9. After the epoxy has fully cured, remove the

masking tape or T-pins used to hold the

stabilizer in place and carefully inspect the glue

joints. Use more epoxy to fill in any gaps that

were not filled previously and clean up the

excess using a paper towel and rubbing alcohol.

INSTALLING THE VERTICAL STABILIZER

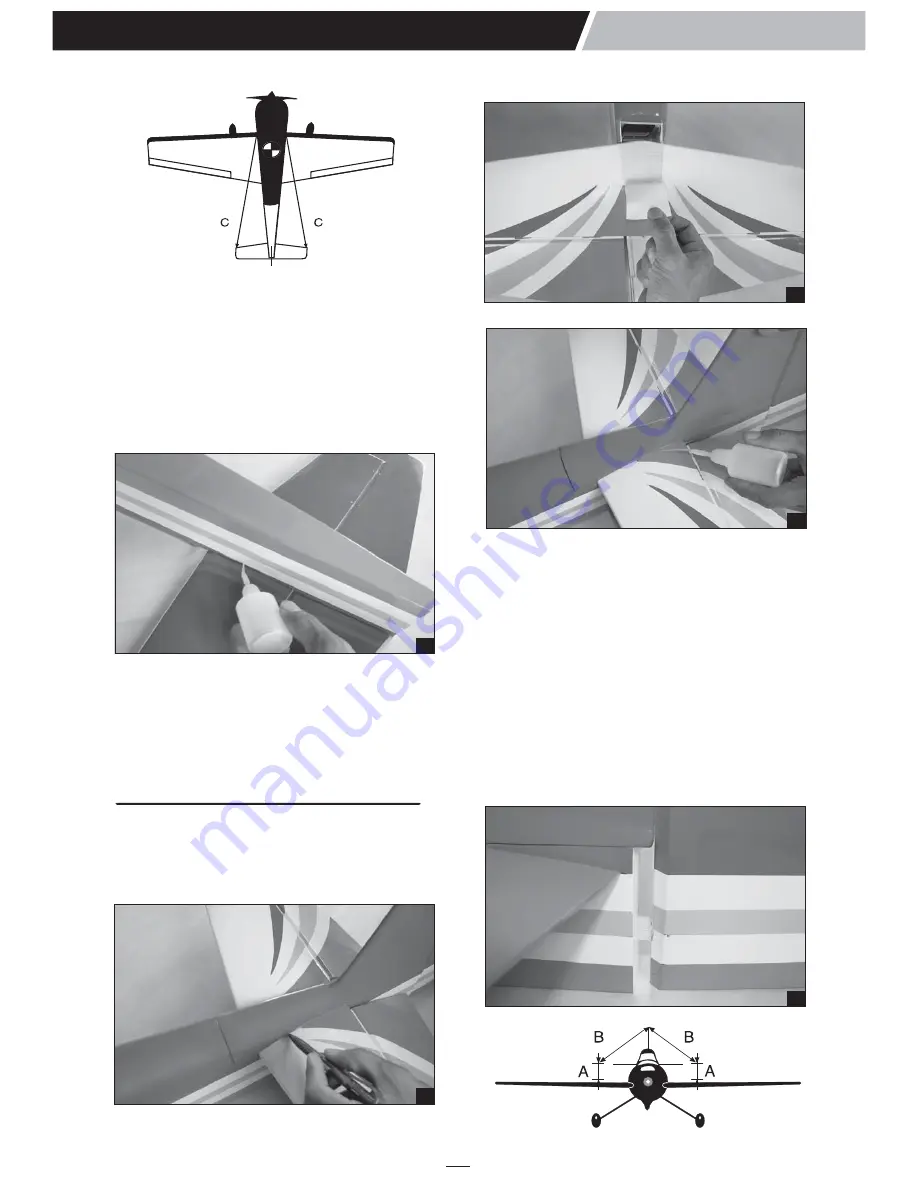

1. Using the block of the rudder as a guide and

mark the shape of it on the top of the elevator.

2. Remove the covering from the elevator and also

on the block of rudder.

23

24

25

3. Using a triangle, check to ensure that the

vertical stabilizer is aligned 90 degree to the

horizontal stabilizer.

4. When you are sure that everything is a aligned

correctly, mix up a generous amount of 30

minute epoxy. Apply a thin layer to the slot in

the mounting platform and to the vertical

stabilizer mounting area. Apply epoxy to the

lower rudder hinge. Set the stabilizer in place

and re-align. Double check all of your

measurements once more before the epoxy

cures. Remove any excess epoxy using a

paper towel and rubbing alcohol and hold the

stabilizer in place with T-pins or masking tape.

Allow the epoxy to fully cure before proceeding.

7

CAP 232

Instruction Manual

8. When you are sure that everything is aligned

correctly, mix up a generous amount of 30

minute epoxy. Apply a thin layer to the bottom

of the stabilizer mounting area and to the

stabilizer mounting platform sides in the

fuselage. Insert the stabilizer in place and

re-align. Double check all of your measurements

one more time before the epoxy cures.

Remove any excess epoxy using a paper towel

and rubbing alcohol and hold the stabilizer in

place with T-pins or masking tape.

22

26