Safety & Maintenance Instructions, Warnings, and Notes

GB 4

L01.1A

2.

2. Safety & Maintenance Instructions, Warnings, and Notes

2.1

Safety Instructions For Repairs

Safety regulations require that during a repair:

•

Due to the ‘hot’ parts of this chassis, the set must be

connected to the AC power via an isolation transformer.

•

Safety components, indicated by the symbol

, should

be replaced by components identical to the original ones.

•

When replacing the CRT, safety goggles must be worn.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay particular attention to

the following points:

•

General repair instruction: as a strict precaution, we

advise you to re-solder the solder connections through

which the horizontal deflection current is flowing, in

particular:

–

all pins of the line output transformer (LOT)

–

fly-back capacitor(s)

–

S-correction capacitor(s)

–

line output transistor

–

pins of the connector with wires to the deflection coil

–

other components through which the deflection

current flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections and is therefore

only necessary for television sets more than two years old.

•

Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

•

Check the insulation of the AC power cord for external

damage.

•

Check the strain relief of the AC power cord for proper

function, to prevent the cord from touching the CRT, hot

components, or heat sinks.

•

Check the electrical DC resistance between the AC plug

and the secondary side (only for sets that have an

isolated power supply). Do this as follows:

1. Unplug the AC power cord and connect a wire

between the two pins of the AC plug.

2. Turn on the main power switch (keep the AC power

cord unplugged!).

3. Measure the resistance value between the pins of

the AC plug and the metal shielding of the tuner or

the aerial connection of the set. The reading should

be between 4.5 M

9

and 12 M

9

.

4. Switch the TV OFF and remove the wire between the

two pins of the AC plug.

•

Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

2.2

Maintenance Instructions

It is recommended to have a maintenance inspection carried

out by qualified service personnel. The interval depends on

the usage conditions:

•

When the set is used under normal circumstances, for

example in a living room, the recommended interval is

three to five years.

•

When the set is used in an environment with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is one year.

•

The maintenance inspection includes the following

actions:

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on

the chassis.

3. Clean the picture tube panel and the neck of the

picture tube.

