GC9620 - GC9650

21-23

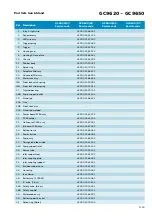

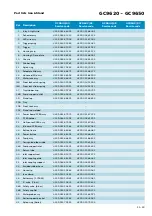

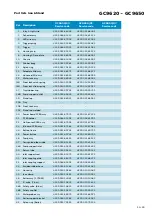

6.5. Troubleshooting Tips

TS tip #1

TS tip #2

TS tip #3

TS tip #4

TS tip #5

TS tip #6

TS tip #7

TS tip #8

TS tip #9

No pumping sound, fault could be on:

Pump

check by apply AC voltage directly

Power PCBA

check by driving a known good pump

Connection

check wire continuity

a)

b)

c)

2.

1.

No buzzer sound, fault should be on Power

PCBA

Other LEDs do not light up as specified, fault should be on one of

PCBAs or interconnection

4.

1. Zero-crossing detection circuit error, fault should be on

PCBA

1. LEDs do not light up as specified, fault should be on one of

PCBAs or

interconnection

1. Iron temperature sensing circuit error, fault could be on:

Thermistor

check the resistance, should be around 200+ k

Ω

)

Power PCBA

check by test another board

Connection

check wire continuity, especially hose cord

a)

b)

c)

Thermistor

check the resistance, should be around 200+ k

Ω

)

Power PCBA

check by test another board

Connection

check wire continuity

a)

b)

c)

Iron heater power does not show in the power meter, fault could be due to:

1.

Iron is too hot

cool down and try again

Iron fuse or heating element Open Circuit

check resistance between Iron Live and Neutral signal

Power PCBA

check by test another board

a)

b)

c)

1. Boiler heater power does not show in the power meter, fault could be due to:

Boiler is too hot

cool down and try again

Boiler fuse or heating element Open Circuit

check resistance between Boiler Live and Neutral signal

Power PCBA

check by test another board

a)

b)

c)

1. Boiler temperature sensing circuit error, fault could be due to:

1. E-valve does not open when steam trigger is pressed:

If iron LED still keeps blinking, trigger press is not detected, fault could be on:

-

If iron LED becomes steady on when press steam trigger, and system shows completed Self-Check mode

successfully after release the trigger

check E-valve related parts and Power PCBA

-

1. Water probe error, fault could be due to:

There is water inside boiler

pour out water and test again

Probe reaches end of life

replace probe and test again

Connection

check wire continuity

Power PCBA

check by test another board

a)

Trigger mechanism or hose cord connection

disconnect connector 9016 from Power PCBA

and measure continuity between the black wire (pin1) and iron Neutral, it should be short circuit

when trigger is pressed, and open circuit when trigger is released.

a)

b)

Power PCBA

check by test another board

b)

c)

d)

Iron LED and hose cord wiring

disconnect connector 9016 from Power PCBA and measure across

pin 3 at female side and iron Neutral to check diode characteristics

Power PCBA

check by test another board

a)

b)

Iron LED does not light up as specified, fault could be on:

3.

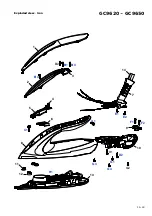

Repair Instruction