D81-P06-01 GB R5

28/07/2020

www.photowatt.com

8

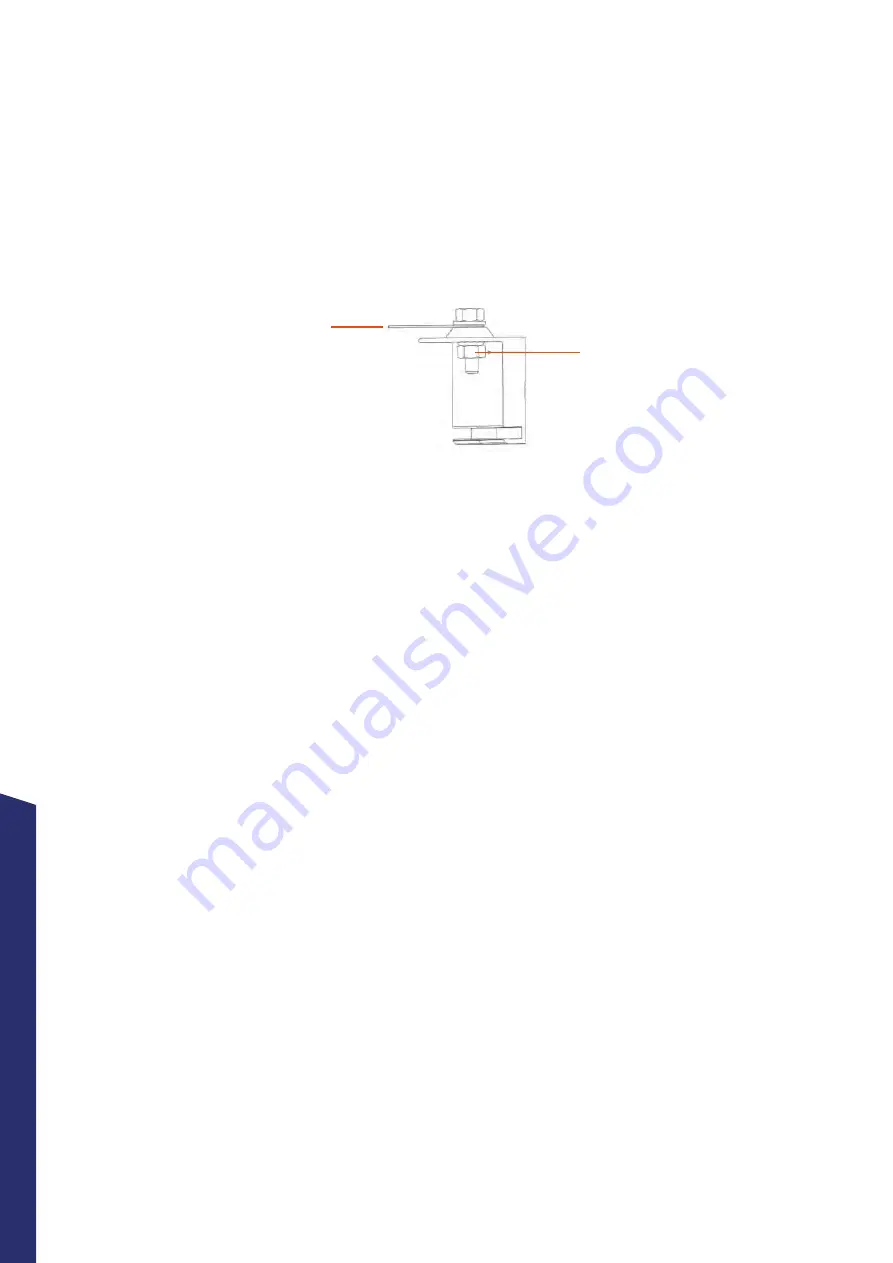

1. To fix the wire between the

flat washer and cup washer,

place the cup washer

(concave side up) between

the frame and the wire.

2. Then tighten the bolt

using the toothed nut.

•

Standard modules can be installed in either

landscape or portrait orientations. Refer to

the detailed instructions for further guidance.

Please note that in areas with heavy snowfall (>

2400 Pa) further countermeasures such the use

of additional support bars should be conside-

red to avoid snow loads damaging the lowest

row of modules.

•

In cases where an additional support bar is re-

commended to improve both mechanical sta-

bility and long-term module performance, we

recommend selecting a sufficiently resistant

material. EDF ENR PWT recommends bars with

a minimum thickness of 50mm (1.97 in). The

support bar centerline should be positioned

within 100 mm (3.94 in) of the side frame cen-

terline (slight shifts may be necessary to access

module grounding holes).

•

The load described in this manual corresponds

to test load. For installations complying with IEC

61215-2:2016 and UL 1703, a safety factor of 1.5

should be applied for calculating the equivalent

maximum authorized design loads. Project de-

sign loads depend on construction, applicable

standards, location and local climate. Determi-

nation of the design loads is the responsibility

of the racking suppliers or professional en-

gineers. For detailed information, please follow

local structural code or contact your professio-

nal structural engineer.

6.1

MOUNTING METHOD : BOLTING

•

The mounting method has been qualified by

EDF ENR PWT, as well as certified by VDE and

CSA.

•

Modules should be bolted to support structures

through the mounting holes in the rear frame

flanges only.

•

Each module must be securely fastened at a mi-

nimum of 4 points on two opposite sides.

M8 X 1.25 (5/16”) bolt and nut should be used.

The yield strength of bolt and nut should not be

less than 450 MPa.

•

Tightening torques should be within 17~23 Nm

(12.5~17.0 ft-lbs) for M8 (5/16”) coarse thread

bolts, depending on bolt class.

•

In areas with heavy wind loads, additional

mounting points should be used. The system

designer and the installer are responsible for

calculating the load and ensuring that the sup-

port structure meets the requirements.

Summary of Contents for PW60HT-C-XF

Page 1: ...INSTALLATION MANUALS For professional use only...

Page 2: ...INSTALLATION MANUAL FOR STANDARD MODULES For professional use only...

Page 27: ...INSTALLATION MANUAL OF DOUBLE GLASS MODULES For professional use only...

Page 42: ...INSTALLATION MANUAL OF BIFACIAL MODULES For professional use only...