H

EAD

A

SSEMBLY

: 80

MM

F

AN

A

SSEMBLY

0 2 . 9 6 7 8 . 0 0 1 0 G

85

3

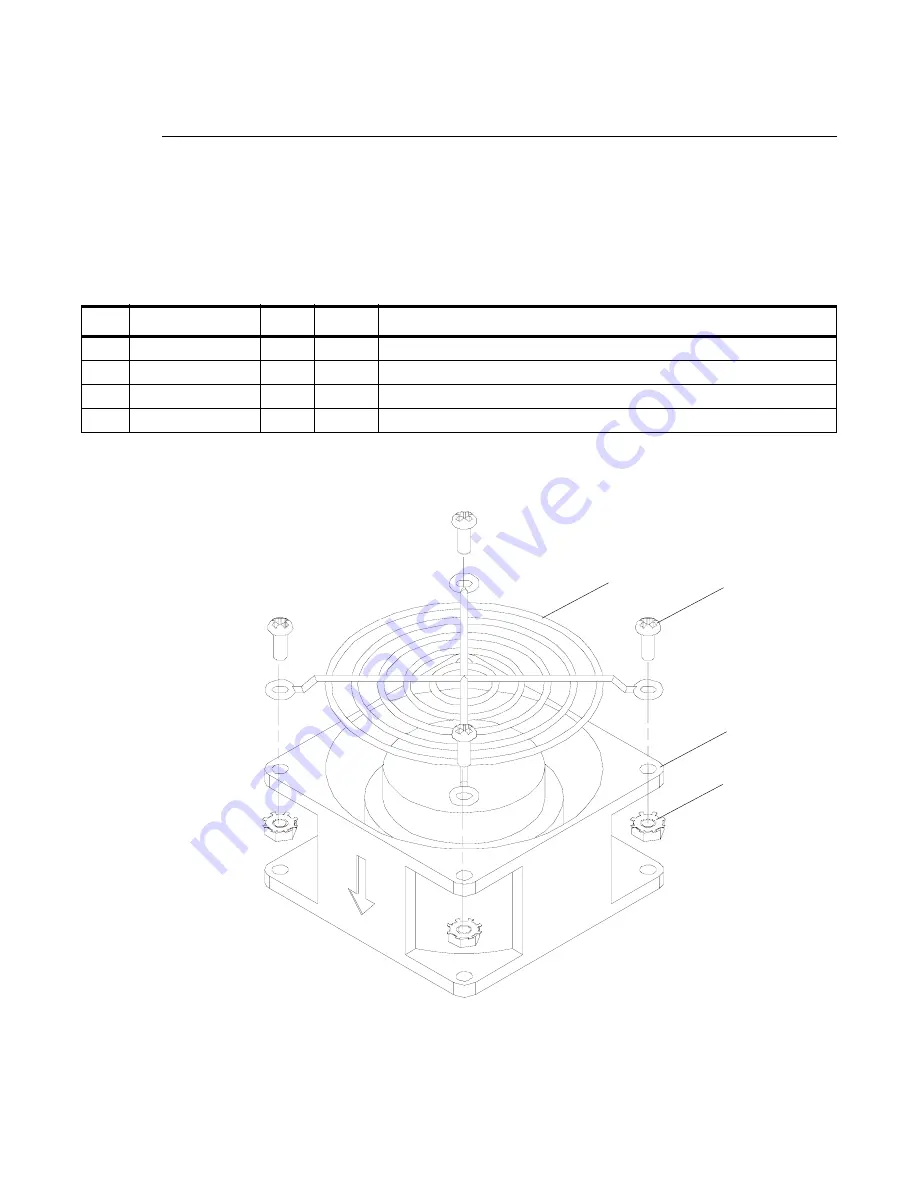

80mm Fan Assembly

21.9678.0619 Rev B

Refer to

Figure 3-4: 80mm Fan Assembly

No.

Item

Qty.

UM.

Description

1

40.7145.0004

1

EA

FAN, TUBEAXIAL 80 X 80 X 38mm 28 CFM 230V (added 03/11/04)

2

53.2200.0006

4

EA

NUT, 6-32 KEPS SS

3

53.6558.0001

4

EA

SCREW, 6-32 X 3/8" PPZ

4

55.7016.0001

1

EA

FAN GUARD, 80MM NICKEL PLATED STEEL WIRE

1

2

(x4)

3

(x4)

4

Summary of Contents for VL3000

Page 1: ......

Page 13: ...FOREWORD 02 9678 0010 G xi ...

Page 14: ...VARI LITE VL3000 VL3000 Q SERVICE MANUAL xii 02 9678 0010 G ...

Page 74: ...VARI LITE VL3000 VL3000 Q SERVICE MANUAL 56 02 9678 0010 G Notes ...

Page 158: ...VARI LITE VL3000 VL3000 Q SERVICE MANUAL 140 02 9678 0010 G Notes ...

Page 164: ...VARI LITE VL3000 VL3000 Q SERVICE MANUAL 146 02 9678 0010 G Notes ...

Page 216: ...VARI LITE VL3000 VL3000 Q SERVICE MANUAL 198 02 9678 0010 G Notes ...

Page 217: ......