https://www.hartmann-electronic.com/

13

Rev. 1.3

Subrack systems LMH0000200, LMH0000312, LMH0000170, and LMH0000240

are delivered with fuse: 5x20mm 250V/6,3A T m. UL/CSA:

Subrack systems LMH0000180 and LMH0000260

are delivered with fuse: 5x20mm 250V/10A T m. UL/CSA

Caution!

The fuse values (6,3A T, 10A T) are only for incoming inspection.

The final values depends on the ready configuration of the completed system,

e.g. number of power supplies.

3.4.2

Grounding/Protective Earthing

The system contains gaskets at the subrack and board level to guard against electromagnetic

interference (EMI). Each of the subrack’s

individual components make contact with the

gaskets and to the PE-stud inside the rear panel.

The guide rails are also fitted with electrostatic discharge (ESD) contacts for each blade and

RTM. These ESD contacts ensure that the boards are fully discharged to prevent static caused

by static as they are plugged into the subrack.

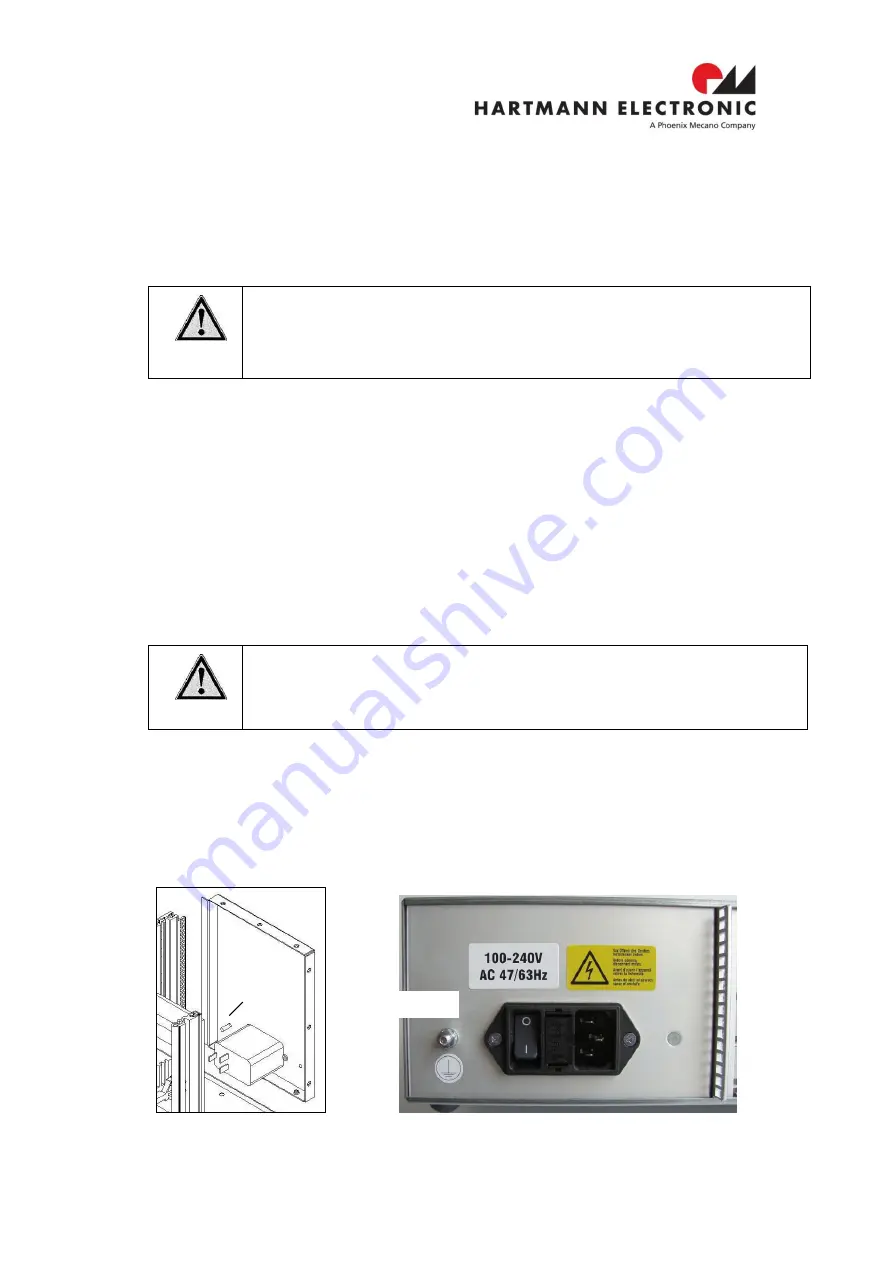

Caution!

The subrack is designed in accordance with protection class1l! lt must therefore be

operated with protective earth/GND connection. Use only a three conductor AC power

cable with a protective earth conductor that meets the IEC safety standards!

There is a 4 mm stud at the rear panel. This stud is only for potential equalization. Grounding

is achieved through the protective earth conductor of the power cable!

Figure 3-15 Protective Earth and Grounding

4mm-Stud

PE-Stud 4mm