Circuit Description

9.

The moment that the voltage on pin 1 drops below the 'under

voltage lock out' level (UVLO =

±

9 V), the IC will stop switching

and will enter a safe restart from the rectified mains voltage.

Operation

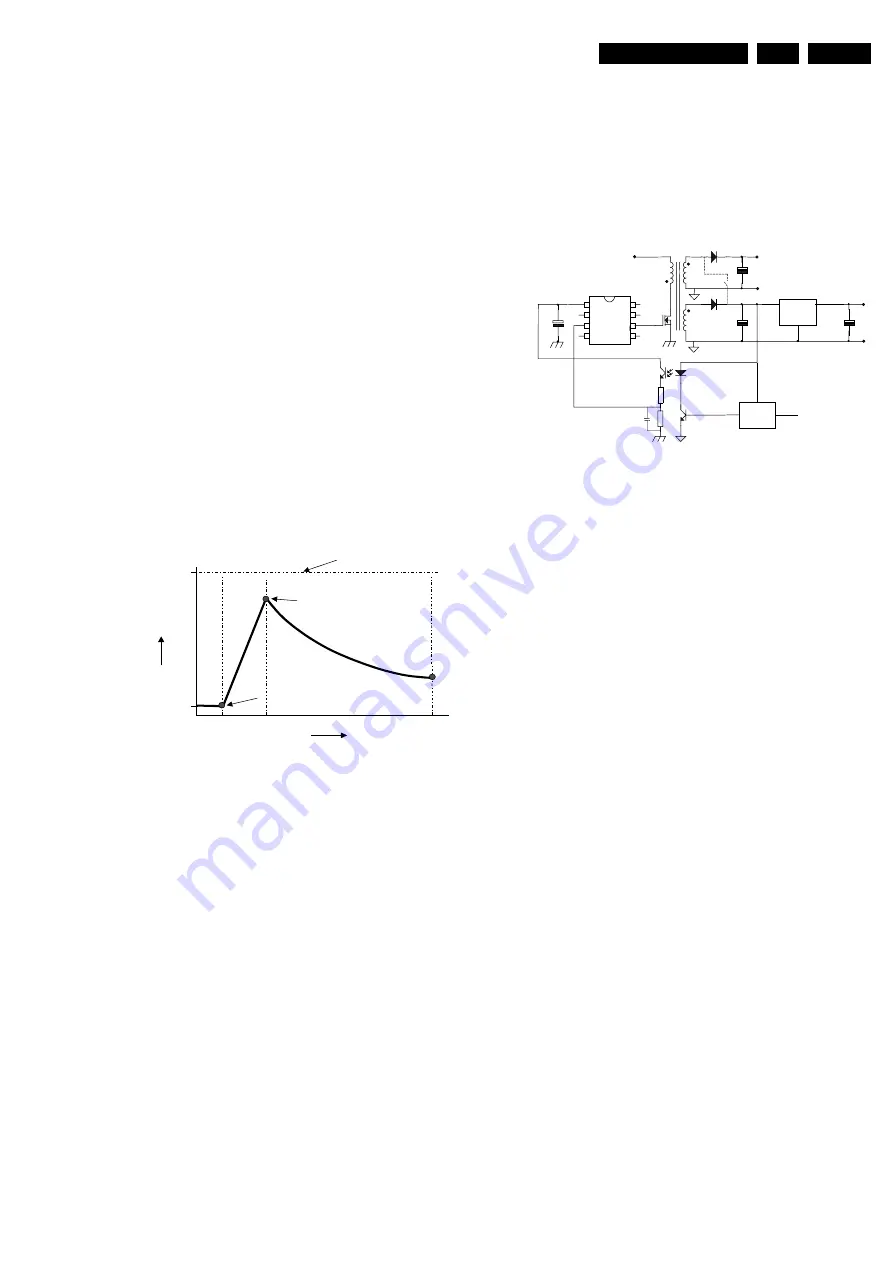

The supply can run in three different modes depending on the

output power:

•

Quasi-Resonant mode (QR). The 'QR' mode, described

above, is used during normal operation. This will give a

high efficiency.

•

Frequency Reduction mode (FR). The 'FR' mode (also

called 'VCO' mode) is implemented to decrease the

switching losses at low output loads. In this way, the

efficiency at low output powers is increased, which enables

power consumption smaller than 3 W during stand-by. The

voltage at the pin 3 (Ctrl) determines where the frequency

reduction starts. An external Ctrl voltage of 1.425 V

corresponds with an internal VCO level of 75 mV. This

fixed VCO level is called V_vco,start . The frequency will be

reduced in relation to the VCO voltage between 75 mV and

50 mV (at levels larger than 75 mV, Ctrl voltage < 1.425V,

the oscillator will run on maximum frequency f_oscH = 175

kHz typically). At 50 mV (V_vco,max), the frequency is

reduced to the minimum level of 6 kHz. Valley switching is

still active in this mode.

•

Minimum Frequency mode (MinF). At VCO levels below

50 mV, the minimum frequency will remain on 6 kHz, which

is called the 'MinF' mode. Because of this low frequency, it

is possible to run at very low loads without having any

output regulation problems.

