onlinecomponents.com

P1 ENGRAVING UNIT

103072_00_en

PHOENIX CONTACT

13

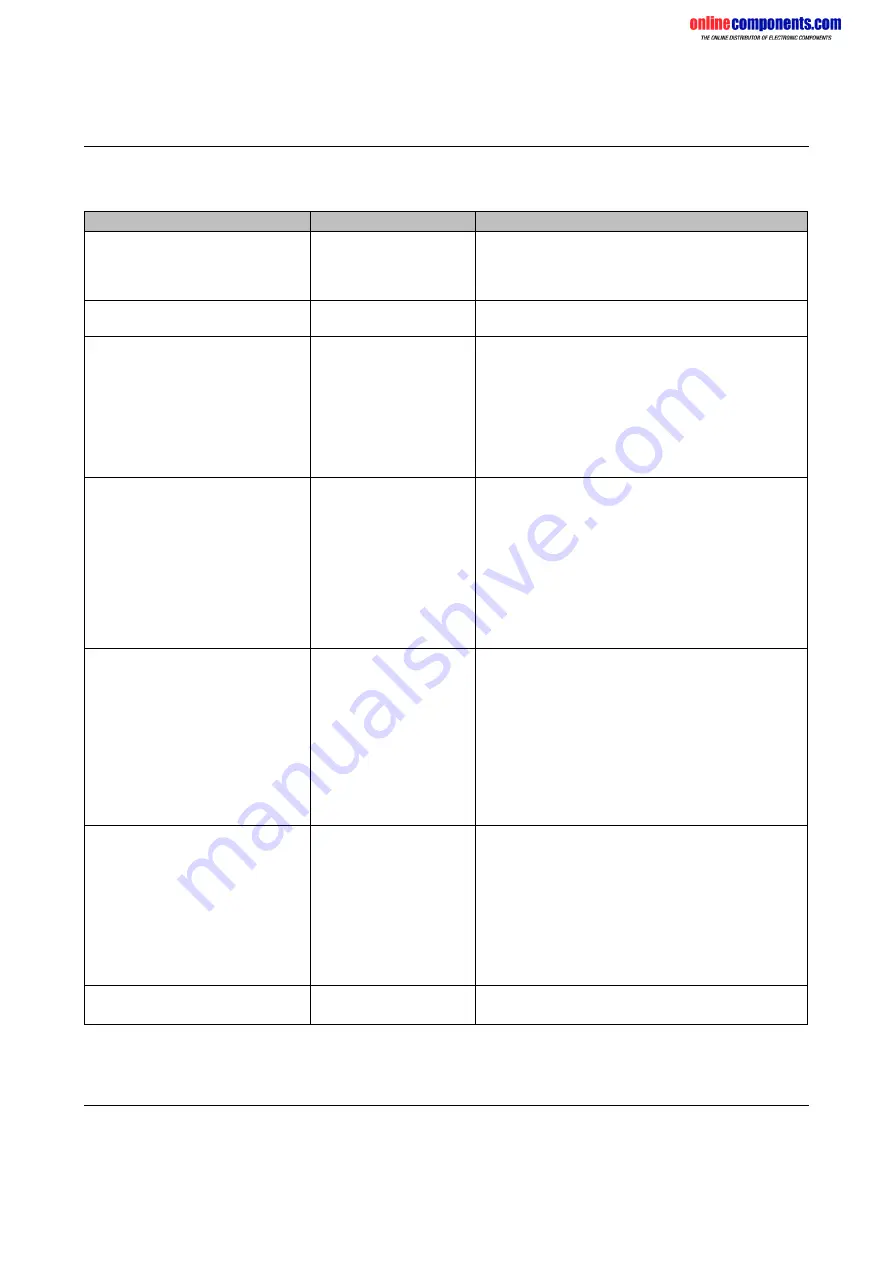

Troubleshooting

Error

Cause

Remedy

Unclean engraving, poor lettering

quality and/or burr formation on the

engraved characters.

Engraving shavings or

dust particles in the collet

chuck of the engraving

spindle.

•

Clean the collet chuck of the engraving spindle

(see page 12).

Poor lettering quality, uneven line

width, gaps in labeling.

Graver worn out or

clogged.

•

Replace graver (see page 10).

Engraving not visible.

Desired engraving depth not

achieved.

Insufficient engraving

depth.

•

Make sure that the depth adjuster is set correctly

with the adjustment aid (see page 11).

•

Check that the gap between the depth adjuster and

engraving material is around 2 mm.

To do this, manually move the engraving head

over the engraving material when the plotter is

switched off (see page 8).

•

Adjust the engraving depth (see page 10).

Red LED lights up on the control unit.

Engraving unit has aborted the

engraving procedure.

Engraving spindle is faulty

or an overload has

occurred.

•

To check, press the "ON" and "OFF" buttons on the

control unit simultaneously.

The vacuum cleaner continues running and the

engraving spindle switches on after a brief delay.

By pressing the "ON" or "OFF" button the speed of

the engraving spindle can be increased or

decreased in order to test the function of the

engraving spindle.

•

If the red LED is still lit up, the engraving spindle is

faulty and must be replaced.

Engraving unit will not switch on.

Green "Power" LED is not lit up on

the control unit.

Insufficient power supply.

Fuse has blown.

Power supply unit is faulty.

•

Check that the socket that is used is OK.

•

Check that the mains plug and connector are

connected correctly.

•

Check that the fuse in the mains connection of the

control unit is OK.

To do this disconnect the mains cable, remove the

fuse insert from below the mains switch, and

replace the fuse, if necessary (P1 ENGRAVING

FUSE 4A, Order No. 5145698).

•

Replace the power supply unit.

Engraving mode not possible.

•

Check that the connecting cable between the

control unit and plotter is connected.

•

Check that the engraving head has been fitted

correctly and that the cable to the engraving

spindle is connected.

•

Observe the notes for the CMS-MARK-WIN

software.

•

Note the order when switching on: switch the

controller on first, followed by the plotter.

Engraving unit does not respond to

data sent by the PC.

Data cable connected

incorrectly/faulty.

•

Check that the correct interface is set on the PC.

•

Check the data cable and replace, if necessary.