EDF ENR PWT

33,

Rue

Saint

Honoré

‐

Z.I.

Champfleuri

38300

Bourgoin

Jallieu

‐

France

Tel

:

33

4

74

93

80

20

‐

Fax

:

33

4

74

93

80

40

EDF

ENR

PWT

Société

par

actions

simplifiée

à

associé

unique

–

au

capital

de

37

505

000

€

‐

N°

513

281

972

RCS

NANTERRE

Siège

social

:

100

Esplanade

du

Général

de

Gaulle

–

Cœur

Défense

–

Tour

B

92932

Paris

La

Défense

cedex

.

D07-P0

6-01

GB

Ind

ice

1

Date

:

3

-01-13

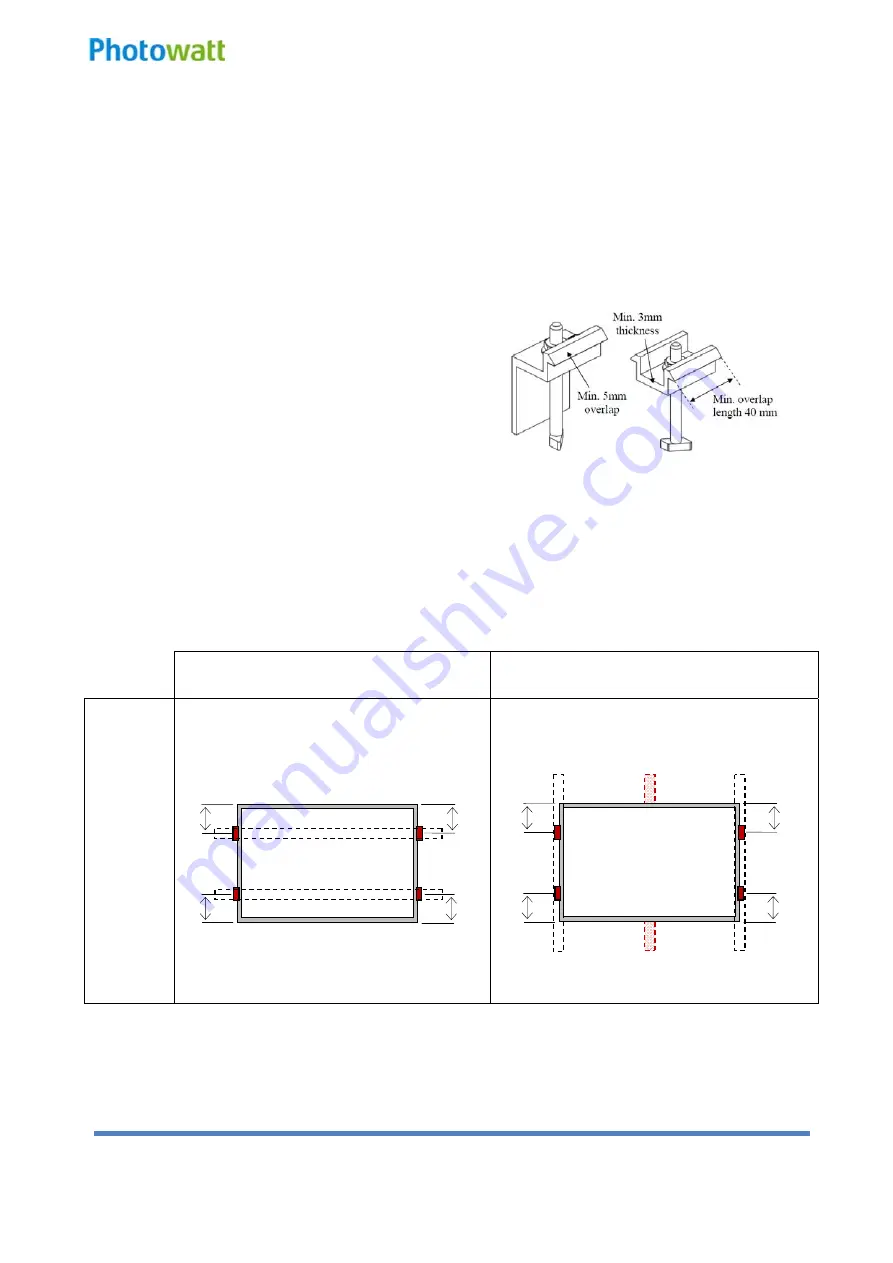

Each module must be securely fastened at a minimum of 4 points on two opposite sides. The clamps should

be positioned according to the authorized position ranges defined in table C-1. Install and tighten the

module clamps to the mounting rails using the torque stated by the mounting hardware manufacturer.

System designer and installer are responsible for load calculations and for proper design of support

structure.

EDF ENR PWT warranty may be void in cases where improper clamps or unsuitable installation methods

are found. When installing inter-modules or end type clamps, take measures so as:

1.

Not to bend the module frame

2.

Not to touch or cast shadow on the front glass

3.

Not to damage the surface of the frame

4.

To ensure the clamps overlap the module frame

by at least 5 mm.

5.

To ensure the clamps overlap length is at least

40 mm.

Clamp material should be anodized aluminum alloy. Floating type clamps are not authorized.

Clamp positions are of crucial importance for the reliability of the installation, the clamp centerlines must

only be positioned within the ranges indicated in table C-1, depending on the configuration and load.

For configurations where the mounting rails run parallel to the clamps installation side, precautions should

be taken to ensure the module frame (C-shape) overlap the rail by 15mm or more.

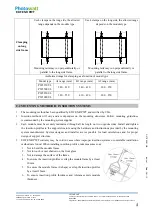

Table C-1: Authorized attachments for clamping method

Uplift load

≤

2400 Pa

Downforce load

≤

2400 Pa

Uplift load

≤

2400 Pa

2400 Pa

≤

Downforce load

≤

5400 Pa

Clamping

on short

side frame

Use 4 clamps on the short side, the allowed

range depends on the module type. Mounting

rails may run parallel or perpendicularly to the

short side frame

Use 4 clamps on the short side, the allowed

range depends on the module type. An additional

support bar should be placed below the module.

Mounting rails should run parallel to the short

side frame