LRC2410 Installation Instructions, Part No. CDCS000314 Rev. A 7/11

Page 1

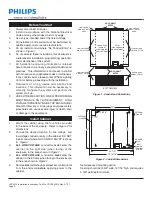

LRC2410

8X20A Relay Control Panel

BACnet MS/TP Enabled

INSTALLATION INSTRUCTIONS

WARNING

To reduce the risk of death, injury or property damage from fire, electric shock, cuts,

abrasions, falling parts, and other hazards:

•

Service of the equipment must be performed by qualified service personnel.

•

Installation and maintenance must be performed by a person familiar with the construction

and operation of this product and any hazards involved. All applicable codes and ordinances

must be followed.

•

Read this document before installing, servicing, or maintaining this equipment. These

instructions do not cover all installation, service, and maintenance situations. If your situation

is not covered, or if you do not understand these instructions or additional information is

required, contact

Philips Lighting Controls.

WARNING

Before installing, servicing, or maintaining this equipment, follow these general precautions.

To reduce the risk of electrocution:

•

Make sure the equipment is properly grounded.

•

Always de-energize any equipment before connecting to, disconnecting from, or

servicing the equipment.

To reduce the risk of fire:

•

Use supply conductors with a minimum installation temperature rating as specified.

To reduce the risk of personal injury from cuts, abrasions:

•

Wear gloves to prevent cuts or abrasions from sharp edges when removing from

carton, handling and maintaining this equipment.

•

Do not install a damaged equipment.

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS!

SAVE THESE INSTRUCTIONS AND DELIVER TO OWNER AFTER INSTALLATION

!

!