33

Owner’s Manual

ENGLISH

Using the Quick-Release axle

Available as an option with the Neox Dynamic wheelchair, the Quick-Release Axle

can be installed to facilitate the removal and installation of the propulsion wheels.

Removal of the wheels can be done in three easy steps.

1.

Disengage

wheel locks. Depending

on the type of wheel lock installed,

either push or pull the handle to

disengage wheel locks.

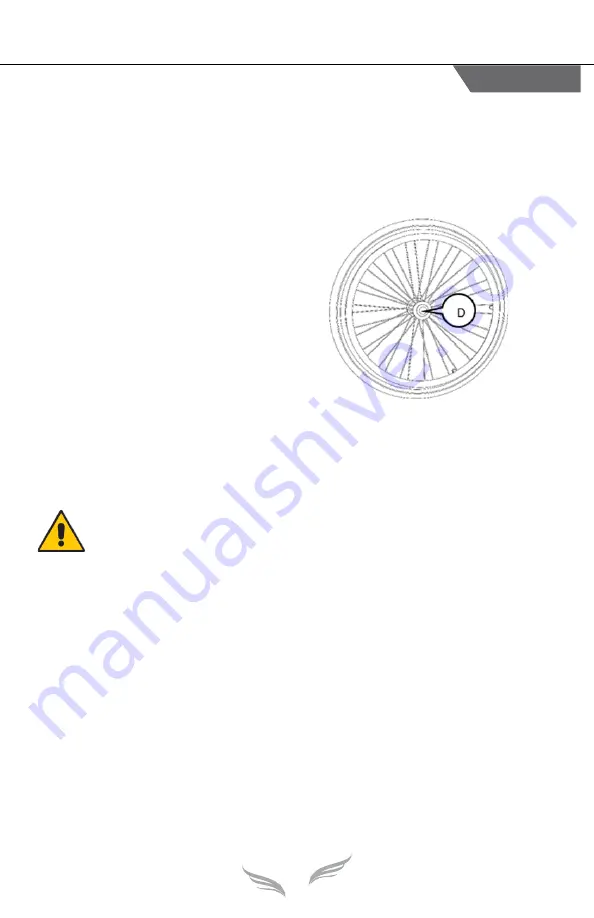

2. Press down on the quick-release

button

D

at the center of the wheel.

3. Hold button

D

down and remove the

wheel by pulling outwards.

To reinsert wheel, hold button

D

down and reinsert axle.

Note

- Make sure retaining balls project completely out from the axle bushing and

the tip of the ball lock pin is aligned with the tip of the axle before using your

wheelchair.

WARNING

•

After all adjustments or reinstallation of the propulsion wheels, always

make sure the retaining balls of the quick release axle project completely

out from the axle bushing and that the tip of the ball lock pin is perfectly

aligned with the tip of the axle before using your wheelchair.

•

Keep quick-release axles clean and free of dust or lint to ensure its proper

operation. Lubricate if necessary.

•

Always make sure the wheels are securely locked before using your

wheelchair, an unlocked wheel may detach during use if not properly

secured and can result in a fall.

Propulsion wheel horizontal positioning

The horizontal position of the propulsion wheel directly affects the wheelchair’s

stability. Placing the propulsion wheel toward the front, has the disadvantage of

reducing wheelchair stability but has the advantage of facilitating propulsion.

Finding the right position to maximize stability and ease of use is essential. The

different adjustments available on the Neox Dynamic wheelchair provide a wide

range of positioning options to better accommodate the needs of each individual.

R

e

vision 0

July

202

2