Service Modes, Error Codes, and Fault Finding

5.

•

6 short blinks followed by a pause of 3 s,

•

1 long blink of 3 s to finish the sequence,

•

the sequence starts again.

5.6

Protections

If a fault situation is detected an error code will be generated

and if necessary the set will be put in the protection mode.

Blinking of the red LED at a frequency of 3 Hz indicates the

protection mode. In some error cases the microprocessor does

not put the set in the protection mode. The error codes of the

error buffer can be read via the service menu (SDAM), the

blinking LED procedure or via ComPair.

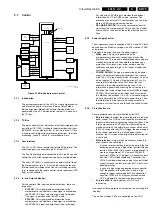

To get a quick diagnosis the chassis has two service modes

implemented:

•

The Customer Service Mode (CSM).

•

The Service Default Alignment Mode (SDAM). Start-up of

the set in a predefined way and adjustment of the set via a

menu and with the help of test patterns.

5.7

Repair Tips

Below some failure symptoms are given, followed by a repair

tip.

•

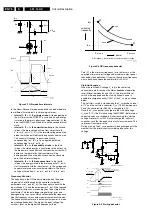

Set is dead and makes hiccupping sound. “MainSupply”

is available. Hiccupping stops when de-soldering L5561,

meaning that problem is in the “MainSupply” line. No output

voltages at LOT, no horizontal deflection. Reason: line

transistor 7460 is defective.

•

Set is dead, and makes no sound. Check power supply

IC 7520. Result: voltage at pins 1, 3, 4, 5 and 6 are about

180 V and pin 8 is 0 V. The reason why the voltage on

these pins is so high is because the output driver (pin 6)

has an open load. That is why MOSFET 7521 is not able to

switch. Reason: feedback resistor 3523 is defective.

Caution: be careful measuring on the gate of 7521;

circuitry is very high ohmic and can easily be damaged!

•

Set is in hiccup mode and shuts down after 8 s. Blinking

LED (set in SDM mode) indicates error 5. As it is unlikely

that the “POR” and “+8V protection” happen at the same

time, measure the “+8V”. If this voltage is missing, check

transistor 7480.

•

Set is non-stop in hiccup mode. Set is in over current

mode; check the secondary sensing (opto coupler 7515)

and the “MainSupply” voltage. Signal “Stdby_con” must be

logic low under normal operation conditions and goes to

high (3.3 V) under standby and fault conditions.

•

Set turns on, but without picture and sound. The screen

shows snow, but OSD and other menus are okay. Blinking

LED procedure indicates error 11, so problem is expected

in the tuner (pos. 1000). Check presence of supply

voltages. As “5V” at pin 5 and 7 are okay,

“VT_supply” at pin 9 is missing. Conclusion: resistor 3460

is defective.

•

Set turns on, but with a half screen at the bottom.

Sound is okay. Blinking LED (set in SDM mode) indicates

error 3. Check “11V” and “+50V”. If they are okay,

problem is expected in the vertical amplifier IC 7471.

Measure with a scope the waveform on pin 17 of the UOC.

Measure also at pin 1 of IC 7471. If here the signal is

missing, a defective resistor R3244 causes the problem

Summary of Contents for L01.1L AC

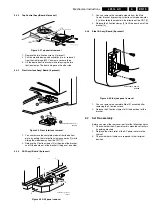

Page 6: ...Directions for Use EN 6 L01 1L AC 3 3 Directions for Use 3 1 16 9 Sets ...

Page 7: ...Directions for Use EN 7 L01 1L AC 3 ...

Page 8: ...Directions for Use EN 8 L01 1L AC 3 ...

Page 9: ...Directions for Use EN 9 L01 1L AC 3 ...

Page 10: ...Directions for Use EN 10 L01 1L AC 3 ...

Page 11: ...Directions for Use EN 11 L01 1L AC 3 ...

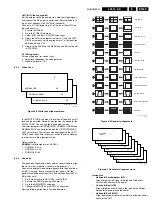

Page 12: ...Directions for Use EN 12 L01 1L AC 3 ...

Page 13: ...Directions for Use EN 13 L01 1L AC 3 ...

Page 14: ...Directions for Use EN 14 L01 1L AC 3 ...

Page 15: ...Directions for Use EN 15 L01 1L AC 3 ...

Page 16: ...Directions for Use EN 16 L01 1L AC 3 Personal Notes ...

Page 17: ...Directions for Use EN 17 L01 1L AC 3 3 2 4 3 Sets Personal Notes ...

Page 42: ...Spare Parts List EN 82 L01 1L AC 10 10 Spare Parts List Not applicable yet ...

Page 43: ...Revision List EN 83 L01 1L AC 11 11 Revision List First release ...