EDF ENR PWT

33,

Rue

Saint

Honoré

‐

Z.I.

Champfleuri

38300

Bourgoin

Jallieu

‐

France

Tel

:

33

4

74

93

80

20

‐

Fax

:

33

4

74

93

80

40

EDF

ENR

PWT

Société

par

actions

simplifiée

à

associé

unique

–

au

capital

de

37

505

000

€

‐

N°

513

281

972

RCS

NANTERRE

Siège

social

:

100

Esplanade

du

Général

de

Gaulle

–

Cœur

Défense

–

Tour

B

92932

Paris

La

Défense

cedex

.

D07-P0

6-01

GB

Ind

ice

1

Date

:

3

-01-13

ANNEX B: ALTERNATIVE GROUNDING METHODS

All the requirements of paragraph 5.2 should apply to the alternative grounding methods. Each method has

been qualified by at least one North-American certification body, as specified.

For grounding methods A and B, connect module frames to each other using suitable grounding conductor

with ring terminals.

A copper terminal ring is recommended (please see below picture for reference). The d2 diameter should be

5.3mm and the size of d1 is determined by the size of the grounding cable. Proper crimping tool and method

should be used to crimp the terminal onto the grounding cable. Once crimped, each terminal should be

visually checked according to the following points:

1.

The insulator jacket is correctly crimped in

the first collar

2.

The conductor core is correctly crimped in

the second collar

3.

The conductor core does not run over the

functional part of the ring terminal

4.

The ring terminal should not be bent or

deformed during the crimping operation.

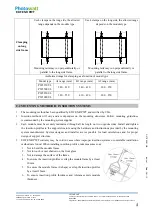

GROUNDING METHOD B: Bolt + K-nut + Ring terminal (copper)

When diameter of the grounding holes is 5mm

Connect the grounding hardware to the grounding hole on the frame as

shown in the picture.

A K-nut is used to penetrate the frame’s anodizing (protective

coating) to create conductive connection.

A torque moment of about 3Nm should be used to fasten the

grounding parts to module frame.

ANNEX C: ALTERNATIVE MOUNTING METHODS

All the requirements of paragraph 6.0 should apply to the alternative mounting methods, unless otherwise

specified.

C.1 MOUNTING METHOD A: CLAMPING

The mounting method has been qualified by EDF ENR PWT and certified by CSA.

Top or bottom clamping methods will vary and are dependent on the mounting structures. Follow mounting

guidelines recommended by the mounting system supplier.