Basic information

105555_en_07

PHOENIX CONTACT

7

English

1

Basic information

The portable crimping tool strips conductors in one step and crimps on a ferrule. It crimps

ferrules in square form.

The crimping tool is equipped with an inductive sensor which checks the actual conductor

cross section. If the cross section exceeds or falls below the defined limits, the crimping tool

does not trigger. The LEDs signal when a cross section is detected as being unsuitable.

In exceptional cases, conductors can be processed although they are not suitable. This

leads of crimp results that do not conform with the standards.

1.1

Suitable conductors and ferrules

Suitable conductors

The mobile crimping tool is designed to process fine strand class 5 conductors according to

IEC 60228 with PVC insulation. Only use type H05V-K and H07V-K conductors. Conduc-

tors with very hard insulation such as rubber, silicone, Teflon, and textile insulation are not

suitable.

Avoid processing conductors that are very cold (e.g., directly from an unheated ware-

house). The colder the materials to be processed are, the harder and more resistant they

become. This can lead to increased wear or to mechanical damage.

Please note that the crimping tool can only process a specific conductor cross section. A

significantly deviating conductor cross section is detected and not processed. It may be

possible to process similar conductor cross sections, but this could endanger the electrical

connection. Make sure that conductor cross section and ferrules fit together.

NOTE: To ensure error-free use and the process reliability of the portable crimp-

ing tool, only use the conductors and ferrules described.

Using unsuitable materials may damage the crimping tool and lead to inferior work results.

We recommend that you check the quality of the crimp connections every 5000 cycles or

at the latest after a year.

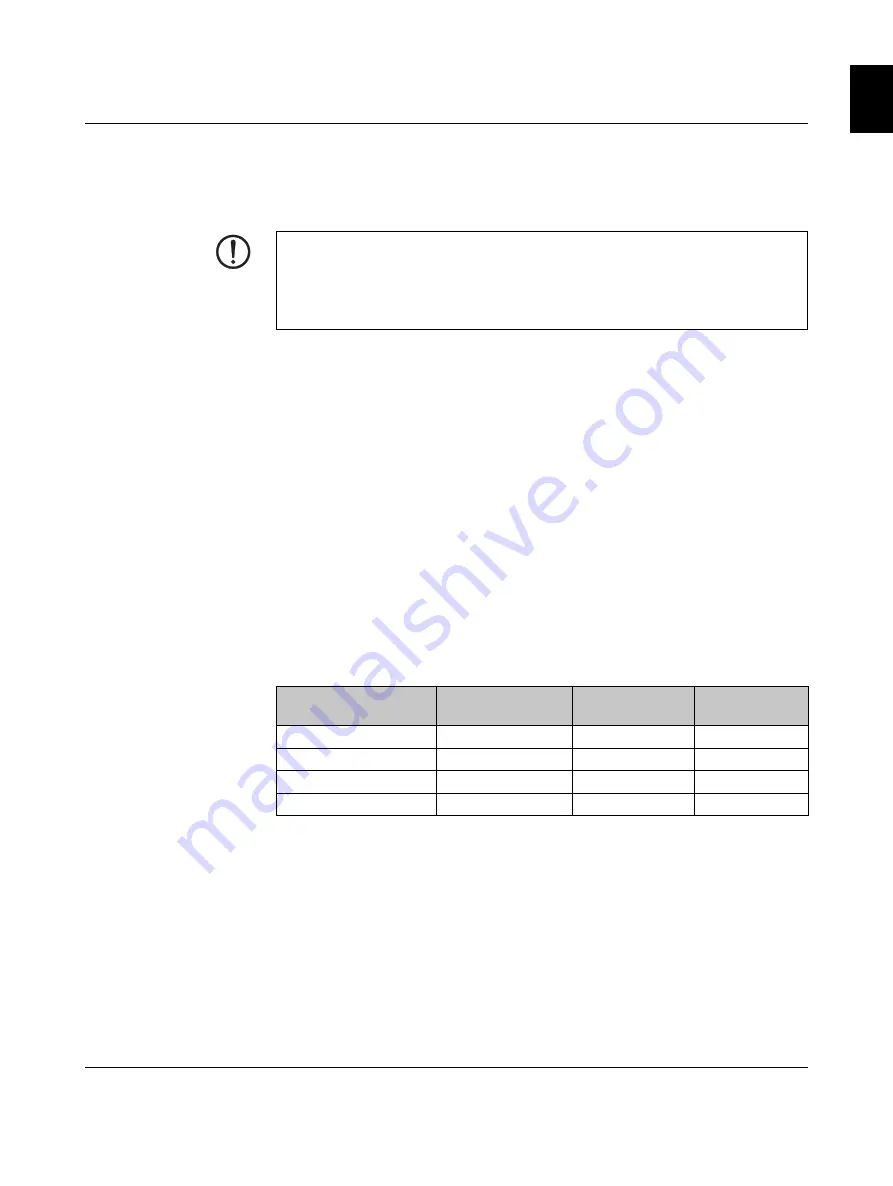

Device type

Conductor cross

section, metric

Outside diame-

ter

Conductor type

CF CRIMPHANDY 0,5

0.5 mm²

1.7 mm ... 2.4 mm

H05V-K

CF CRIMPHANDY 0,75

0.75 mm²

1.9 mm ... 2.6 mm

H05V-K

CF CRIMPHANDY 1,0

1.0 mm²

2.0 mm ... 2.7 mm

H05V-K

CF CRIMPHANDY 1,5

1.5 mm²

2.4 mm ... 3.1 mm

H07V-K

Summary of Contents for 1212463

Page 2: ......

Page 36: ...CF CRIMPHANDY 36 PHOENIX CONTACT 105555_en_07 ...