2. Load

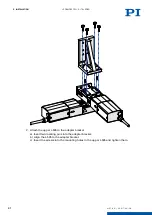

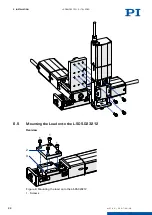

3. Motion platform of the L-505.023212

Tools and Accessories

■

At least 3 screws with suitable

■

Suitable tools for tightening the screws

■

Optional: 2 suitably dimensioned dowel pins as locating pins for aligning the load on the

L-505.023212

Requirements

✓

You have read and understood the

general safety instructions (p. 8)

✓

You have mounted the L-505.023212

properly.

✓

The L-505.023212 is not connected to the electronics.

✓

You have prepared the load so that it can be fixed to the mounting holes on the motion

platform:

■

The distance between the center of gravity of the load and the center of the motion

platform is as small as possible in all directions.

■

At least three points are provided for fixing the load on the motion platform.

NOTICE

Impermissibly high load on the L-505.023212

An impermissible high load impairs the motion of the platform and can damage the

L-505.023212.

►

Pay attention to the

maximum permissible forces (p. 32)

that may act on the motion

platform.

►

In the case of multi-axis systems, include the masses of the positioners to be moved

when calculating the load.

NOTICE

Excessively long screws and locating pins

Screws and locating pins that are inserted too deeply can damage the L-505.023212.

►

Pay attention to the

depth of the mounting and locating holes (p. 35)

►

Only use screws and locating pins of the correct length for the respective mounting holes.

Fixing the Load

1. If necessary: Insert the locating pins into the corresponding holes in the motion platform.

2. Align the load on the motion platform so that the mounting holes selected in the motion

platform can be used for mounting the load.

3. Place the load onto the motion platform so that the locating pins are inserted into the

corresponding locating holes in the load.

4. Tighten the screws in all mounting holes.

5. Check that the load is fixed firmly to the motion platform.

6 INSTALLATION

L505M0017EN

‒

3/18/2020

23

M O T I O N | P O S I T I O N I N G