a. Remove inlet (back) grille from cabinet.

b. Remove top pan from cabinet.

c. Remove water distributor cover and tube assembly.

d. Remove pads by tilting slightly forward and carefully

lifting up and out. If passages are clogged or pad is dirty,

hose off inlet face of pad. Light, gentle brushing of the

inlet edges of the pad with a stiff bristle brush (do not use

a wire brush) will not harm the pad and will remove more

stubborn scaling.

e. If necessary, replace with new rigid media pads, available

only from your rigid media dealer. Aspen, expanded paper

or other types of evaporative cooling pads will not work

and will void your warranty.

3. Using a mild detergent, wash dirt and scale from the

inside of the wet section cabinet. Wire brushing is not

recommended. If finish is damaged or rusting is noted,

repair as noted in the “Touch-Up” section. Rinse with

fresh water.

• Reinstall pads, making sure they are positioned correctly

(painted stripe on pad placed to the bottom, facing

outside).

• Reinstall water distributor cover and tube assembly.

• Reinstall top pan to wet section cabinet.

• Reinstall inlet louver panels.

PAGE 6

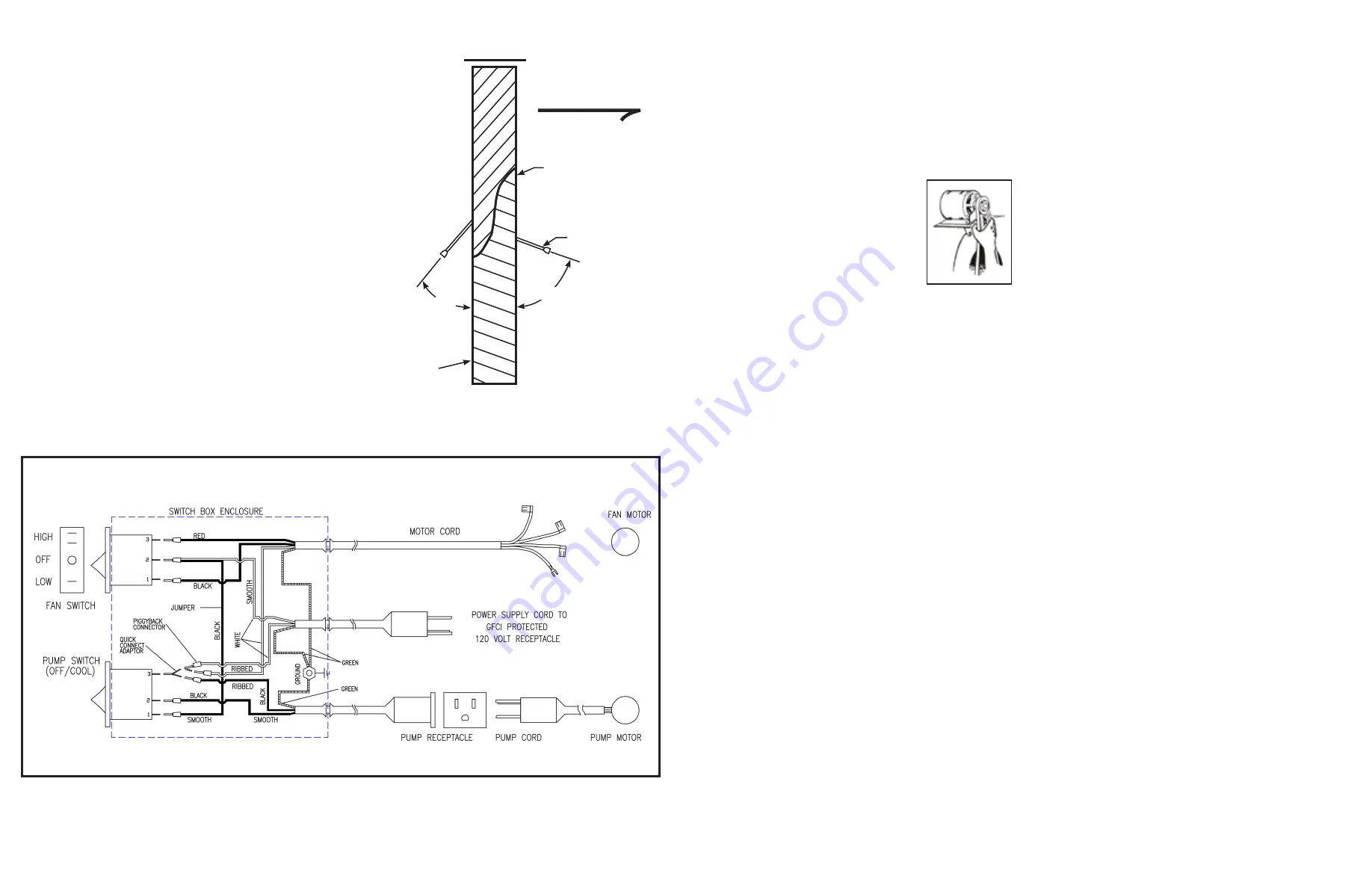

WIRING DIAGRAM

END VIEW

AIR FLOW

THIS SURFACE TO

INSIDE OF UNIT

(TOWARD BLOWER)

