Tape deck

GB 117

VR120

10.

10.2 Adjustments

Adjustments must not be made in the service position.

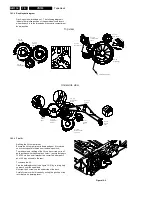

10.2.1 Tape path

Figure 10-10

Roller left unit/roller unit right

Preparation:

Connect one input of a dual trace oscilloscope to observe the

tape sync pulse CTL. The other input (DC coupled) to

observe the tracking information TRIV.

Trigger the oscilloscope externally on the head pulse HP1

(“SWIN”).

Playback the black and white section of the alignment test

tape.

Set the deck in the condition where the video heads are

running along the upper edge of the tracks only by:

•

Call the service test program (see chapter 5.2 Service

test program).

•

Activate manual tracking (service test program step 03)

and watch the tape sync pulse move to the left in relation

to the TRIV signal.

•

Note the extreme left hand position reached by the sync

pulse, repeat as necessary.

•

Stop the movement of the pulse when the TRIV signal

reduces to 1/2 to 2/3 maximum amplitude by pressing the

normal play button. A noisy picture (disturbances) is

visible on the TV set and the CTL pulse should be to the

left of the display.

The recorder will hold this position until the service test

program step 03 is left.

This condition works only if X-distance is adjusted.

Figure 10-11

Adjustment:

Adjust the left and right roller units to make the tracking signal

TRIV straight and flat as possible ( see figure 10-11 ).

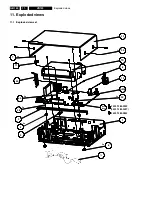

A/C Combi head

Tilt angle adjustment

Set the drive to feature mode (e.g. +7)

Adjustment :

By means of the tilt angle adjusting screw move the tape until

the lower edge just touches the tape guide A1 ( see figure 10-

12 ) the tape must not be distorted at the lower edge (by

pressing onto guide).

Figure 10-12

Adjustment of the azimuth angle and the head height:

Connect an oscilloscope to the linear Audio output.

Play the section of the test cassette with the audio signal 400

Hz.

Adjust for maximum output voltage by means of the height

adjustment screw

Play the section of the test cassette with the audio signal 8

kHz.

Adjust to maximum output voltage by means of the azimuth

adjustment screw ( see figure 10-12 ).

If necessary, repeat this procedure

Check the tilt angle adjustment

If the tape path was completely out of adjustment or if several

components in the tape path have been replaced, it is

possible, that the adjustments described in paragraph “Roller

left unit/roller unit right” and paragraph “A/C Combi head”

have to be repeated several times.

10.2.2 Adjustment of the horizontal distance (x-distance)

Before this adjustment is carried out, insert the test cassette

(start from Eject position). Call the service test program

(tracking value will take up its nominal position) and press the

„play“ button.

Playback the black/white part of the test cassette.)

Display the TRIV signal on an oscilloscope (DC-coupled) and

adjust for maximum voltage by means of the excentric screw

( see figure 10-12 ).

26

31

33/34

23

16

tilt screw

height screw

azimut screw

Tape guide

Capstan wheel

Tape guide

(Reverse lever)

Pressure roller

TAPE

Excenter for

X - distance

Summary of Contents for VR570

Page 12: ...Direction for use GB 12 VR120 3 3 Direction for use RT111 RT116 RT112 RT114 RT123 RT121 RT128 ...

Page 15: ...Direction for use GB 15 VR120 3 SAT VR870L VR870CC VR720 Set width 435 mm ...

Page 56: ...Service modes Repair tips GB 56 VR120 5 Engineer s remarks ...

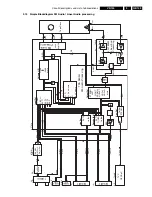

Page 79: ...Circuit diagrams and PWB layouts Wiring diagram 79 VR120 7 7 16 Wiring Diagram Motherboard ...

Page 81: ...Circuit diagrams and PWB layouts Wiring diagram 81 VR120 7 Engineer s remarks ...

Page 82: ...82 VR120 7 Circuit diagrams and PWB layouts Wiring diagram Engineer s remarks ...

Page 83: ...Circuit diagrams and PWB layouts Wiring diagram 83 VR120 7 7 18 Mother board component side ...

Page 119: ...Tape deck GB 119 VR120 10 ...

Page 123: ...Tape deck GB 123 VR120 10 Engineer s remarks ...