Belt Adjustment

CAUTION

: Disconnect all electrical power to the cooler

and insure that belt is not rotating before adjusting belt

tension. Do not adjust belt tension by changing diameter

of adjustable sheave. Adjust belt tension only by adjusting

motor bracket.

Correct belt tension and alignment

is important, proper setup reduces

power consumption and prolongs

life of belt and motor. When

installing or adjusting belt, loosen

the motor adjustment bolts and

adjust to proper tension for each

model as listed. Do not tighten belt

by adjusting motor pulley.

Adjust Motor Pulley

When the cooler is connected to extended ductwork, the cooler

capacity and motor amperage may decrease due to the increased

duct resistance. The adjustable motor pulley is to be used ONLY to

return the cooler motor to it's maximum allowable amperage and

should not be readjusted except for this purpose.

CAUTION:

Do not exceed the maximum motor

amperage (FLA) stamped on the motor specification plate

or motor can be overloaded, damaging motor.

Check amperage with all doors, windows and exhaust

vents open and/or all relief systems operating.

Improper pulley adjustment will overload and severely

damage motor windings (this damage will NOT be covered

under warranty). Only qualified persons with proper

electrical equipment and knowledge should adjust

variable pitch sheaves.

CAUTION:

Never operate unit with access panels

removed. This will result in an overloaded condition and

may damage the blower motor.

