27

6

Cleaning

6.2 Cleaning the Printhead

!

Attention!

Printhead can be damaged!

Do not use sharp or hard objects to clean the printhead.

Do not touch protective glass layer of the printhead.

!

Attention!

Risk of injury from the hot printhead line.

Ensure that the printhead has cooled down before starting

cleaning.

1

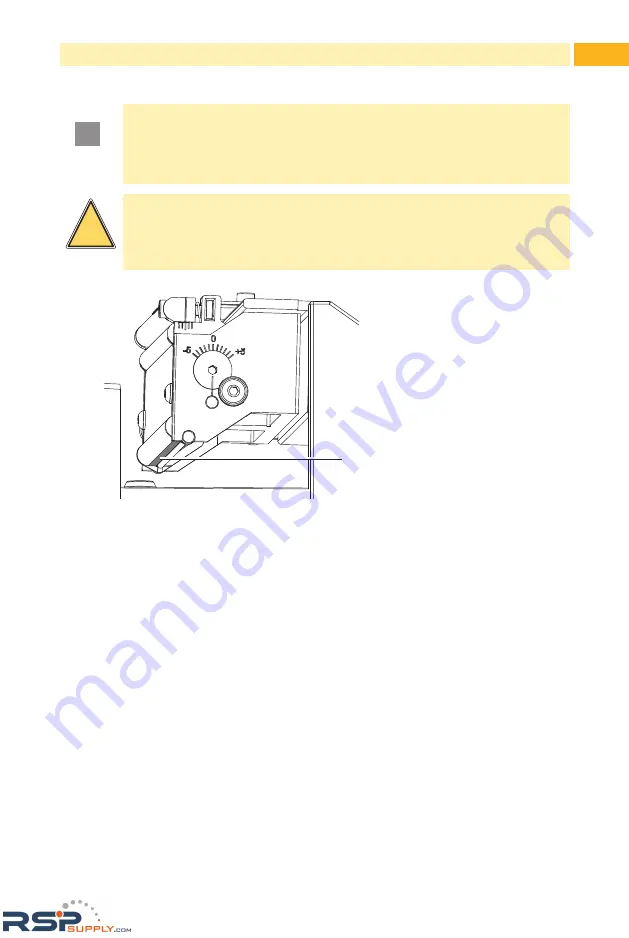

Fig. 17

Printhead line

1. Remove magazine, material and transfer ribbon from the printer.

2. Clean printhead line (1) with a felt stick (CLEANING STICK, Part No.:

5146698) soaked in rubbing alcohol.

3. Allow printhead to dry for 2–3 minutes before commencing printing.

RSPSupply - 1-888-532-2706 - www.RSPSupply.com

http://www.RSPSupply.com/p-11066-Phoenix-Contact-5146464-THERMOMARK-Card-Printer.aspx