DUOMAT 9

Installation

79338 4.0

23

Figure 13

Removing the shutters

D

Shutters

E

Fitting mounts

F

Snap-in locking device (for cover)

G

Locking tab on shutter lock

4

Lift the locking tab on the shutter lock (

F

) and slide the shutter lock towards the middle of the

drive. This will open the shutter.

5

Pull firmly on the shutters (

D

) so that they are completely removed from the DUOMAT 9.

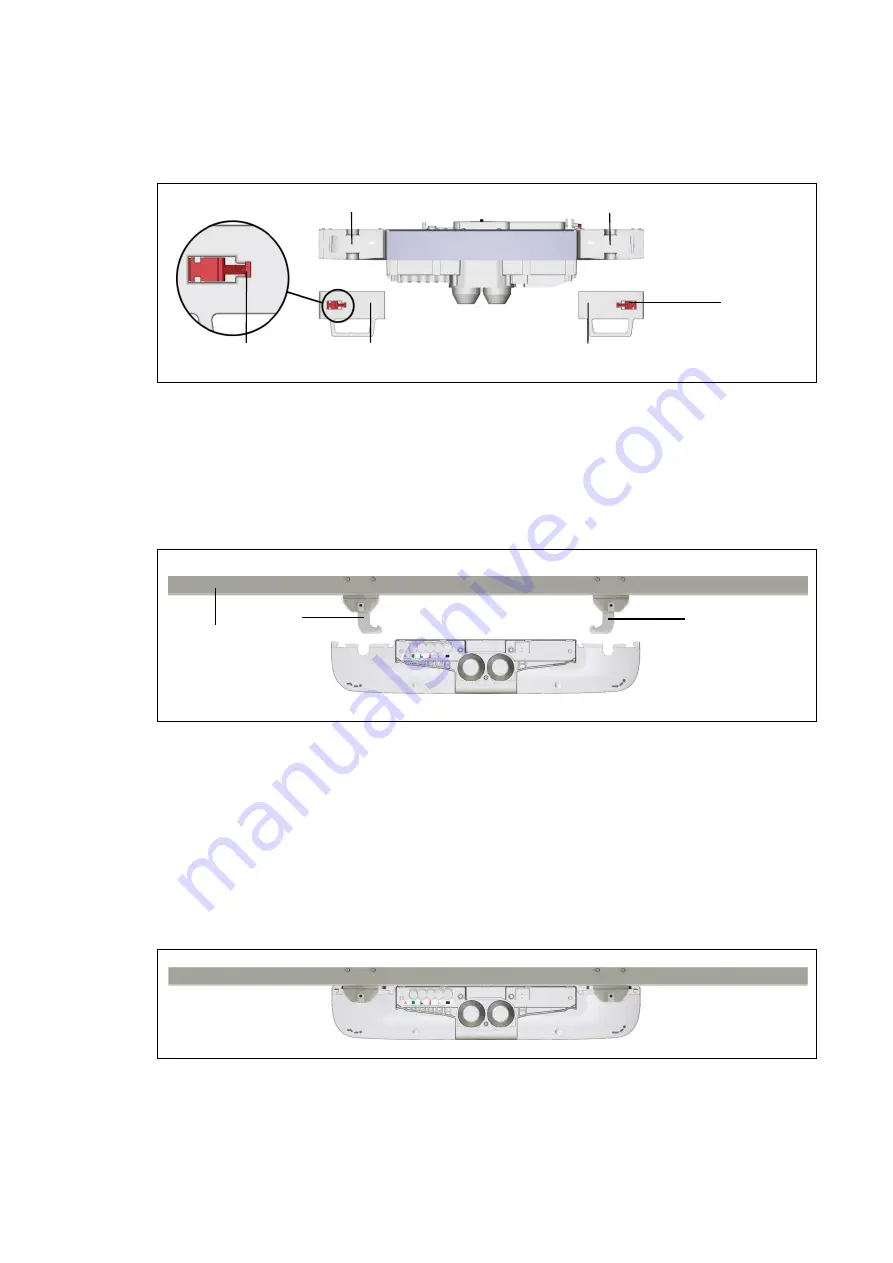

Figure 14

Positioning the double drive on the end product

H

End product

I

Shaft with pivot lever

6

Move the DUOMAT 9 into the proper position within your end product. The slots for the head

and foot ends must be properly aligned with the correct brackets to your end product (

H

) (refer

to the symbols on the DUOMAT 9 in Figure 5).

7

Slide the drive's slots

(E)

on the shaft

(I)

until the drive snaps in.

8

Attach the shutters to the DUOMAT 9. The drive is now firmly attached to your end product.

9

Lock the shutter lock (

F

) so that it locks into position (so that the locking tab (

G

) is in the recess

of the shutter).

Figure 15

Double drive mounted to the end product

D

E

E

F

D

H

I

I

G

Summary of Contents for Dewert Okin DUOMAT 9

Page 1: ...DUOMAT 9 Installation Instructions Translation of the original installation instructions...

Page 2: ......

Page 42: ......

Page 43: ......