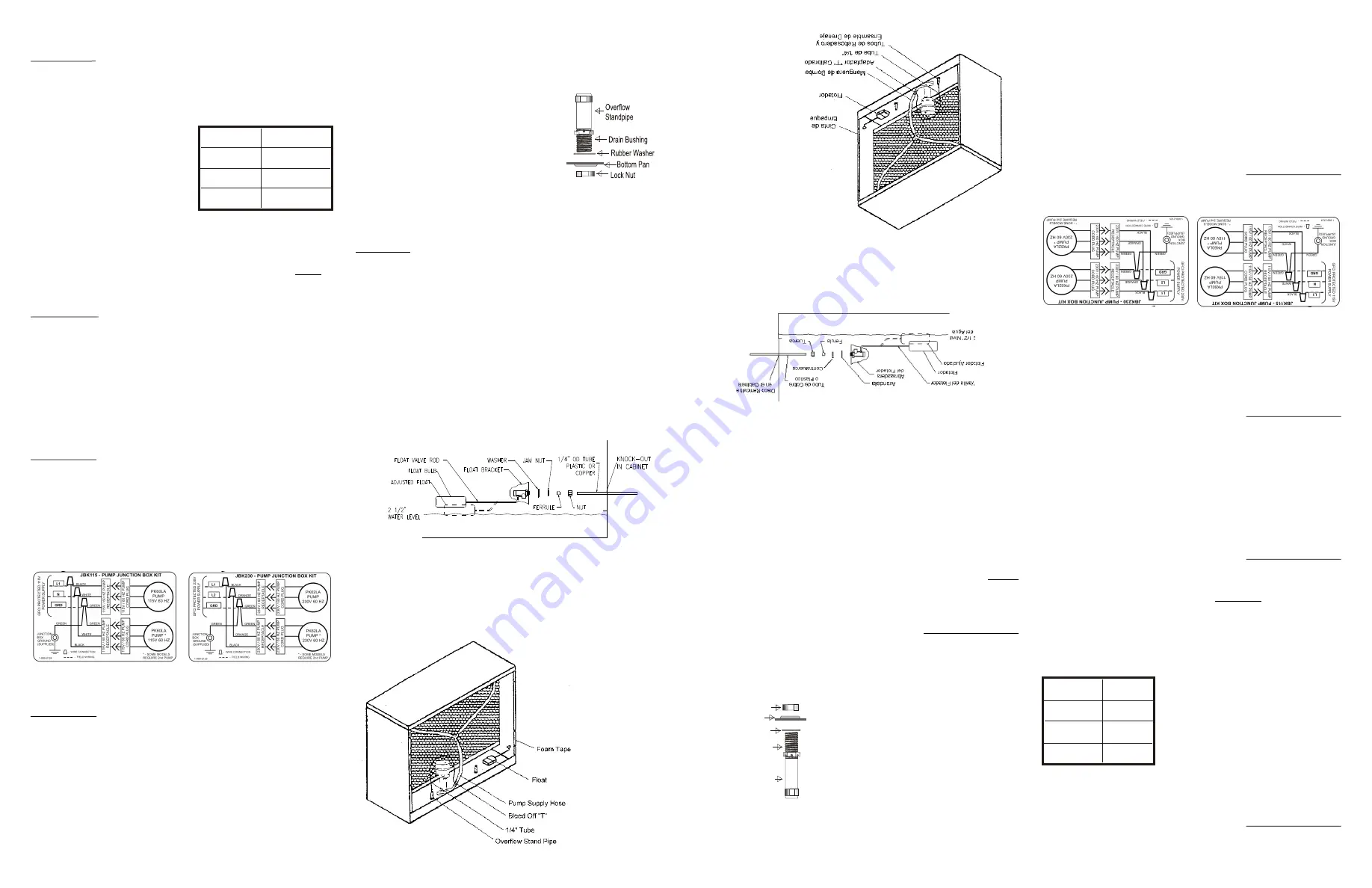

Pump Junction Box

Recirculating Pump

CAUTION:

Do not allow pump to fall over and become

submerged; water will damage pump motor.

Recirculating pump(s) are necessary for Industrial / Commercial

cooler operation. Use pump kit number PK60LA for 115V applications

or PK62LA for 230V applications.

Mount pump junction box assembly (JBK115 for 115V pumps or

JBK230 for 230V pumps) in the location shown on page 7 for your

model. Connect pump receptacle wiring inside junction box to the

GFCI protected pump power supply wiring as shown in appropriate

wiring diagram (label attached to junction box, Figure 3).

Locate and install pump(s) in the location shown on page 7 for your

model. Plug pump cord(s) into junction box receptacle(s) and make

sure that plug is fully inserted. Place pump cord(s) into wire retainer

clips as shown (page 7), insuring that cord(s) does not touch the water

in the bottom pan or contact the wet pads.

Fig. 3

Fig. 4

Fig. 6

Motor Hp Belt Tension

¾

, 1, 1

½

, 2 25 lbs

3, 5 35 lbs

7

½

, 10 40 lbs

4 UL Classified Aerocool Industrial / Commercial Evaporative Cooler Use and Care Manual

Fig. 5

Install Overflow Standpipe / Drain Line

Install overflow drain bushing in bottom of cooler as follows:

Slide rubber washer over drain bushing.

Push drain bushing through bottom of

cooler, assemble and tighten lock nut.

Screw plastic overflow standpipe into the

drain bushing and tighten snugly (hand

tight) to prevent leakage.

Connect a suitable drain line (copper /

PVC / garden hose) to drain bushing.

Never drain water onto a roof; mineral

build-up or damage to roof may occur.

NOTE: Drain water in accordance with local plumbing codes.

Connect Water Supply

CAUTION: All plumbing installations must comply with

local building and safety codes, and must be performed

by qualified personnel only.

NOTE: Coolers should not be connected to “soft” water systems. Soft

water will accelerate corrosion and decrease the effective life of pads

and cooler cabinet. Connect water line as follows:

A water supply valve should be installed at a convenient location,

to allow the water supply to be turned on and off for servicing or

winterizing. Minimum 3/8 diameter tubing should be used to

provide water to the cooler, larger tubing is recommended if the

distance from the valve to the cooler is greater than 100 feet, then

reduced to 3/8” at the unit.

Install float valve in the bracket provided

.

Connect tubing from water supply to float valve. Place

compression nut and ferrule over end of tubing, insert tube into

float valve then tighten compression nut to secure.

Install Bleed-off

To minimize mineral scale “build-up”use the included bleed-off

assembly. Remove the cap from the bleed-off tee; insert the black

tubing and route the tubing through standpipe opening into the drain

line

bove the water level.

(see Figure 5)

(see Figure 6). To prevent siphoning of the water, make sure that

the bleed-off tee is a

In

sta

le

b

uje

d

e d

re

na

je

y

re

bo

sa

de

ro

In

sta

le

e

l b

uje

d

e r

eb

os

ad

ero

e

n e

l fo

nd

o d

el e

nfr

ia

do

r:

De

slic

e la

a

ra

nd

ela

d

e h

ule

e

n e

l b

uje

.

