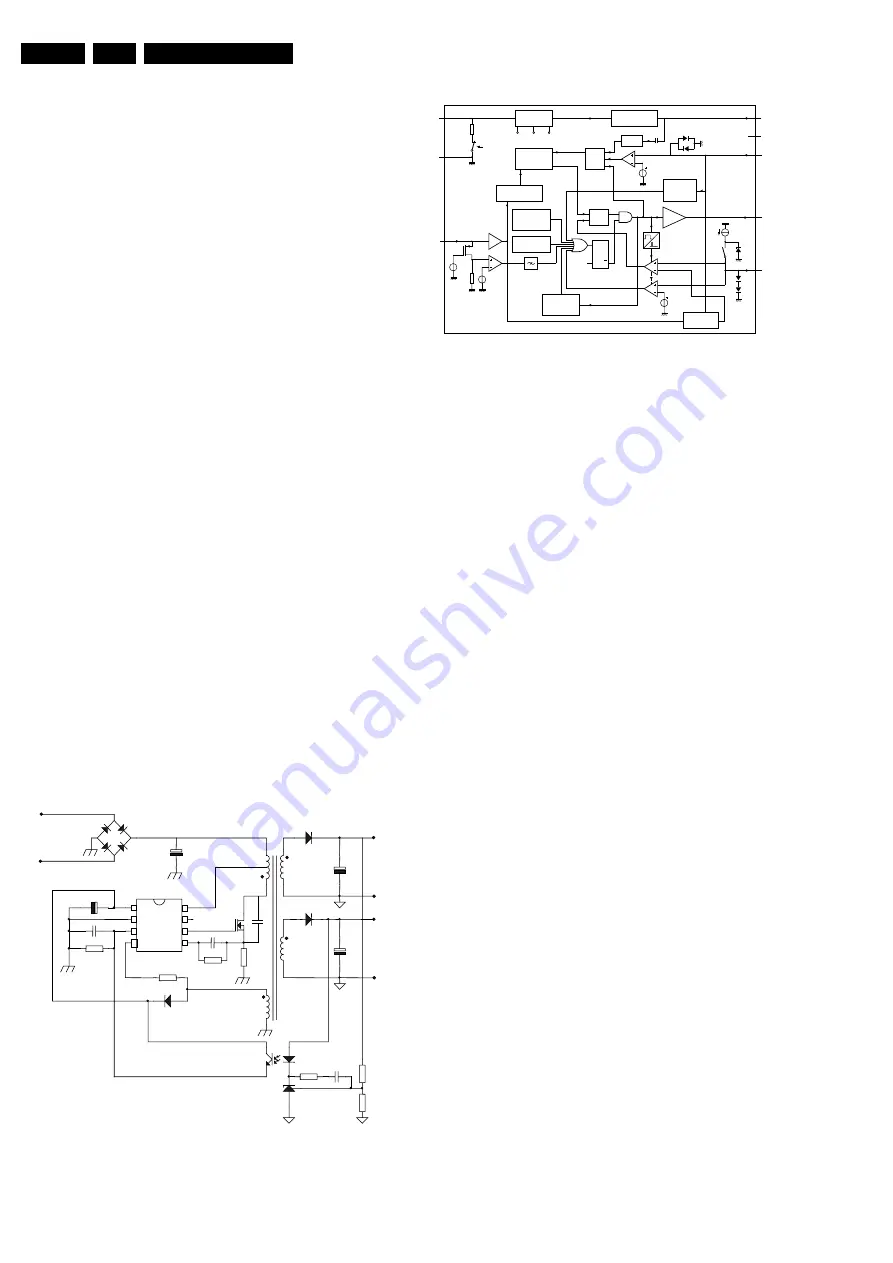

9.6

Power Supply

Figure 9-6

Figure 9-7

9.6.1

Introduction

The supply is a Switching Mode Power Supply (SMPS). The

frequency of operation varies with the circuit load. This

‘Quasi-Resonant Flyback’ behaviour has some important

benefits compared to a ‘hard switching’ fixed frequency

Flyback converter. The efficiency can be improved up to

90%, which results in lower power consumption. Moreover

the supply runs cooler and safety is enhanced.

The power supply starts operating when a DC voltage goes

from the rectifier bridge via T5520, R3532 to pin 8. The

operating voltage for the driver circuit is also taken from the

‘hot’ side of this transformer.

The switching regulator IC7520 starts switching the FET ‘on’

and ‘off’, to control the current flow through the primary

winding of transformer 5520. The energy stored in the

primary winding during the ‘on’ time is delivered to the

secondary windings during the ‘off’ time.

The ‘MainSupply’ line is the reference voltage for the power

supply. It is sampled by resistors 3543 and 3544 and fed to

the input of the regulator 7540/6540. This regulator drives the

feedback optocoupler 7515 to set the feedback control

voltage on pin 3 of 7520.

The power supply in the set is ‘on’ any time AC power goes

to the set.

Derived Voltages

The voltages supplied by the secondary windings of T5520

are:

•

‘MainAux’ for the audio circuit (voltage depends on set

execution, see table below),

•

3.3 V and 3.9 V for the microprocessor and

•

‘MainSupply’ for the horizontal output (voltage depends

on set execution, see table below).

Other supply voltages are provided by the LOT. It supplies

+50 V (only for large screen sets), +13 V, +8 V, +5 V and a

+200 V source for the video drive. The secondary voltages of

the LOT are monitored by the ‘EHTinformation’ lines. These

lines are fed to the video processor part of the UOC IC7200

on pins 11 and 34.

This circuit will shut ‘off’ the horizontal drive in case of over-

voltage or excessive beam current.

Demag

4

Ctrl

Gnd

Vcc

Drain

HVS

Driver

Sense

3

2

1

5

6

7

8

V

LINE

V

TEA1507

IN

C

IN

V

CC

C

D

R

SENSE

C

SS

R

SS

V

OUT

N

S

N

P

N

Vcc

CL 16532020_074.eps

120401

SUPPLY

MANAGEMENT

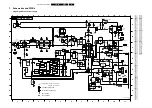

internal

supply

UVLO

start

M-level

VCC

1

2

3

GND

S1

CTRL

FREQUENCY

CONTROL

VOLTAGE

CONTROLLED

OSCILLATOR

LOGIC

LOGIC

OVER-

VOLTAGE

PROTECTION

OVERPOWER

CL 16532020_073.eps

060701

PROTECTION

short

winding

soft

start

S2

OVER-

TEMPERATURE

PROTECTION

S

Q

R

UVLO

Q

MAXIMUM

ON-TIME

PROTECTION

POWER-ON

RESET

−

1

VALLEY

TEA1507

100 mV

clamp

DRIVER

START-UP

CURRENT SOURCE

0.75 V

0.5 V

5

Isense

6

DRIVER

4

DEM

8

DRAIN

7

HVS

n.c.

OCP

LEB

blank

Iss

2.5 V

burst

detect

Summary of Contents for L01.1A

Page 48: ...Spare Parts List GB 88 L01 1A 10 ...

Page 78: ...56 L01 1A 7 Schematics and PWB s Layout PIP Panel Top View CL 16532010_010 eps 210301 ...

Page 79: ...Schematics and PWB s 57 L01 1A 7 Layout PIP Panel Bottom View CL 16532010_011 eps 210301 ...

Page 88: ...66 L01 1A 7 Schematics and PWB s Personal Notes Personal Notes ...