Figure 9-10 Different supply modes

Safe-Restart Mode

This mode is introduced to prevent the components from being

destroyed during eventual system fault conditions. It is also

used for the Burst mode. The Safe-Restart mode will be

entered if it is triggered by one of the following functions:

•

Over voltage protection,

•

Short winding protection,

•

Maximum 'on time' protection,

•

V_cc reaching UVLO level (fold back during overload),

•

Detecting a pulse for Burst mode,

•

Over temperature protection.

When entering the Safe-Restart mode, the output driver is

immediately disabled and latched. The V_cc winding will not

charge the V_cc capacitor anymore and the V_cc voltage will

drop until UVLO is reached. To recharge the V_cc capacitor,

the internal current source (I_(restart)(vcc) ) will be switched

'on' to initiate a new start-up sequence as described before.

This Safe-Restart mode will persist until the controller detects

no faults or burst triggers.

Standby

The set goes to Standby in the following cases:

•

After pressing the 'standby' key on the remote control.

•

When the set is in protection mode.

In Standby, the power supply works in 'burst mode'. Burst

mode can be used to reduce the power consumption below 1

W at stand-by. During this mode, the controller is active

(generating gate pulses) for only a short time and for a longer

time inactive waiting for the next burst cycle.

In the active period, the energy is transferred to the secondary

and stored in the buffer capacitor C_stab in front of the linear

stabilizer (see figure below). During the inactive period, the

load (e.g. microprocessor) discharges this capacitor. In this

mode, the controller makes use of the Safe-Restart mode.

Figure 9-11 Supply standby mode (burst mode)

The system enters burst mode standby when the

microprocessor activates the 'Stdby_con' line. When this line is

pulled high, the base of TS7541 is allowed to go high. This is

triggered by the current from collector TS7542. When TS7541

turns 'on', the opto-coupler (7515) is activated, sending a large

current signal to pin 3 (Ctrl). In response to this signal, the IC

stops switching and enters a 'hiccup' mode. This burst

activation signal should be present for longer than the 'burst

blank' period (typically 30 s): the blanking time prevents false

burst triggering due to spikes.

Burst mode standby operation continues until the

microcontroller pulls the 'Stdby_con' signal low again. The

base of TS7541 is unable to go high, thus cannot turn 'on'. This

will disable the burst mode. The system then enters the start-

up sequence and begins normal switching behavior.

For a more detailed description of one burst cycle, three time

intervals are defined:

•

t1: Discharge of V_cc when gate drive is active. During

the first interval, energy is transferred, which result in a

ramp-up of the output voltage (V_stab) in front of the

stabilizer. When enough energy is stored in the capacitor,

the IC will be switched 'off' by a current pulse generated at

the secondary side. This pulse is transferred to the primary

side via the opto coupler. The controller will disable the

output driver (safe restart mode) when the current pulse

reaches a threshold level of 16 mA into the 'Ctrl' pin. A

resistor R1 (R3519) is placed in series with the opto

coupler, to limit the current going into the 'Ctrl' pin.

Meanwhile the V_cc capacitor is discharged but has to stay

above V_uvlo .

•

t2: Discharge of V_cc when gate drive is inactive.

During the second interval, the V_cc is discharged to

V_uvlo. The output voltage will decrease depending on the

load.

•

t3: Charge of V_cc when gate drive is inactive. The third

interval starts when the UVLO is reached. The internal

current source charges the V_cc capacitor (also the soft

start capacitor is recharged). Once the V_cc capacitor is

charged to the start-up voltage, the driver is activated and

a new burst cycle is started.

frequency limit

P

OUT_MIN

P

OUT_MAX

f

oscL

= 6 kHz

f

oscH

= 175 kHz

kH

MinF FR QR

power

switching

frequency

V

VCO,start

V

VCO,max

Multi mode operation

CL 16532020_080.eps

100401

Demag

4

Ctrl

Gnd

Vcc Drain

HVS

Driver

Sense

3

2

1

5

6

7

8

Burst-Mode stand-by on/off

from microprocessor

Linear

stabilizer

V

STAB

V

µ

C

C

STAB

C

Vcc

V

CC

R

1

Current pulse

generator

V

IN

Basic Burst mode configuration

CL 16532020_081.eps

100401

Summary of Contents for L01.1L AC

Page 6: ...Directions for Use EN 6 L01 1L AC 3 3 Directions for Use 3 1 16 9 Sets ...

Page 7: ...Directions for Use EN 7 L01 1L AC 3 ...

Page 8: ...Directions for Use EN 8 L01 1L AC 3 ...

Page 9: ...Directions for Use EN 9 L01 1L AC 3 ...

Page 10: ...Directions for Use EN 10 L01 1L AC 3 ...

Page 11: ...Directions for Use EN 11 L01 1L AC 3 ...

Page 12: ...Directions for Use EN 12 L01 1L AC 3 ...

Page 13: ...Directions for Use EN 13 L01 1L AC 3 ...

Page 14: ...Directions for Use EN 14 L01 1L AC 3 ...

Page 15: ...Directions for Use EN 15 L01 1L AC 3 ...

Page 16: ...Directions for Use EN 16 L01 1L AC 3 Personal Notes ...

Page 17: ...Directions for Use EN 17 L01 1L AC 3 3 2 4 3 Sets Personal Notes ...

Page 42: ...Spare Parts List EN 82 L01 1L AC 10 10 Spare Parts List Not applicable yet ...

Page 43: ...Revision List EN 83 L01 1L AC 11 11 Revision List First release ...