In

se

rte

e

l b

uje

e

n e

l a

gu

je

ro

d

el

fo

nd

o,

y

ap

rie

te

la

tu

erc

a.

Ato

rn

ille

e

l t

ub

o d

e r

eb

os

ad

ero

d

e p

lá

sti

co

al

bu

je

y

a

pri

éte

lo

lig

era

me

nte

(a

pre

ta

do

co

n la

m

an

o)

pa

ra

p

re

ve

nir

fu

ga

s.

Co

ne

cte

a

u

na

lí

ne

a a

de

cu

ad

a d

e d

re

na

je

(c

ob

re

/

P

VC

/

ma

ng

ue

ra

d

e ja

rd

ín

) a

l b

uje

de

d

re

na

je

.

Nu

nc

a

dre

ne

e

l

ag

ua

e

n

el

te

ch

o;

min

era

le

s s

e a

cu

mu

la

n o

d

añ

os

a

l

te

ch

o p

ue

de

n o

cu

rri

r.

NO

TA

: D

re

ne

e

l a

gu

a d

e a

cu

erd

o c

on

lo

s c

ód

ig

os

lo

ca

le

s d

e p

lo

me

ría

.

Co

ne

cte

e

l S

um

in

is

tro

d

e A

gu

a

PR

EC

AU

CIO

N:

T

od

as

la

s

in

sta

la

cio

ne

s

de

p

lo

me

ría

tie

ne

n q

ue

c

um

pli

r c

on

lo

s c

ód

ig

os

d

e e

dif

ic

ar

y r

eg

la

s d

e

se

gu

rid

ad

, y

ll

ev

ad

as

a

c

ab

o p

or

pe

rs

on

al

co

mp

ete

nte

so

la

me

nte

.

NO

TA

: L

os

e

nfr

ia

do

re

s n

o s

e d

eb

en

c

on

ec

ta

r a

s

is

te

ma

s d

e a

gu

a

“b

la

nd

a”.

A

gu

a b

la

nd

a a

ce

le

ra

la

c

orr

os

ió

n y

re

du

ce

la

v

id

a e

fe

cti

va

d

e

lo

s f

ilt

ro

s y

g

ab

in

ete

. C

on

ec

te

e

l s

um

in

is

tro

d

e a

gu

a a

l e

nfr

ia

do

r c

om

o

sig

ue

:

La

v

álv

ula

d

e s

um

in

is

tro

d

e a

gu

a p

od

ría

in

sta

la

rs

e e

n u

n s

iti

o

co

nv

en

ie

nte

,

pa

ra

p

erm

iti

r

ab

rir

y

c

err

ar

pa

ra

d

ar

se

rv

ic

io

o

ap

ag

ad

o d

e in

vie

rn

o.

Un

tu

bo

c

on

u

n m

ín

im

o d

e 3

/8

” s

e d

eb

e u

sa

r

pa

ra

e

l s

um

in

is

tro

d

e a

gu

a h

ac

ia

e

l e

nfr

ia

do

r, U

n t

ub

o m

ás

g

ra

nd

e

se

d

eb

e u

sa

r s

i la

d

is

ta

nc

ia

e

s m

ay

or

de

1

00

p

ie

s y

re

du

cid

a a

3

/8

”

en

la

e

ntr

ad

a d

e la

u

nid

ad

.

In

sta

le

la

v

álv

ula

d

el

flo

ta

do

r e

n l

a a

bra

za

de

ra

p

ro

ve

íd

a (

vé

as

e

Fig

ura

5

)

Co

ne

cte

u

n tu

bo

d

el s

um

in

is

tro

d

e a

gu

a a

l fl

ota

do

r. P

on

ga

la

tu

erc

a

de

c

om

pre

sió

n y

la

fé

ru

la

s

ob

re

e

l e

xtr

em

o d

el t

ub

o,

in

se

rte

e

l t

ub

o

en

la

v

álv

ula

y

a

pri

éte

lo

la

tu

erc

a d

e c

om

pre

sió

n b

ie

n.

I

ns

ta

le

e

l s

an

gra

do

Pa

ra

m

in

im

iz

ar

la

“a

cu

mu

la

ció

n d

e s

arr

o”

us

e l

a e

ns

am

bla

du

ra

d

e

sa

ng

ría

in

clu

id

a.

