EDF ENR PWT

D06

‐

P06

‐

01

Indice

1

Date:

3

‐

01

‐

13

EDF

ENR

PWT

Société

par

actions

simplifiée

à

associé

unique

–

au

capital

de

37

505

000

€

‐

N°

513

281

972

RCS

NANTERRE

Siège

social

:

100

Esplanade

du

Général

de

Gaulle

–

Cœur

Défense

–

Tour

B

92932

Paris

La

Défense

cedex

.

33,

Rue

Saint

Honoré

‐

Z.I.

Champfleuri

38300

Bourgoin

Jallieu

‐

France

Tel

:

04

74

93

80

20

‐

Fax

:

04

74

93

80

40

Two specific grounding methods are recommended for Photowatt PV modules with 5 mm grounding holes,

as described below. Other grounding methods can be acceptable, provided they comply with all local

electrical codes and regulations.

Method A: Bolt + Nut with teeth + Cup washer.

A grounding kit with M5 size SS cap bolt, M5 size SS flat washer, M5 size SS cup washer, and M5 size SS

nut (with teeth) is used to attach a copper grounding wire to grounding hole on the frame (see picture

above).

Attach the wire between the flat washer and the cup washer. Ensure the cup washer is between the frame

and wire with concave side up to prevent corrosion due to dissimilar metal. Tighten the bolt securely using

the SS nut with teeth. A wrench may be used in this application. The tightening torque is 1 Nm.

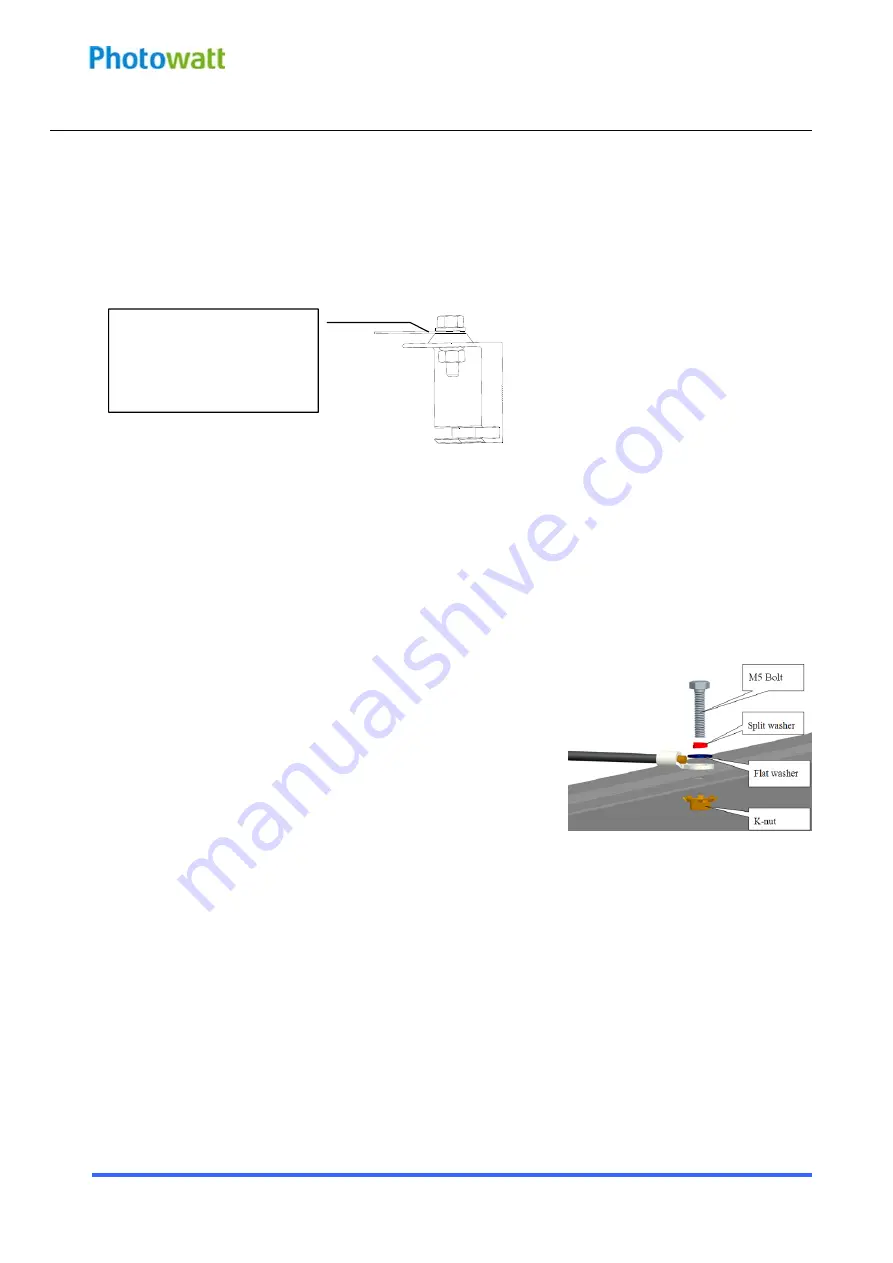

Method B: Bolt + K-nut + Ring terminal (copper).

Connect the grounding hardware (M5) to the grounding hole on the

frame as shown in the picture.

A K-nut is used to penetrate anodizing (protective coating) on the

frame to create conductive connection.

A torque moment of about 3 Nm should be used to fasten the

grounding parts to module frame.

Attach wire between the flat

washer and cup washer. Place cup

washer (concave side up) between

frame and wire.

6