6 Master Blaster Use and Care Manual

TROUBLESHOOTING GUIDE:

Should an obvious problem occur with your cooler consult the following table. If you cannot correct the problem, or if it persists,

contact qualified service personnel.

PROBLEM / SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Water draining from unit

Float valve out of adjustment

Adjust float to 2-1/2" water depth

Float movement obstructed

Free float from obstruction

Float valve non-functional

Replace float assembly

Dry pads

Pump intake clogged

Remove obstruction

Water pump non-functional

Replace water pump

Clogged water line

Locate and free obstruction

Pad trough clogged

Clear debris from trough

Switch non-functional

Replace switch

Wiring non-functional

Repair or replace non-functional wiring

Water turned off to cooler

Turn on water supply

No water

Fill reservoir

Motor does not start or no air

delivery

Electrical power disconnected

Check power receptacle and cord

Belt too loose or too tight

Adjust belt tension

Defective motor

Replace motor

Defective switch

Replace switch

Broken belt

Replace belt

Inadequate air delivery

Insufficient air exhaust

Open windows to increase air flow

Belt too loose

Adjust belt tension or replace if necessary

Pads plugged

Replace pads

Motor cycles on & off

Low voltage

Check voltage

Excessive belt tension

Adjust belt tension

Blower shaft tight or locked

Oil or replace bearings

Bearing dry

Oil bearings

Pad frame(s) or air outlet grille removed

Re-install pad frame(s) or air outlet grille

Noisy operation

Blower rubbing on housing

Reposition wheel

Motor sheave or blower set screws loose

Tighten set screws

Excessive humidity in house

Inadequate exhaust

Open doors and windows to increase ventilation

Musty or unpleasant odor

Stale or stagnant water in cooler

Drain, clean, and flush reservoir

Media pads clogged or mildewed

Replace media pads

Media pads not completely wet before starting

fan motor

Turn pump ON for several minutes prior to starting

cooler

New pads have an odor that goes away after

about 4-8 hours.

Drain reservoir multiple times until odor dissipates

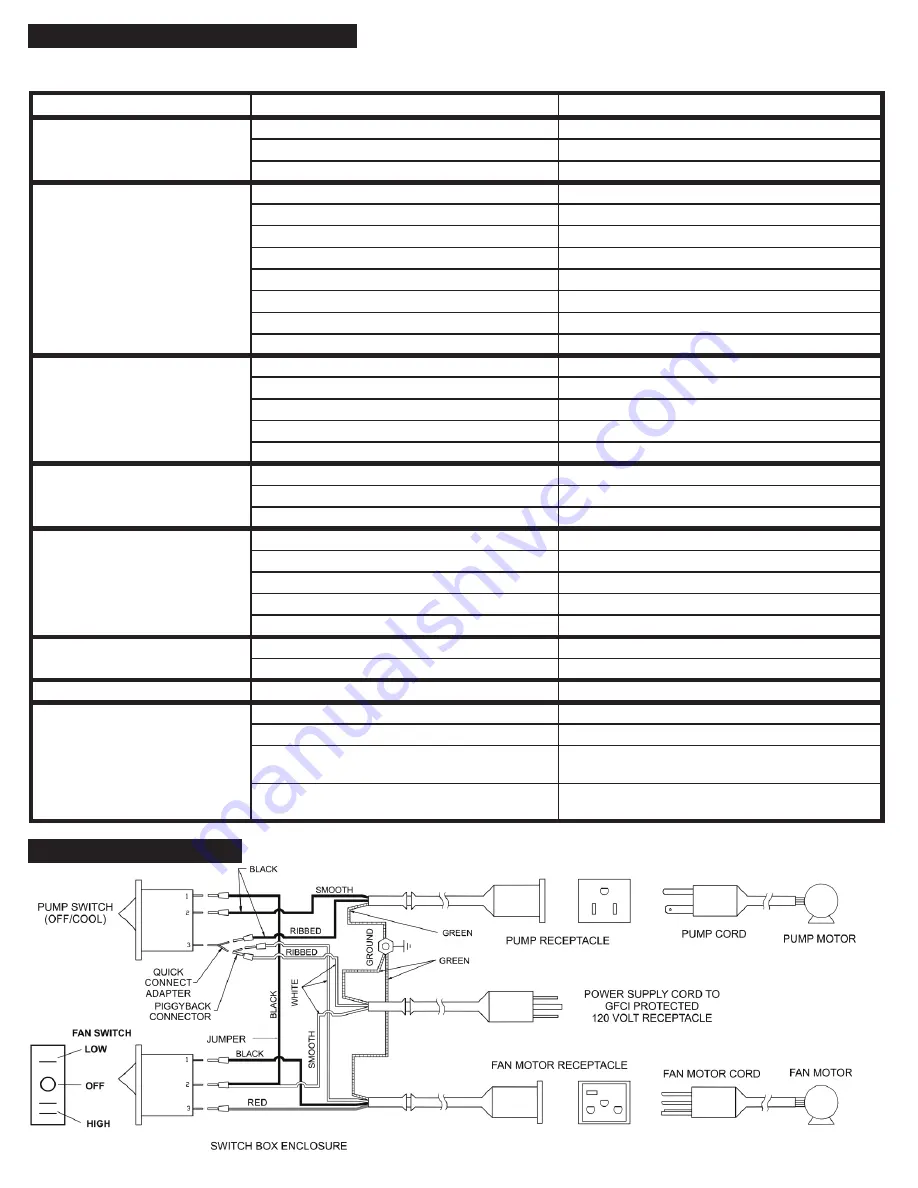

WIRING DIAGRAM