GC6048

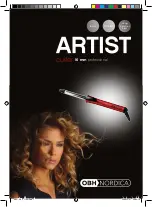

DISASSEMBLY ADVICE & PARTS LIST - STAND

disassemble

SAFETY CAP 21

SWITCH PANEL 22

remove

screw F (2x)

F

F

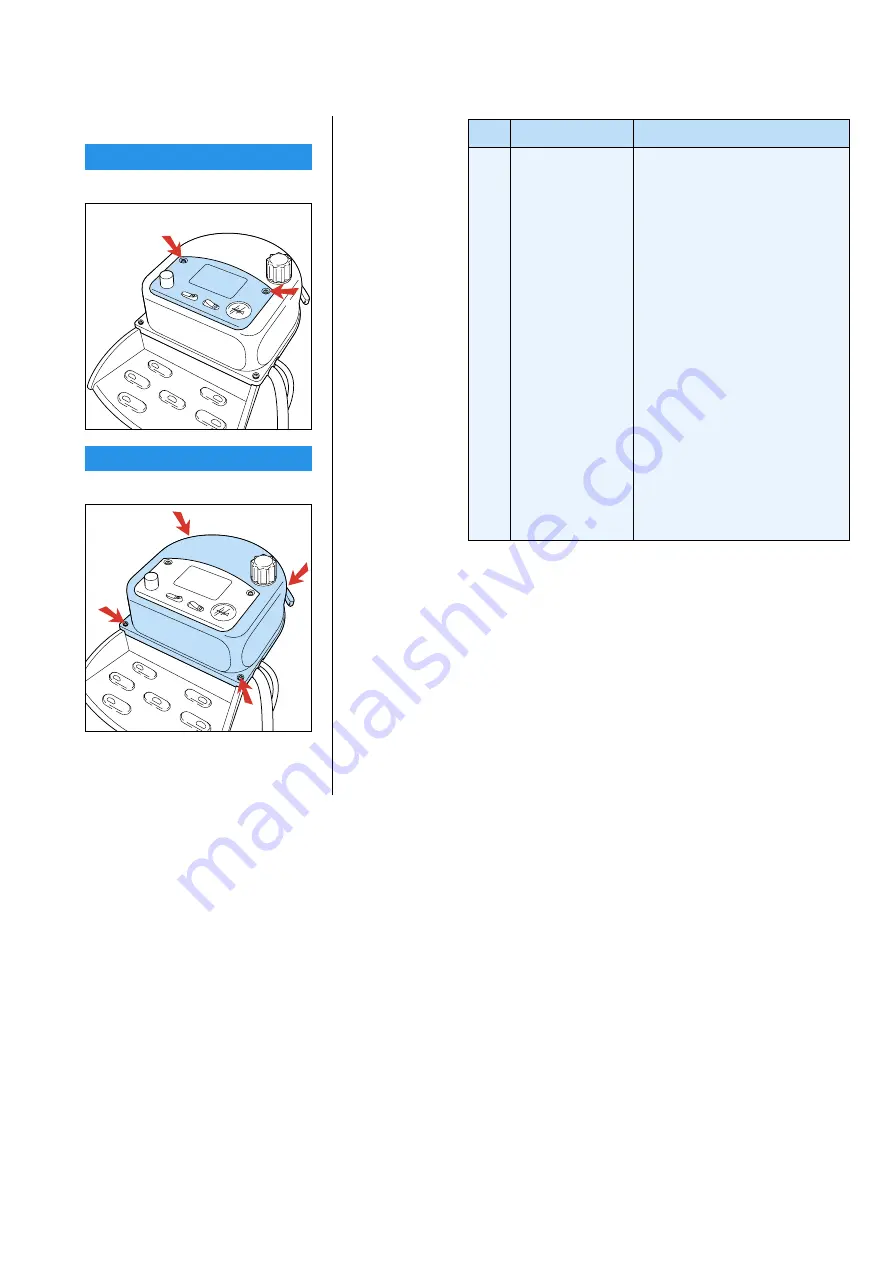

SUPERIOR STAND 23

remove

screw G (4x)

G

G

G

G

remove the

SUPERIOR STAND 23

now and you will see the respective

parts of the Boiler

REPAIR INSTRUCTIONS - STAND

- For disassembly, you will need a Torx screwdriver 362 TR T20 x 100.

- The thermostat fi tted to the

SOLEPLATE UNIT 13

has been adjusted by supplier

and secured by glue.

To avoid disfunction of the iron,

NEVER

readjust the thermostat.

- To avoid leakage of the sealings and damage to the components in and on the

boiler,

NEVER

clean the boiler with vinegar, a descaling agent or other chemicals.

- The boiler doesn’t contain serviceable parts.

NEVER

disassemble the boiler body

or component and/or components on and in the boiler.

- The boiler is required to be rinsed after every ten times use.

-

ALWAYS REPLACE BOILER (Pos 33) WHEN:

• the mechanical safety valve has been activated.

• the boiler thermostat or hand –resettable safety thermostat are open.

• the electrovalve fails or the sieve is soiled with scale.

4-5

Pos

Service code

Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35a

35b

36

37

38

39

9965 000 13348

9965 000 13349

9965 000 13313

9965 000 13251

9965 000 13314

9965 000 13315

9965 000 13328

9965 000 01900

9965 000 13316

9965 000 01782

9965 000 13317

9965 000 13318

9965 000 13330

4822 462 71999

9965 000 13320

9965 000 13321

9965 000 13322

9965 000 13329

9965 000 08246

9965 000 13350

Safety cap

Switch panel

Superior stand

Main switch

Tray rubber foot

Iron clip

Steam dial

Steam regulation

Electrovalve

Filling hole gasket

Lateral Alu protection

Complete tray

Complete boiler unit, Inox

Boiler rubber feet

Supply cable (Europe)

Supply cable (Italy)

Inferior stand

Boiler lamp

Funnel and Anticalc

Manometer