Re

mu

ev

a e

l t

ap

ón

d

el

ad

ap

ta

do

r “

T”

e i

ns

ert

e t

ub

o

ne

gro

y

g

uíe

lo

a

tr

av

és

d

el t

ub

o d

e r

eb

os

ad

ero

. P

ara

p

re

ve

nir

s

ifó

na

je

de

l a

gu

a,

as

eg

ure

q

ue

la

“T

” d

el

sa

ng

ra

do

e

sté

a

rri

ba

d

el

niv

el

de

l

ag

ua

.

Aju

ste

d

e b

an

da

PR

EC

AU

CIO

N:

D

es

co

ne

cte

to

da

la

c

orr

ie

nte

e

lé

ctr

ic

a

ha

cia

e

l e

nfr

ia

do

r y

a

se

gú

re

se

q

ue

la

b

an

da

n

o e

ste

d

an

do

vu

elt

as

a

nte

s d

e a

ju

sta

r l

a t

en

sió

n.

No

a

ju

ste

la

b

an

da

ca

mb

ia

nd

o e

l d

iá

me

tro

d

e l

a p

ole

a a

ju

sta

ble

. A

ju

ste

la

te

ns

ió

n s

ola

me

nte

a

ju

sta

nd

o e

n lo

s r

ie

le

s d

e la

b

as

e.

T en

sió

n d

e la

b

an

da

y

a

lin

ea

ció

n c

orr

ec

ta

es

im

po

rta

nte

, p

ro

pia

in

sta

la

ció

n r

ed

uc

e

co

ns

um

o d

e e

ne

rg

ía

y

e

xti

en

de

la

v

id

a d

e

la

b

an

da

y

la

d

el m

oto

r. C

ua

nd

o s

e in

sta

le

o s

e a

ju

ste

la

b

an

da

, a

flo

je

lo

s to

rn

illo

s d

e

aju

ste

d

el

mo

to

r

y

aju

ste

a

la

te

ns

ió

n

ap

ro

pia

da

p

ara

c

ad

a m

od

elo

c

om

o e

sta

lis

ta

do

a

ba

jo

.

No

a

ju

ste

la

b

an

da

aju

sta

nd

o la

p

ole

a d

el m

oto

r.

Aju

ste

d

e p

ole

a d

el

mo

to

r

Cu

an

do

e

l

en

fri

ad

or

es

ta

c

on

ec

ta

do

a

c

on

du

cto

s

ex

te

nd

id

os

,

la

ca

pa

cid

ad

d

el

en

fri

ad

or

y e

l a

mp

era

je

d

el

mo

to

r d

is

min

uy

e d

eb

id

o a

l

au

me

nto

e

n la

re

sis

te

nc

ia

d

el c

on

du

cto

. L

a p

ole

a a

ju

sta

ble

d

el m

oto

r

es

p

ara

s

er

us

ad

a s

ola

me

nte

p

ara

re

gre

sa

r e

l e

nfr

ia

do

r y

e

l m

oto

r a

s

u

má

xim

a c

ap

ac

id

ad

p

erm

iti

da

y

n

o s

e d

eb

e r

ea

ju

sta

r e

xc

ep

to

p

ara

e

ste

pro

pó

sit

o.

PR

EC

AU

CIO

N:

No

e

xc

ed

a

el

má

xim

o

am

pe

ra

je

d

el

mo

to

r (

FL

A)

es

ta

mp

ad

o e

n l

a p

la

ca

d

e e

sp

ec

ifi

ca

cio

ne

s

de

l m

oto

r o

e

l m

oto

r s

e p

ue

de

s

ob

re

ca

rg

ar

da

ñá

nd

olo

.

Re

vis

e

el

am

pe

ra

je

c

on

to

da

s

la

s

pu

ert

as

,

ve

nta

na

s

ve

nti

la

cio

ne

s y

/o

to

do

s lo

s s

is

te

ma

s d

e r

eli

ev

e o

pe

ra

nd

o.

