UL Classified Industrial / Commercial Evaporative Cooler Use and Care Manual 7

Legend

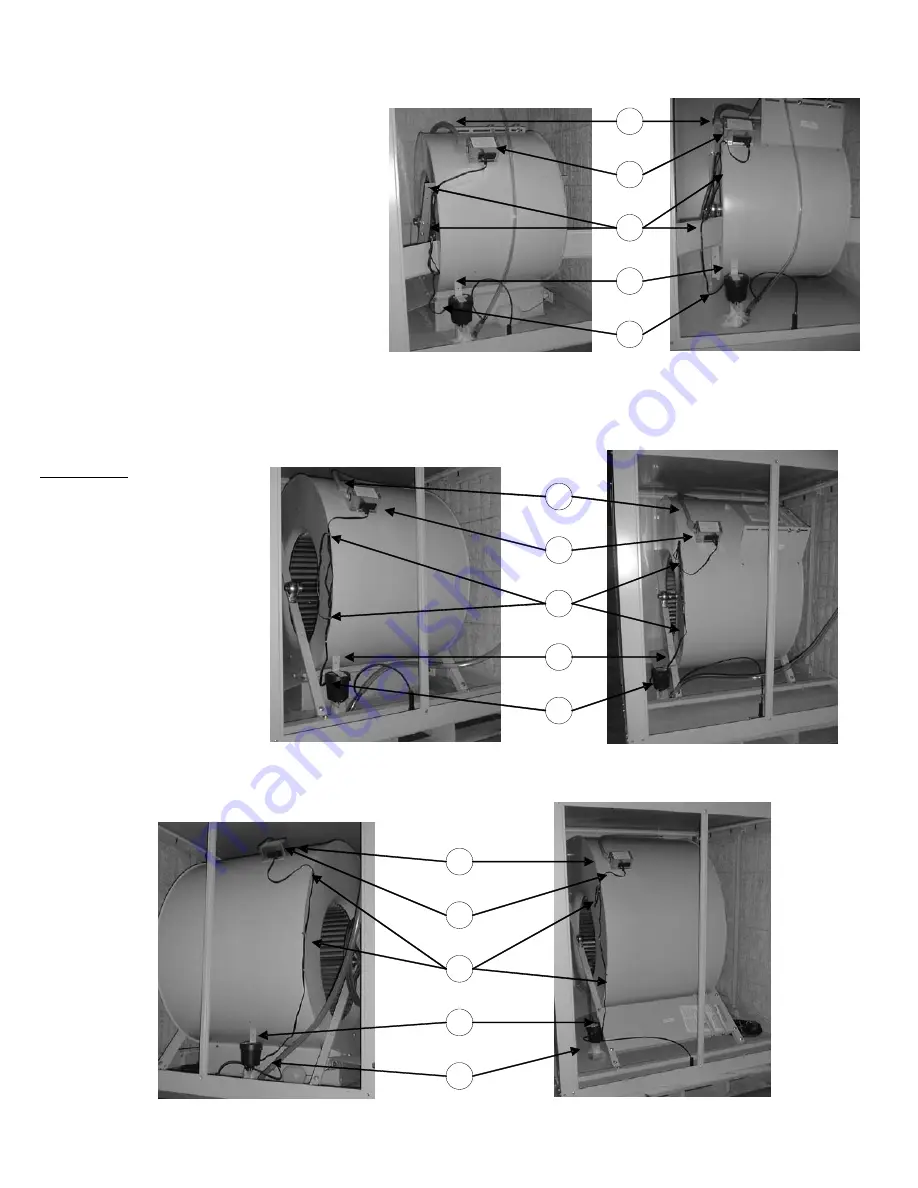

1.

Pump Cord Clips (approximate locations).

2.

Pump junction box assembly (JBK115 or

JBK230). Using “Locate J-box here” label as a

guide, position and install in indicated

location using holes in junction box flanges

as guides to locate self-drilling screws.

3.

Conduit and wiring from junction box to GFCI

protected pump electrical supply (circuit

must match pump voltage).

4.

Pump location and mounting procedure:

!

Position pump as shown for your specific

model, make sure pump sits flat on bottom.

Bend bracket as required to conform to the

mounting surface.

!

Using slotted holes in bracket as a guide,

mark and drill two 1/8” holes.

!

Secure pump with two #10 screws

(provided).

5. Route pump cord as shown, making sure cord

does touch water or wet pads and cannot be

pulled into the moving blower wheel or drive

assembly. Leave sufficient slack in cord to

create a “drip” loop just before the cord enters

pump housing.

CAUTION:

Route pump cord

through wire clips

making sure cord

does not touch

water in either the

bottom pan or the

pads in the frame.

3

2

1

4

5

3

2

1

4

5

3

2

1

4

5

D8801

H8801

D1425

H1425

D2231A

H2231