INTRODUCTION

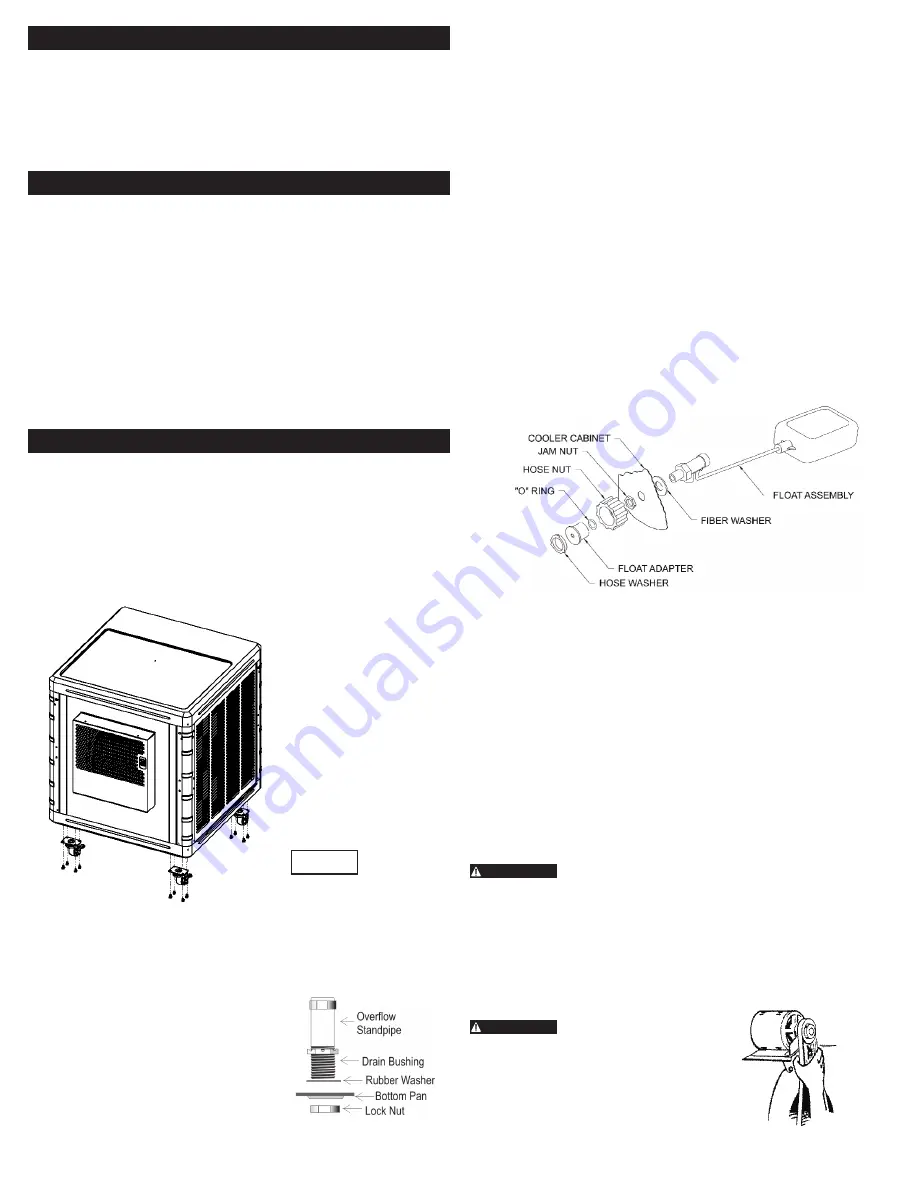

Install float valve and hose adapter

Attach the float valve to the cabinet as shown below. The garden

hose adapter attaches to the brass inlet fitting on the float valve.

NOTE:

verify that the hose washers are correctly in place.

Water connection and float adjustment

Move cooler to desired location (this should be a level area for proper

operation of the cooler).

1. Locate a knock-out in the bottom of any of the four corner posts.

2. Connect to water supply using a commercial grade of water hose

(not supplied with cooler, obtained separately) to the adapter on

the float valve and turn water on. CAUTION: water inlet pressure

should be limited to a maximum of 65 PSI to avoid rupturing the

water hose. If pressure exceeds this value, an inline pressure

regulator should be installed (obtainable from a local plumbing or

hardware store).

3. Check that all connections are tight by visually inspecting hose,

float valve, etc. for leakage.

4. Set float valve for a water depth of 2-1/2". The float is adjusted by

lightly bending the float rod.

Your evaporative air cooler was thoroughly tested and inspected

before leaving the factory. This is your guide to economical, trouble

free comfort cooling over the years with reasonable care and regular

maintenance. Failure to follow these instructions may damage your

cooler, impair its operation and/or void the warranty

Read it carefully.

SET UP FOR ROLL-AROUND USE

• Open parts box & remove casters from parts bag. Assemble each

caster (Fig.1) per caster plate using supplied 1/4-20 nuts & carriage

bolts.

• Place casters w/ brakes on the front of the unit, and the casters

without the brakes should be mounted on the back of the cooler.

Use 4 of the 1/4-20 bolts from the parts bag to secure all 4 of the

casters to their respective caster plates. Apply brakes before lifting

cooler upright to complete assembly.

2 Master Blaster Use and Care Manual

PREPARATION FOR ASSEMBLY

Remove the pad frames by slightly lifting the pad frame from the

bottom, pull outwards until clear of cabinet bottom pan, then

downwards until frame clears cabinet top. Remove the following

items from the cooler:

1. Box containing swivel casters and attachment hardware.

2. Plastic bag containing small parts, float valve, garden hose adapter,

hose nut, hose washer, o-ring.

3. Bag with hose adapter for float valve (roll-around use)

Gather tools required to assemble & install unit

The following tools are required to assemble the unit:

7/16" box or open end wrench

3/8" box or open end wrench

6" crescent wrench

1/4" nut driver

Figure 1

Install Overflow Standpipe / Drain Line

Install overflow drain bushing in bottom of cooler as follows:

• Slide rubber washer over the brass drain

bushing.

• Push drain bushing through bottom of

cooler, assemble and tighten lock nut.

• Screw plastic overflow standpipe into the

drain bushing and tighten snugly (hand

tight) to prevent leakage.

• Where conditions allow for drainage,

connect a drain line (garden hose) to

drain bushing.

Cooler checkout and first time start-up

Congratulations, once you re-install the pad frames, your roll-around

Master Blaster cooler will be complete and ready for use. Please

proceed to the Pre-startup inspection checklist on page 3 before

starting unit for the first time.

Motor and blower wheel check

Check motor mounting to be sure all screws and nuts are tightened

down properly. Rotate blower wheel by hand to see that it moves

freely without rubbing against housing.

Belt Tension Adjustment

CAUTION:

Disconnect all electrical power to the cooler and insure that belt

is not rotating before adjusting belt tension.

Correct belt tension and alignment is important, proper setup reduces

power consumption and prolongs life of belt and motor. Check belt

tension by squeezing belt. Proper tension will allow deflection of ½

to ¾ inch. To increase or decrease belt tension, loosen bolt in slot of

motor support bracket. Adjust belt to proper tension and retighten

bolt.

CAUTION:

Never operate unit with pad frame(s)

and/or air outlet grille removed. This

will result in an overloaded condition

and may damage the motor.