Aju

ste

im

pro

pio

d

e

la

p

ole

a

mo

tri

z

so

bre

ca

rg

a

y

da

ña

se

ve

ra

me

nte

lo

s d

ev

an

ad

os

d

el

mo

to

r (

es

te

d

añ

o n

o e

s

cu

bie

rto

b

ajo

la

g

ar

an

tía

)

So

la

me

nte

p

er

so

na

s

ca

pa

cit

ad

as

c

on

e

l

eq

uip

o

ap

ro

pia

do

y

c

on

oc

im

ie

nto

de

be

n a

ju

sta

r p

ole

as

a

ju

sta

ble

s.

PR

EC

AU

CIO

N:

Nu

nc

a o

pe

re

la

u

nid

ad

s

in

lo

s p

an

ale

s

de

a

cc

es

o.

Es

to

re

su

lta

ría

e

n c

on

dic

ió

n d

e s

ob

re

ca

rg

a y

po

drí

a d

añ

ar

el m

oto

r d

e la

tu

rb

in

a.

Ca

ja

d

e e

mp

alm

e b

om

ba

Mo

nte

la

c

aja

d

e e

mp

alm

e d

e l

a b

om

ba

(J

BK

11

5 p

ara

b

om

ba

s d

e

11

5V

o

J

BK

23

0 p

ara

b

om

ba

s d

e 2

30

V)

en

e

l s

iti

o in

dic

ad

o e

n p

ág

in

a 7

pa

ra

s

u m

od

elo

. C

on

ec

te

e

l a

la

mb

ra

do

d

el

re

ce

ptá

cu

lo

d

e l

a b

om

ba

en

la

c

aja

d

e e

mp

alm

e a

la

fu

en

te

d

e p

od

er

pa

ra

la

b

om

ba

q

ue

te

ng

a

pro

te

cc

ió

n d

e G

FC

I c

om

o lo

in

dic

a e

l d

ia

gra

ma

d

e a

la

mb

ra

do

(F

ig

. 3

)

Bo

mb

a d

e r

ec

irc

ula

ció

n

PR

EC

AU

CIO

N:

N

o p

erm

ita

q

ue

la

b

om

ba

s

e c

aig

a y

s

e

su

me

rja

; e

l a

gu

a d

añ

a e

l m

oto

r.

La

b

om

ba

(s

) d

e r

ec

irc

ula

ció

n s

on

n

ec

es

ari

as

p

ara

la

o

pe

ra

ció

n d

e lo

s

en

fri

ad

ore

s

In

du

str

ia

le

s

/

Co

me

rc

ia

le

s.

Us

e

el

ju

eg

o

de

b

om

ba

nú

me

ro

P

K6

0L

A p

ara

a

plic

ac

io

ne

s d

e 1

15

V o

P

K6

2L

A p

ara

2

30

V.

Lo

ca

lic

e e

in

sta

le

la

b

om

ba

(s

) e

n e

l s

iti

o in

dic

ad

o e

n p

ág

in

a 7

p

ara

s

u

mo

de

lo

. E

nc

hu

fe

e

l c

ord

ón

(e

s)

en

é

l(l

os

) r

ec

ep

tá

cu

lo

d

e l

a c

aja

d

e

em

pa

lm

e y

a

se

gu

re

q

ue

e

sté

b

ie

n e

nc

hu

fa

do

. A

co

mo

de

lo

s c

ord

on

es

de

la

b

om

ba

e

n la

s a

bra

za

de

ra

s p

ara

a

la

mb

re

in

dic

ad

o e

n (

pa

gin

a 7

)

as

eg

úre

se

q

ue

e

l

co

rd

ón

(e

s)

no

to

qu

e

el

ag

ua

e

n

el

fo

nd

o

de

l

de

pó

sit

o o

to

qu

en

lo

s fi

ltr

os

h

úm

ed

os

.

M

oto

r C

F

Ban

da

Ten

sió

n

¾

, 1

, 1

½

, 2

2

5 lb

s

3,

5

3

5 lb

s

7

½

, 1

0

40

lb

s

Fig

.3

4

U

L C

las

ific

ado

A

ero

coo

l In

dus

tria

l /

Com

erc

ial

E

nfr

iad

or

Eva

por

ativ

o M

anu

al d

e U

so

y C

uid

ado

Buj

e d

e D

ren

aje

Tu

bo

d

e

Re

bo

sa

de

r

Ara

nde

la

de

hul

e

Fon

do

Tue

rca

Fig

ura

4

Fig

ura

5

Fig

. 6