PENCIL

SEE SIDE OF PAD

FOR DIRECTION

AL

AIR FLOW

45°

75°

PAGE 3

Motor and fan check

Using ¼ nut driver remove front grille screw as shown in fig-

ure 1. Remove the grille by slightly lifting it from the bottom,

pull outwards until clear of cabinet bottom pan, then down-

wards until frame clears cabinet top. Check motor mounting

to be sure all screws

Belt Adjustment

Correct belt tension and alignment is

important as it cuts power consumption

and prolongs life of belt and motor. When

installing or adjusting belt, loosen the

motor adjustment bolts and adjust for

proper tension. Align belt vertically by

centering motor pulley in-line with

blower pulley. Dot not adjust motor

sheave turns. Adjusting sheave turns

will void warranty.

Electric Power

CAUTION:

• This cooler is designed for connection to 120 volt AC, 60

Hz (cycle) power only. NOTE: Improper voltage will void the

pump and/or motor warranties and may cause serious per-

sonal injury or property damage.

• This cooler must be plugged into a GFCI protected re

-

ceptacle, which has been properly installed in accordance

with all local and national codes. If you are not sure that the

receptacle is GFCI protected, consult with a qualified electri

-

cian.

• This cooler is equipped with a power cord having an

equipment grounding conductor and grounding plug.

DO

NOT

attempt to defeat this safety device by removing the

grounding pin.

Cooler checkout and first time start-up

Congratulations your cooler is complete and ready for use.

Please proceed to Pre-startup inspection checklist on

page 3 before starting unit for the first time.

• Fan, shaft, pulley and motor sheave set bolts/screws are

snug.

• Motor sheave alignment okay; belt tension okay (see page

3 for instructions).

Start-up Checklist

CAUTION: Never operate unit with inlet/outlet grille

removed. This will result in an overloaded condition and

may damage the fan motor. The motor and pump have

an internal automatic thermal overload switch that will

shut the motor and/or the pump off if it overheats! The

motor and/or pump can restart automatically when they

cool down.

To verify and check out the cooler installation on initial start-

up, the following procedure should be followed.

• Push “COOL” switch to ON position (pump on).

• Verify that pump starts and pads are evenly wet.

• Open windows, doors or vents in building.

• Push “FAN” switch to LOW position (low speed on).

• Observe that motor starts and runs. Check high-speed

function by turning “FAN” switch to HIGH (high speed on).

In case of trouble in any of these stages, refer to the

Troubleshooting chart on page 7.

Cabinet Inspection Checklist

After initial start-up and during periodic inspections,

check for and/or observe the following: Refer to the

Troubleshooting Chart on if necessary.

• Leaks from cabinet

• Observe cooler media for uneven wetting

• Confirm water level setting is correct.

• Verify full, even flow in water distribution system.

• Fan / motor rotates freely, no unusual noises.

• Belt condition / tension / alignment.

• Check motor mounting and cabinet hardware.

Extended Shut-down (winterizing)

checklist

Any time the unit will not be used for an extended period:

• Move cooler to the area appropriate to dump water.

Remove brass drain cap as shown in fig 2. Drain all of the

water out of the cooler when not used for prolonged

periods, particularly at the end of the season (winter).

• Unplug the cooler power supply cord and secure it out of

the way on the side of the unit to avoid damage.

GENERAL INSPECTION

Pre-Start-up Inspection Checklist

• Cooler is on a level surface, casters locked to prevent

unnecessary movement (prevent spillage).

• Power supply cord is plugged into a GFCI protected

receptacle; cord is secure from accidental damage.

• Float valve installed.

• Water hose connected securely without leaks. Water

faucet or supply is turned on.

• Float adjusted for proper water level.

• Inlet and outlet grilles correctly installed.

• Pump impeller turns freely. Remove impeller cover

(see page 5 “Cleaning Pump”) and check rotation.

and nuts are tightened down properly.

hand to see that it moves freely withou

Rotate the fan by

ut rubbing against

hand to see that it moves freely without

housing. Reinstall the front grille and sec

rubbing against

cure with the scre

housing. Reinstall the front grille and secure

with the screw.