2.3

Warnings

•

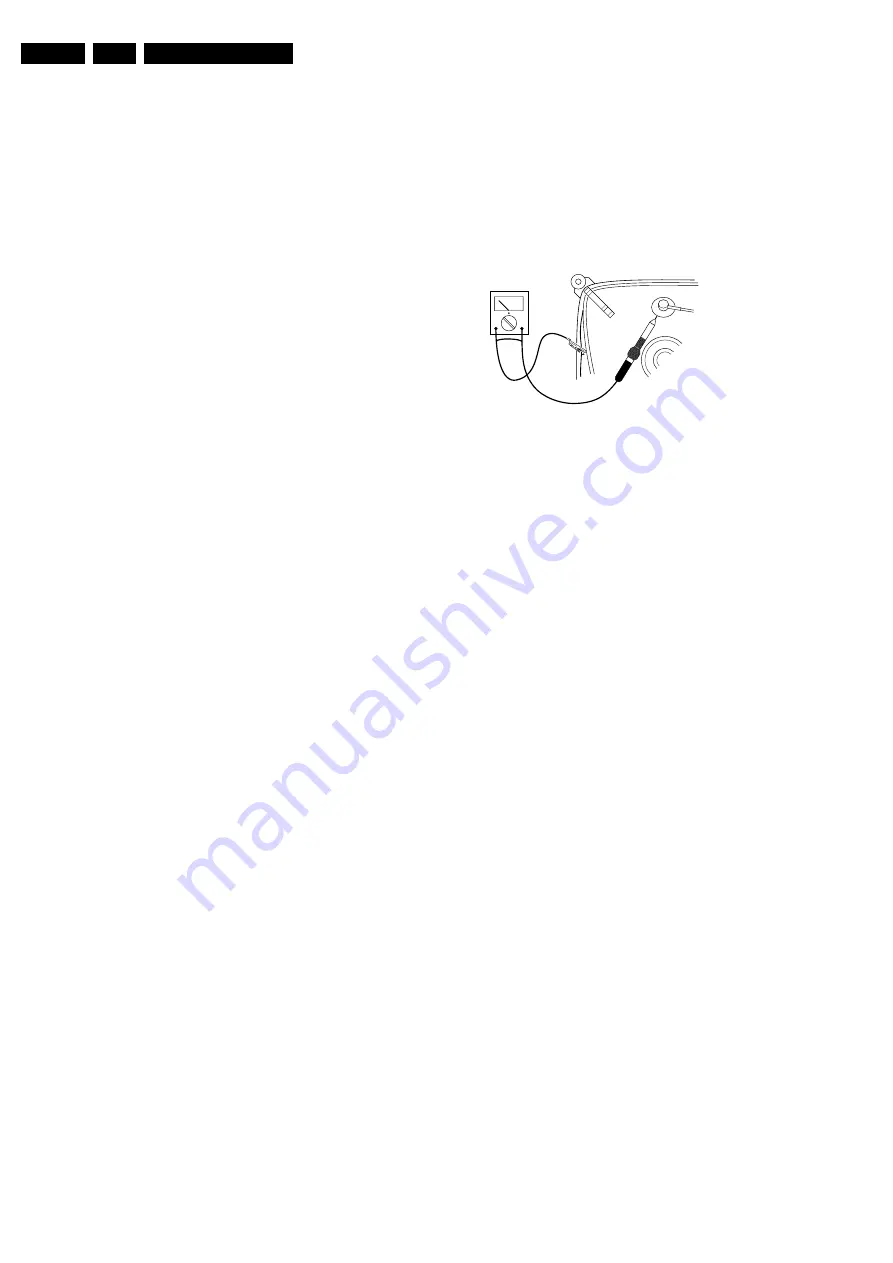

In order to prevent damage to ICs and transistors, avoid

all high voltage flashovers. In order to prevent damage to

the picture tube, use the method shown in Fig. 2-1, to

discharge the picture tube. Use a high voltage probe and

a multi-meter (position VDC). Discharge until the meter

reading is 0 V (after approx. 30 s).

Figure 2-1

•

All ICs and many other semiconductors are susceptible

to electrostatic discharges (ESD)

. Careless handling

during repair can reduce life drastically. When repairing,

make sure that you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this

potential. Available ESD protection equipment:

–

Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable, and ground cable)

4822 310 10671.

–

Wristband tester 4822 344 13999.

•

Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. Adjustment of this unit during repair is therefore

not recommended.

•

Be careful during measurements in the high voltage

section and on the picture tube.

•

Never replace modules or other components while the

unit is switched ON.

•

When you align the set, use plastic rather than metal

tools. This will prevent any short circuits and the danger

of a circuit becoming unstable.

2.4

Notes

•

Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (

), or hot ground (

),

depending on the area of circuitry being tested.

•

The voltages and waveforms shown in the diagrams are

indicative. Measure them in the Service Default Mode

(see chapter 5) with a color bar signal and stereo sound

(L: 3 kHz, R: 1 kHz unless stated otherwise) and picture

carrier at 475.25 MHz (PAL) or 61.25 MHz (NTSC,

channel 3).

•

Where necessary, measure the waveforms and voltages

with (

) and without (

) aerial signal. Measure the

voltages in the power supply section both in normal

operation (

) and in standby (

). These values are

indicated by means of the appropriate symbols.

•

The picture tube panel has printed spark gaps. Each

spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

•

The semiconductors indicated in the circuit diagram and

in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

V

CL 26532098/042

140792

Summary of Contents for L01.1A

Page 48: ...Spare Parts List GB 88 L01 1A 10 ...

Page 78: ...56 L01 1A 7 Schematics and PWB s Layout PIP Panel Top View CL 16532010_010 eps 210301 ...

Page 79: ...Schematics and PWB s 57 L01 1A 7 Layout PIP Panel Bottom View CL 16532010_011 eps 210301 ...

Page 88: ...66 L01 1A 7 Schematics and PWB s Personal Notes Personal Notes ...