phytron

MA 1203-A010 EN

9

2 In-Vacuum Stepper Motors and Cryo Stepper Motors

Phytron VSS stepper motors for in-vacuum and Cryo applications are precision drives with

protection class IP20. According to the vacuum class, the motors are designed for different

temperature, pressure and radiation ranges, see section 10.1. Cryo stepper motors are

ultra high vacuum stepper motors for operation e.g. in liquid nitrogen or liquid helium.

In-vacuum and Cryo stepper motors are manufactured, cleaned, tested and packed with

great care and accuracy. A 3-stage package protects the stepper motor against contami-

nation, moisture and mechanical damage.

On opening the packaging, several precautions must be observed (section 3) to maintain

the defined stepper motor's specifications and functionality.

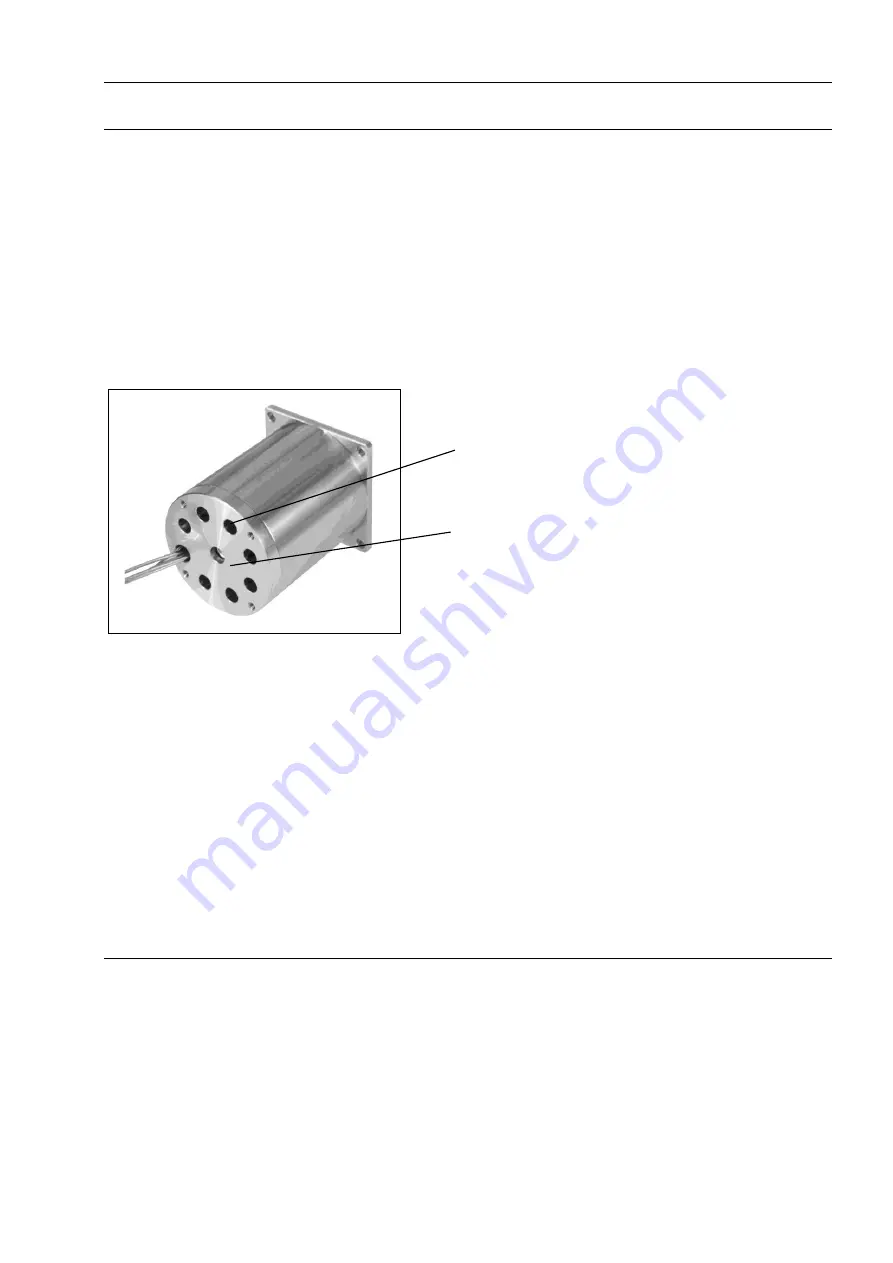

Outgassing hole

Engraved

serial number

Fig. 1 : In-vacuum or Cryo stepper motor

– rear view

i

The two most important rules for handling in-vacuum and Cryo step-

per motors:

- Do not touch the stepper motor with bare hands!

- Take care that no particles or moisture can get inside the motor

through the outgassing holes.

2.1 Heating in Vacuum Environment

Normally, the heat generated by a stepper motor in a vacuum is largely dissipated by con-

duction through the mounting surface; heat dissipation by convection and radiation are

negligible. To avoid overheating the motor, the maximum specified temperatures (sec-

tion10.1 ) must be taken into account when determining duty cycles for setting the peak,

run and stop (holding) current values.