Tape deck

GB 116

VR120

10.

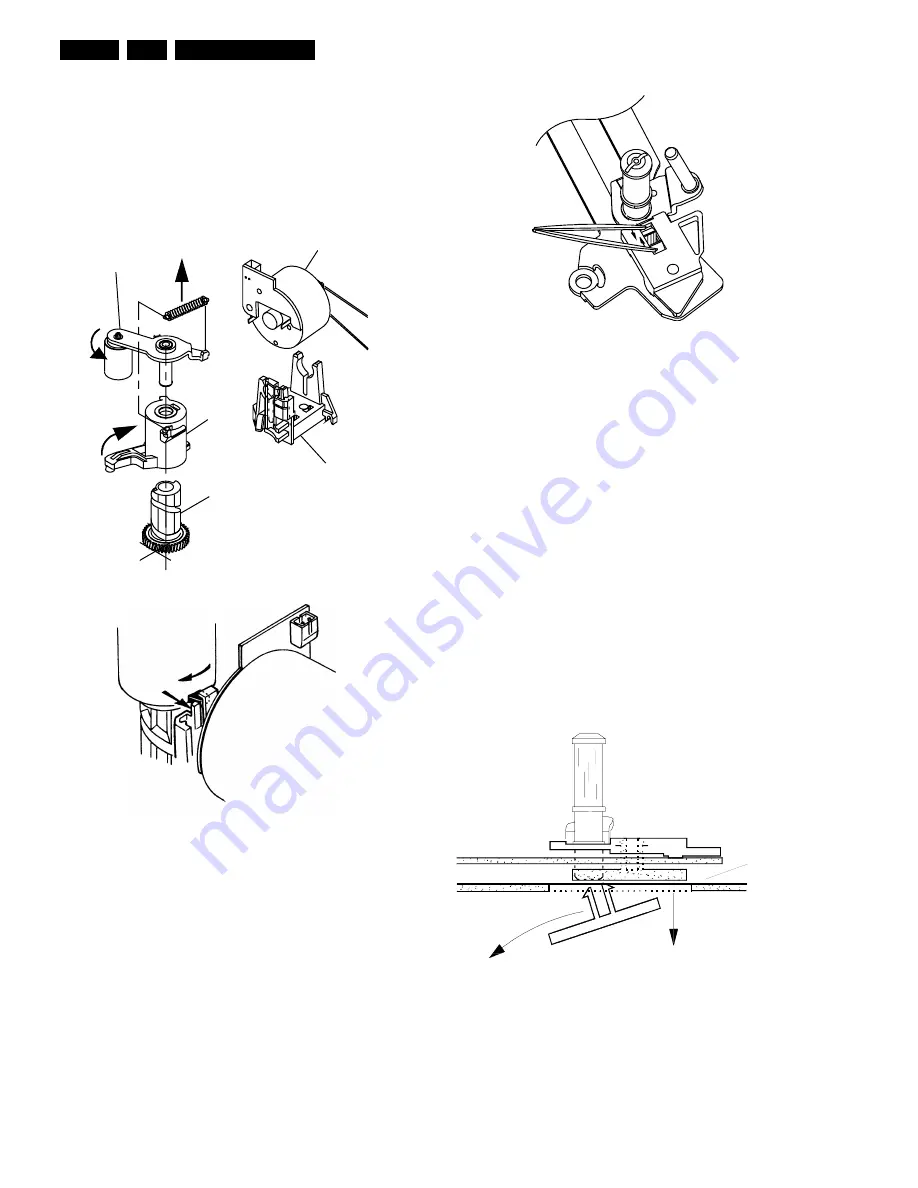

10.1.8 Pressure roller (Pos. 37)

Remove the tape deck.

Unhook and remove the pressure roller tension spring.

Release the pressure roller guide (pos. 41) from the guide in

the threading motor holder by pressing the top of the motor

guide rearwards and rotating the pressure roller guide

assembly clockwise by approximately a quarter of a turn (

see figure 10-7 ). The pressure roller and guide can now be

lifted clear.

Figure 10-7

Ensure that no grease from the pressure roller guide gets to

the capstan or pressure roller.

The reassembly is carried out in reverse order.

10.1.9 Roller unit right (Pos. 26)

Remove the tape deck.

Compress the two snap hooks by means of a pair of tweezers

and remove the roller assy from the roller unit right ( see

figure 10-8 ).

Unhinge the loading arm right fromthe holding plate and push

the latter towards the front of the deck to remove from the

guide (right).

NOTE:

During reassembly ensure the link from 25 is engaged in the

hole of the holder plate 26.

After replacing the roller unit (right), the tape path has to be

checked, and adjusted if necessary.

Figure 10-8

10.1.10 Roller unit left (Pos.23)

Set the drive assy to „Eject“ position.

Unhook the tension arm spring (pos. 11), to avoid the tension

arm spring being pre-loaded.

At the bottom side of the drive assy remove the tension lever

(pos.112).

Compress the two snap hooks by means of a pair of tweezers

and remove the roller assy (A) from the plate (B).

Unhinge the loading arm (left) from the holding plate and

remove the latter downward from the drive assy through the

recess in the chassis ( see figure 10-9 ).

The reassembly is carried out in reverse order.

NOTE :

During reassembly

1.

Place the carriage holding plate in the assembly with the

half-round cutout nearest the rear of the deck.

2.

When the loading arm is refitted ensure the pin on the

underside of 23 is through the link of 24B.

After replacing the roller unit (left) the tape path has to be

checked ( see division 10.2.1 Tape path), and adjusted if

necessary.

Figure 10-9

37

38

40

41

46

pair of

tweezers

A

B

Summary of Contents for VR570

Page 12: ...Direction for use GB 12 VR120 3 3 Direction for use RT111 RT116 RT112 RT114 RT123 RT121 RT128 ...

Page 15: ...Direction for use GB 15 VR120 3 SAT VR870L VR870CC VR720 Set width 435 mm ...

Page 56: ...Service modes Repair tips GB 56 VR120 5 Engineer s remarks ...

Page 79: ...Circuit diagrams and PWB layouts Wiring diagram 79 VR120 7 7 16 Wiring Diagram Motherboard ...

Page 81: ...Circuit diagrams and PWB layouts Wiring diagram 81 VR120 7 Engineer s remarks ...

Page 82: ...82 VR120 7 Circuit diagrams and PWB layouts Wiring diagram Engineer s remarks ...

Page 83: ...Circuit diagrams and PWB layouts Wiring diagram 83 VR120 7 7 18 Mother board component side ...

Page 119: ...Tape deck GB 119 VR120 10 ...

Page 123: ...Tape deck GB 123 VR120 10 Engineer s remarks ...